6

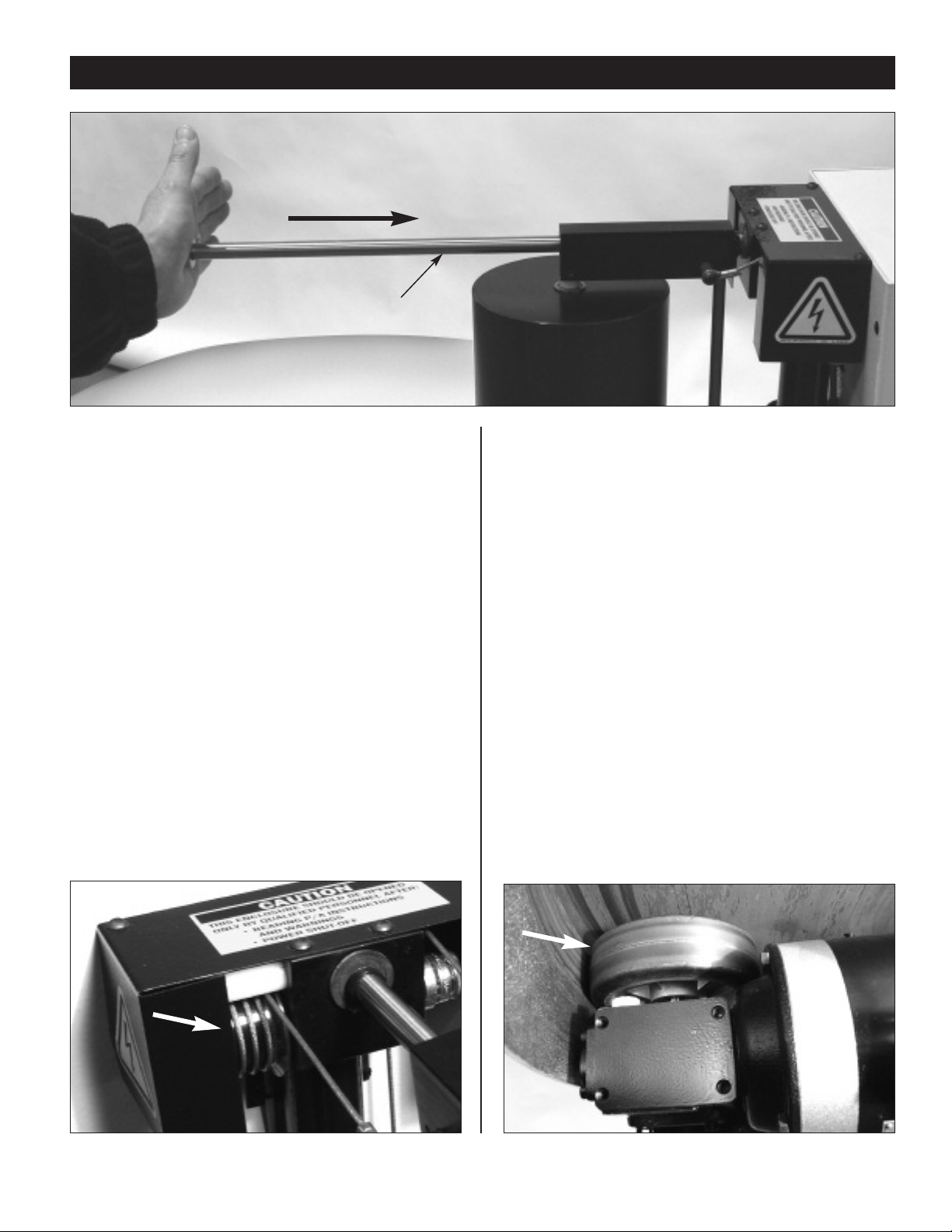

You may estimate this distance before positioning the

Pallet Reel by pulling off a strip from the coil to be used,

manually twist to 1/4 turn and measure the distance

needed to achieve an easy transition. Place the Control

Head of the Pallet Reel at this approximate measured

distance from the forming equipment.

