EN

AS Strömungstechnik GmbH

www.asstroemungstechnik.de

Version date: 09/2020

6

2 Safety

Please observe the following notes to pre-

vent malfunctioning, damage and injuries.

2.1 Intended use

The M2-Series dispense heads are de-

signed for the clean and safe dispensing/

withdrawal of neutral or inorganic liquid

chemicals from transport containers which

do not adversely affect the physical and

chemical properties of the materials and

substances of which the dispense head

used is composed.

The M2-Series conductive dispense heads

are designed for the clean and safe dis-

pensing/withdrawal of neutral or organic

liquid chemicals from transport containers

which do not adversely affect the physical

and chemical properties of the materials

and substances of which the dispense

head used is composed. They are electro-

statically safe in the sense of the Cenelec

Technical Report TR 50404: 2003 and

therefore applicable in zones 1 and 2 for

liquids of the entire explosion group IIA.

Dispense heads may be used only in con-

junction with AS dip tubes of the series

corresponding to the dispense head. Ob-

serve the operating instructions of the dip

tube.

The dispense heads are designed for use

with pump systems.

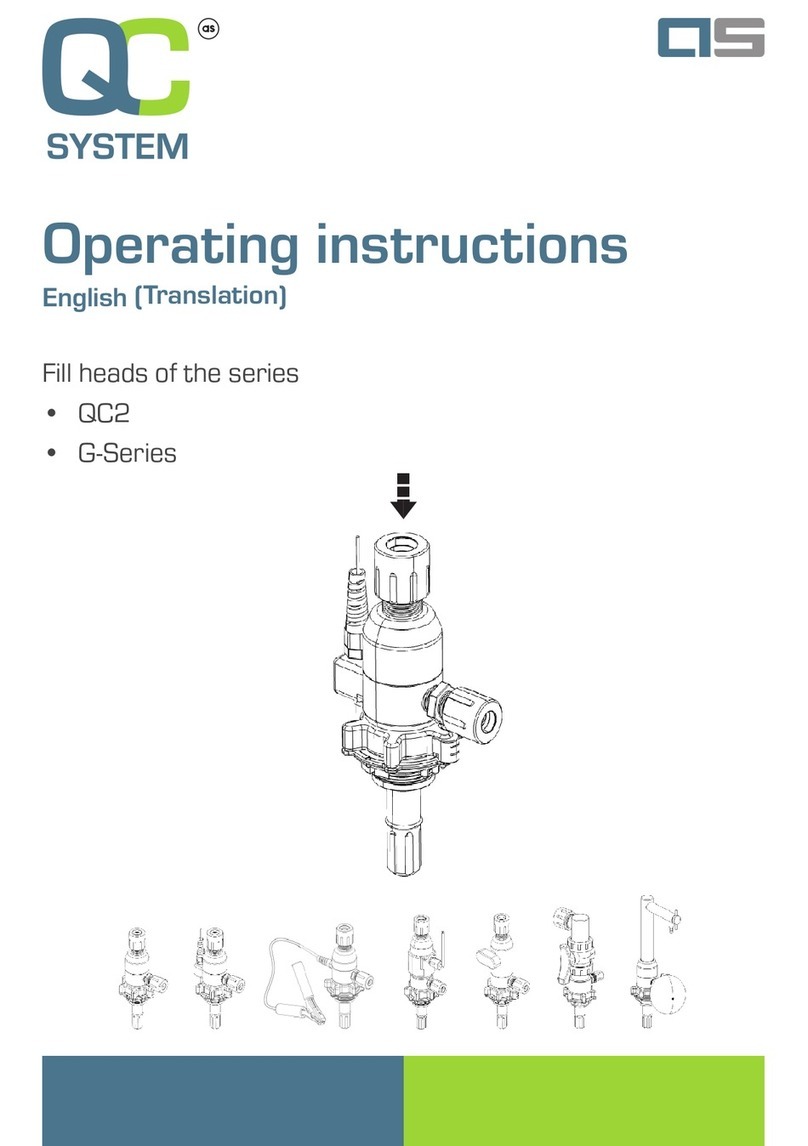

For lling and recirculation applications,

refer to the operating instructions for ll

heads of the corresponding series.

2.2 Improper use

Any use other than the one described in

the Section “intended use” is deemed to

be inappropriate use. The operator of the

products shall be solely responsible for any

resulting damage.

2.3 Responsibility of the user

Operator means any natural or legal per-

son who operates or controls the device or

makes it accessible to third parties for use

and who is responsible for the safety of the

user or third parties.

• In particular, observe the general

safety and occupational safety regula-

tions of the BG Chemie in Germany or

the responsible regional professional

association for chemistry and health

(e.g. OSHA in the United States), the

applicable technical rules for haz-

ardous substances, the Hazardous

Substances Ordinance, the CLP Or-

dinance, the company own standard

operating procedures (SOPs), as

well as the regulations of the ATEX

Directive, the technical guidelines

“Flammable liquids” and the explosion

protection guidelines of the BG Che-

mie in Germany or the responsible

regional association / authority for

applications in hazardous areas.

• These operating instructions do not

replace the company’s own standard

operating procedures (SOPs).

• Wear appropriate protective clothing

when handling chemical substances.

Safety