Pacbrake is a registered trademark of Pacbrake Co.

HP625 AIR COMPRESSOR KIT L6210

2

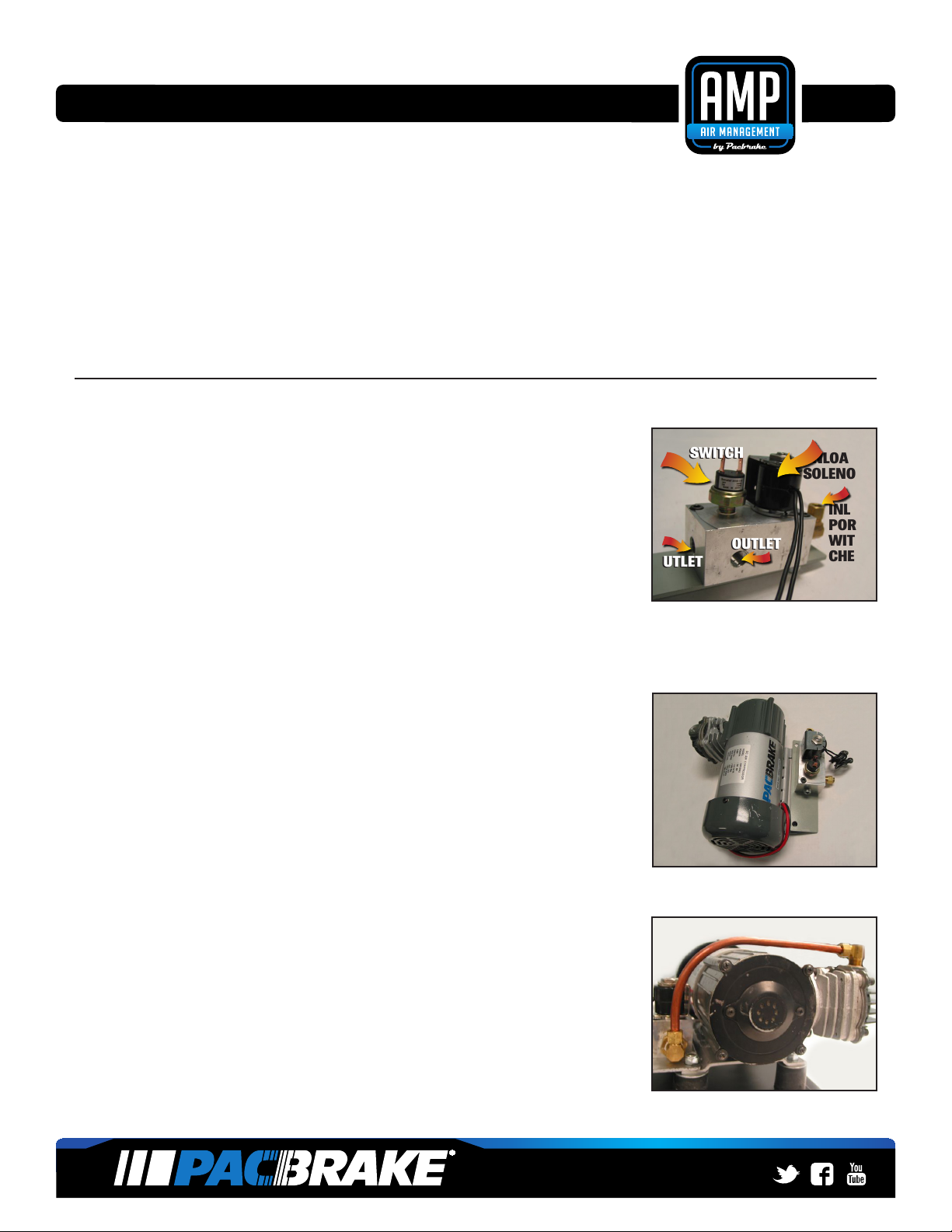

PRESSURE

SWITCH

OUTLET

OUTLET

UNLOADER

SOLENOID

INLET

PORT

WITH

CHECK

VALVE

PLUMBING THE AIR COMPRESSOR

1 Once the air compressor mounting location has been chosen

and the mounting holes are drilled, the manifold can be installed.

The air manifold assembly is mounted to the top of the two

mounting feet on the discharge side for vertical head and the

opposite side of the head for horizontal head models. The air

manifold provided contains a pressure switch, unloader valve,

one way check valve, one air inlet port and two air outlet ports.

2 Itiseasiertoinstallthetwoairoutletportttingsbeforemounting

the manifold to the compressor. One outlet port is the air supply

to the tank and the other port can be used to supply air to an

accessory, a gauge or be plugged off for future use (a ¼” NPT

plugisprovided).UsethreadsealantorTeontapeonallttings

installed to prevent air leaks.