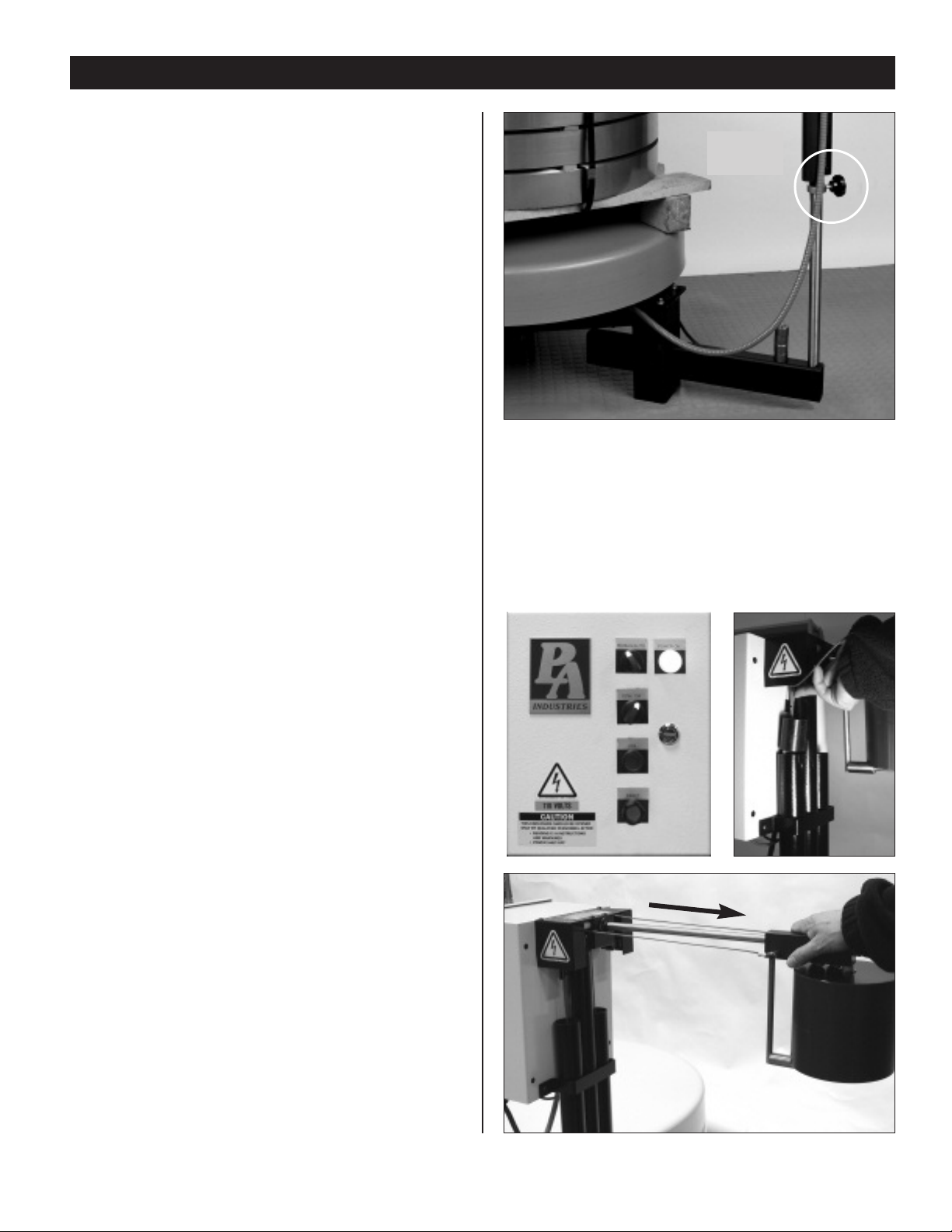

OPERATIONS START-UP

Before beginning production with the Pallet Reel, complete

the following steps to ensure a safe and successful start-up.

