3

1Notes on the Operating Manual ............................................................................................................5

1.1 Explanations of the safety warnings.................................................................................................. 6

1.2 General safety instructions ................................................................................................................ 7

1.3 Repairs............................................................................................................................................... 8

2Confirmation ...........................................................................................................................................9

3Transport, scope of delivery, installation..........................................................................................10

3.1 Packaging........................................................................................................................................ 10

3.2 Transport.......................................................................................................................................... 10

3.3 Temperature fluctuations and condensed water ............................................................................. 10

3.4 Conditions for the place of installation............................................................................................. 10

3.5 Installation of the machine............................................................................................................... 10

3.6 Type plate description...................................................................................................................... 10

3.7 Electrical connection........................................................................................................................ 11

4Technical data.......................................................................................................................................11

4.1 Use of the machine for the intended purpose.................................................................................. 12

4.2 Emissions......................................................................................................................................... 12

4.3 Degree of protection ........................................................................................................................ 12

4.4 Drive output...................................................................................................................................... 12

4.5 Rotation speed................................................................................................................................. 13

4.6 Rated power .................................................................................................................................... 13

4.7 Feed size ......................................................................................................................................... 13

4.8 Receptacle volume.......................................................................................................................... 13

4.9 Dimensions and weight.................................................................................................................... 13

4.10 Required floor space........................................................................................................................ 15

5Operating the machine ........................................................................................................................16

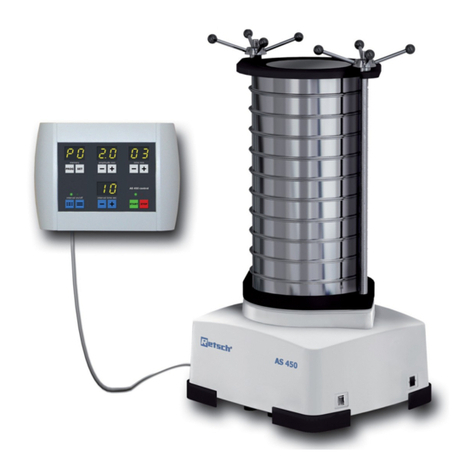

5.1 Views of the Instrument................................................................................................................... 16

5.2 Overview table of the parts of the device ........................................................................................ 17

5.3 Operating elements and displays .................................................................................................... 18

5.4 Overview Table of the Operating Elements and the Display........................................................... 18

5.5 Mounting the dividing head/dg_bm "text_mod_1315215336450_0001">....................................... 18

5.6 Inserting sample vessel................................................................................................................... 19

5.6.1 Inserting the sample container into the quick-release sample outlet........................................... 20

5.7 Switching On and Off....................................................................................................................... 21

5.8 Starting, Interrupting, Stopping........................................................................................................ 21

5.8.1 Starting......................................................................................................................................... 21

5.8.2 Interrupting................................................................................................................................... 21

5.8.3 Stopping....................................................................................................................................... 21

5.9 Process Run Duration...................................................................................................................... 22