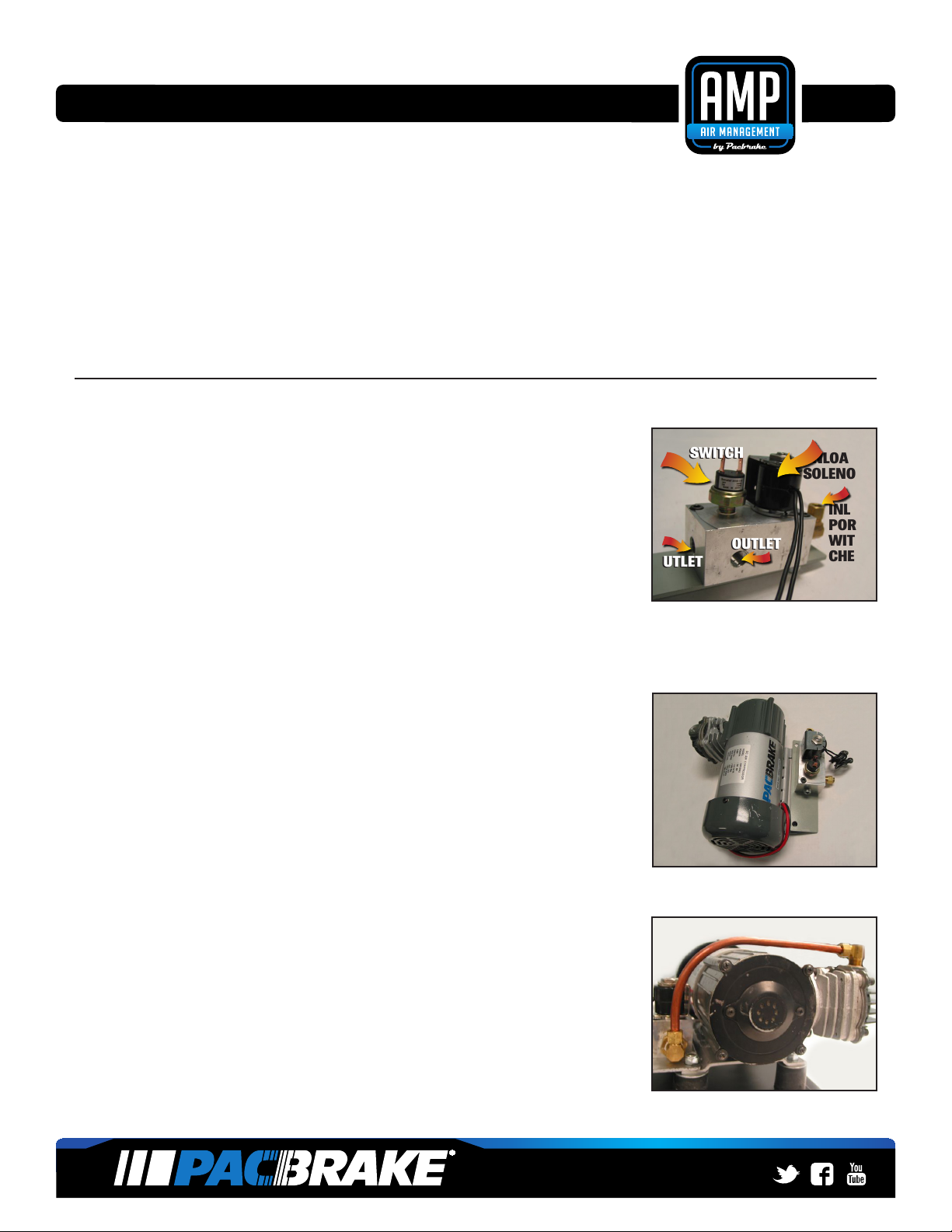

3 Usingthettingsprovided,connectthecopperdischargelinefrom

the compressor head to the manifold inlet port. The length of

copper line is designed for the horizontal compressor head.

Vertical head installations will require this line to be cut before the

bend with a tubing cutter.

Thank you and congratulations on the purchase of a Pacbrake air compressor with unloader installation kit. This kit

contains the basic electrical system and plumbing components needed to operate the air compressor.

Please read these instructions carefully to ensure you can complete the installation once started.

NOTE:Thiskitincludes“pushtoconnect”airlinettings.Theyrequiretheendoftheairlinetoberound,squareand

cleanly cut to ensure the internal seal will not leak air. The airline must only be cut with a sharp razor knife. Using

scissors, a hose cutter, or wire cutters will distort the airline causing the connection to leak air past the o-ring seal.

1

2

3

PRESSURE

SWITCH

OUTLET

OUTLET

UNLOADER

SOLENOID

INLET

PORT

WITH

CHECK

VALVE