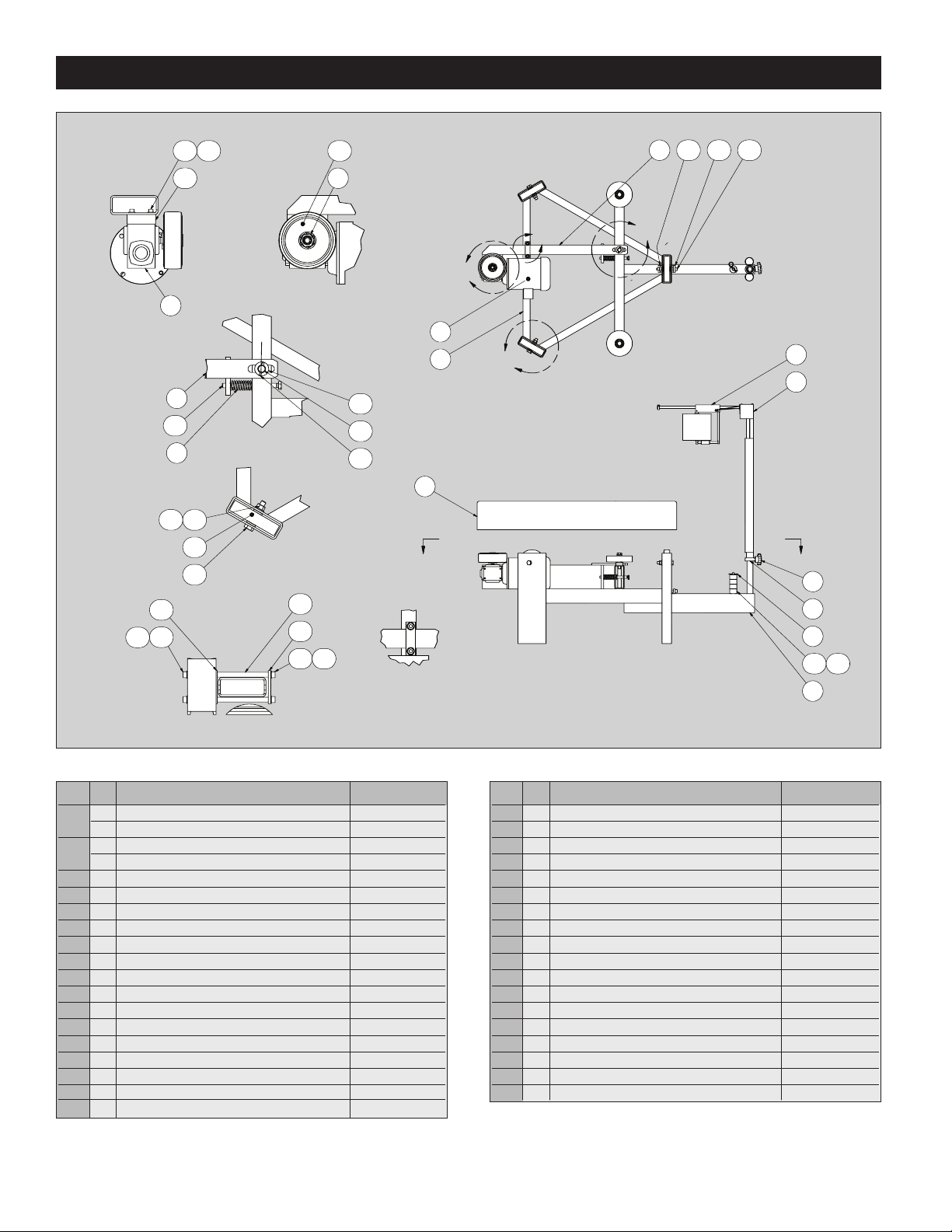

Positioning (Refer to Figure 4))

Make sure the Pallet Reel is oriented so that the Control

Head Mast is aligned with the feed entry to the forming

equipment. Also, make sure that the table is placed to

accommodate the wind direction of the coils to be fed.

It is best to check positioning at this stage rather than later

when the pallet load is on the turntable.

Clockwise/Counter-Clockwise (CW/CCW) Rotation

Examine the coils to be fed to determine the unwind

direction. Determine if the coil will rotate in a CW direction

or a CCW direction.

Set the CW/CCW Switch on the Motor Control Box to the

appropriate setting. Change setting of this switch only

when table rotation has stopped.

Loading

Load the pallet of coiled materials, being careful not to

strike the Control Head Assembly. The top portion of the

Control Head can be swiveled to the left or right to position

it away from the loading side.

Center these coils on the turntable with eyesight accuracy.

The Pallet Reel can tolerate a small amount of off-center

loading, however too great a miss-alignment will create an

oscillating rotation of the coils which will cause uneven

feeding and uneven loading on the Pallet Reel frame and

tabletop.

