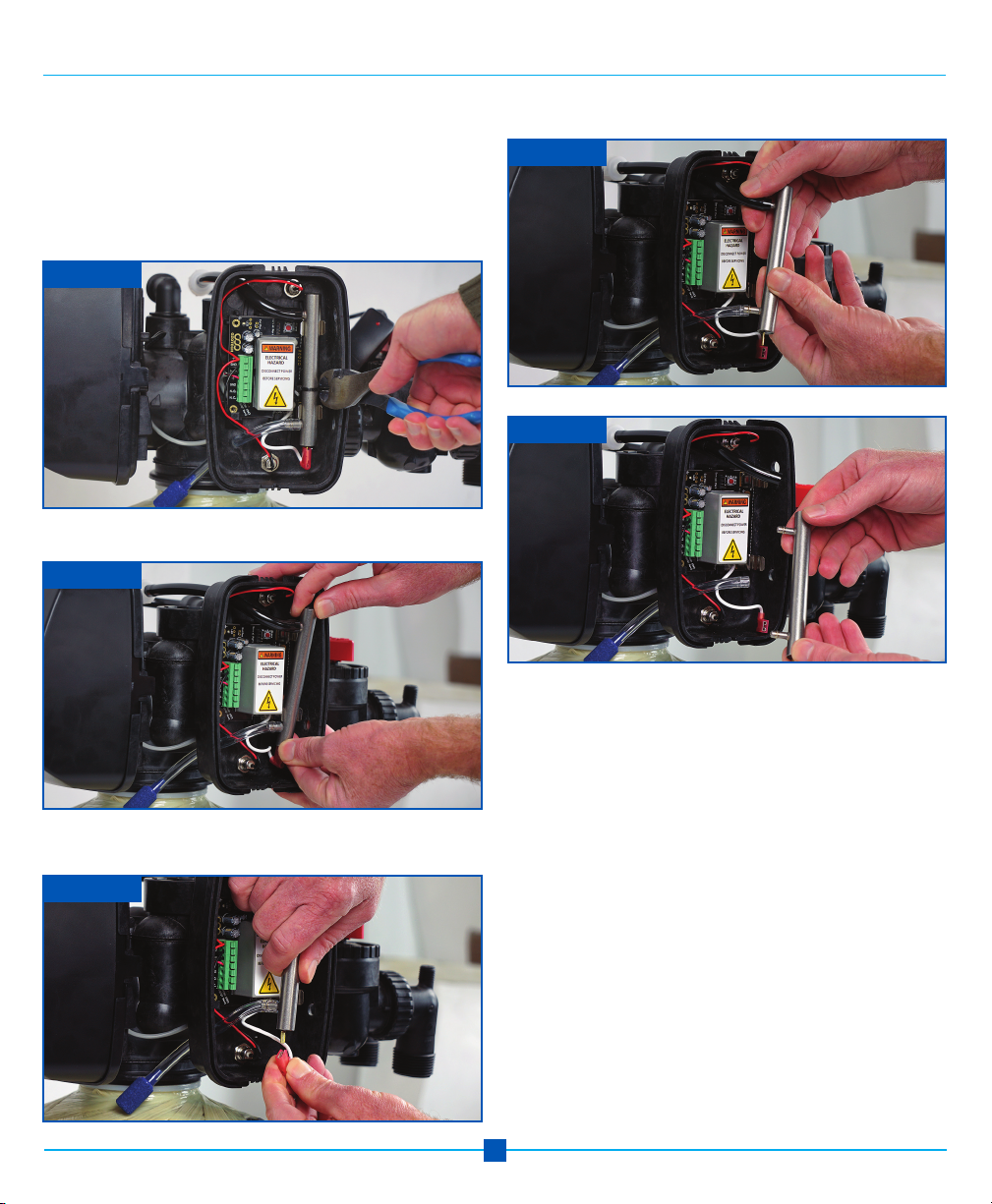

-5- AIO-OZONE Installation & Programming Guide

Power Supply Jack

Power Supply Jack

for Control Valve

Installation of EOG Unit continued

EOG Unit Indicator Light- Photo 1

Green Light Blinking Slowly - Standby mode

Green Light Blinking Quickly - High voltage startup

Green Light Solid - High voltage is ON & stable; CD cell

producing ozone

Red Light Solid - Unstable high voltage; CD cell may

need cleaned

Green/Red Light Alternating Twice/Second - HV is ON,

but current is low

Red Light Flashing - NO or NC contacts are shorted

Orange Light - 1 year timer has expired; clean CD cell,

then push reset button to reset timer Photo 2.

Note: Holding reset for 3 seconds will change pulsing

green LED to solid green if the cell is in good operating

order. If LED changes to solid red, the cell needs cleaned.

Photo 2

Photo 1

Step 17: For Nelsen Unit using the integrated power sup-

ply cord connect the control valve power supply cord to

the power supply jack. Plug in the EOG to the wall outlet.

Once you power either system, the pulsing green LED

may turn to pulsing orange. Pressing the reset button will

reset it to pulsing green.

Nelsen EOG Model

At this point installation of your Enhanced Oxidation Gen-

erator is complete. Continue to page 8 for programming

instructions.

Flashing Green/Red means that the circuit is looking for

an optimum frequency to operate within. It is still making

ozone in the mode and will eventually go to solid green

or red.