Be aware of the difference between centering the coil and

centering the pallet. Coils are not always centered on the

PALLETIZER

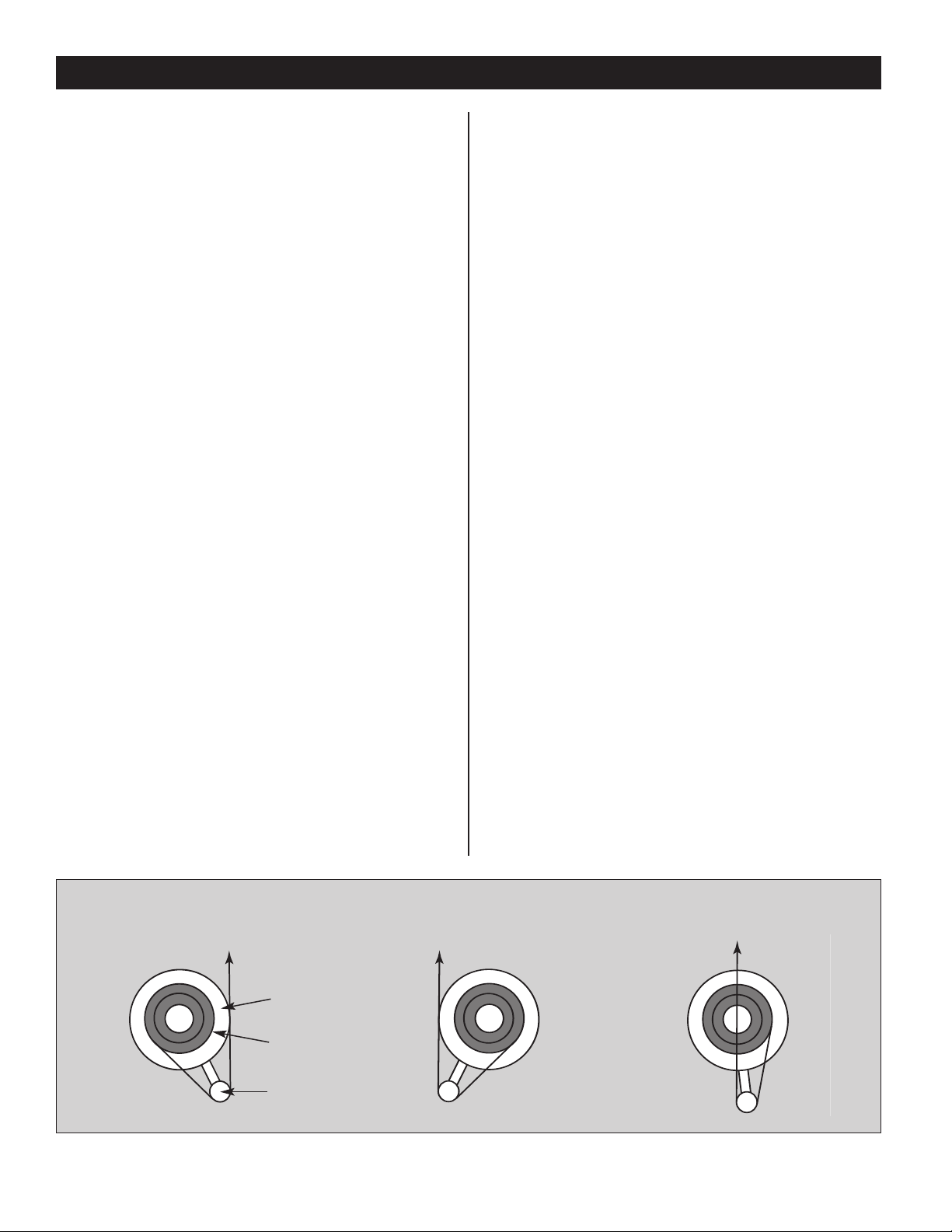

Position 1 – Right Position 2 – Left Position 3 – Center

Figure 4

Control Head

Material

Table

Material Feed

Direction

The Safety Interlock Circuit will allow you to shut down the

production equipment used in conjunction with the Pallet

Reel if the Pallet Reel detects a Drive Fault or a material

tight loop condition. There is a pre-wired circuit in the

Pallet Reel that requires connection to associated

production equipment.

Control Head Position (Figure 4)

The Control Head should always be aligned with the

production equipment feed entry so that the strip loop will

follow a straight run from the Pallet Reel Guide Drum

directly to the forming equipment entry. This alignment can

be done by visual line of sight from Control Head Mast to

feed entry.

Table Position (Figure 4)

The diagrams demonstrate the various material flow

options available. Although feeding the coil strip directly

back over the coil stack (Position 3) is a feasible option, it

is not highly recommended. Unwinding off to either side is

preferred since this reduces the opportunity for tangling

the strip on the coil stack and damaging the strip edge.

Also, offcenter feeding will allow a more parallel pull of

the strip from the coil.

Distance from Forming Equipment

The distance required between the Pallet Reel and the

forming equipment will depend on the characteristics of the

coil strip being used. There is no specific rule or formula

for this determination.

The strip material passes around the Pallet Reel Guide

Drum in a vertical position. As it feeds to the forming

equipment it will transition to a horizontal plane requiring

a1/4 turn or twist either to the left or right. The distance

required to achieve this twist easily,without kinking or

bending, will determine the position for the Pallet Reel.

Lighter, thinner materials will transition very easily and will

require little more than the 42" footprint of the Pallet Reel

itself. Heavier, thicker materials will require more loop

length to achieve the 1/4 twist and more set back will be

required.

You may estimate this distance before positioning the