INSTALLATION MANUAL - PACBRAKE ONBOARD AIR SYSTEMS, L6127

INSTALLATION MANUAL - INSERT TITLE HERE, L1234

PG 3

INSTALLATION MANUAL - AIR SPRING CONTROL KITS, L5904

PG 3

COMPRESSOR AIR INTAKE FILTER

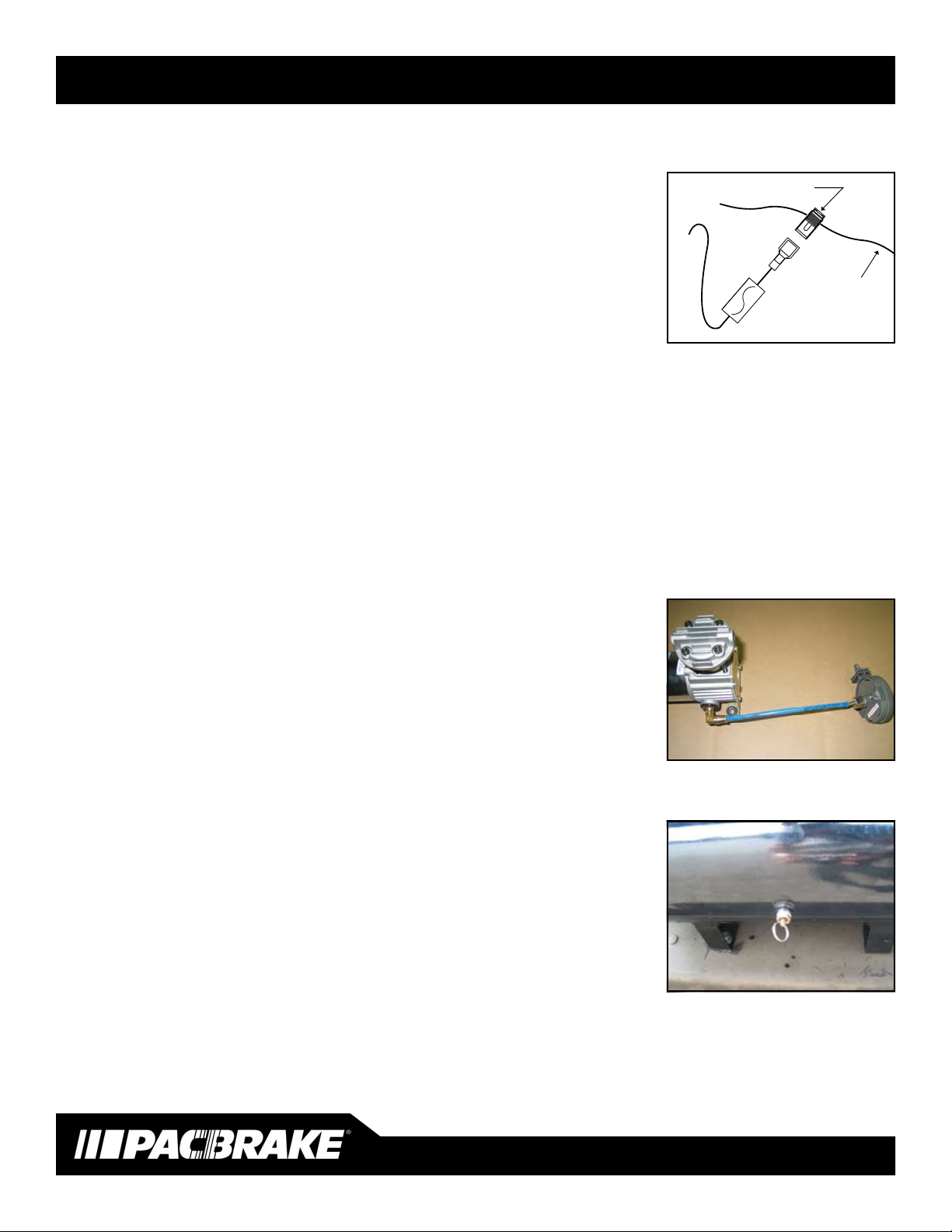

4 Locate the air intake lter housing, barbed tting and 6’ length

of blue nylon hose provided in kit. Choose a location to mount

the lter housing within 6” of the compressor, the housing re-

quires a 1/2” hole for mounting, the location must also provide

clean dry air. Secure the barbed tting to the lter housing,

connect the nylon hose to the barbed tting, install the housing

into the mounting hole. Route the nylon hose to the inlet tting at

the compressor, secure the hose with tie-straps provided.

ELECTRICAL CONNECTIONS

5 Provided in the kit is a pre-wired relay receptacle to make this

part of the installation easy. Find a convenient location close to

the positive battery terminal to mount the relay receptacle. Using

the self tapping screw provided, secure the relay receptacle and

install the relay provided.

6 Locate either one of the two red 12 gage wires of the relay

harness. Cut to length and connect the 30 amp fused link.

Connect the 30 amp fused link to the positive terminal of the

battery. Locate the second red 12 gage wire and route to the

compressor. Cut to length and crimp on the supplied blue butt

connector, then connect to the red compressor wire. Locate the

black wire of the compressor and connect to a good chassis

ground or the negative battery terminal. Heat the

connector’s to provide a water tight seal.

7 Locate the 16 gage red with white strip and the white wire of the

relay harness. Route these two wires into the cab through the

rewall boot. Connect the red with white strip wire to the 5 amp

inline fuse provided, then to a 12 volt ignition power source using

the “T” tap connector provided. Test the ignition power source

with a volt meter prior to attaching the “T” tap. Some ignition

circuits are less than 12 volts which may not be enough to acti-

vate the relay coil. This wire can be connected through an ON/

OFF switch to override the compressor activation, should the

customer prefer this option. (Switch not provided in the kit,

available separately)

Heat the butt connector’s to provide a water tight seal.

4

5

6

7

INSTALLATION MANUAL - INSERT TITLE HERE, L1234

PG 3

INSTALLATION MANUAL - PACBRAKE ONBOARD AIR SYSTEMS, L5856

PG 3

7

8

7 Locate the red 12 gauge wire of the relay harness, route

this wire to the compressor mounting location. Connect to

the red wire at the compressor. Connect the black wire of

the compressor to a good chassis ground. Using the

convoluted loom provided cover the exposed wires and

secure with tie-straps provided.

8 Install the air compressors air intake lter, using the nylon

hose marked air intake connect one end to the barbed tting

below the compressor head. Install the lter housing in the

other end of the nylon hose. Install the lter housing in a dry

clean area below the level of the air intake port to ensure

maximum compressor life.

CONNECTING AIR ACCESSORIES TO THE AIR TANK

9 Do not source air from the bottom port of the air tank. Install

the drain valve provided in the bottom port of the air tank,

periodic draining of the tank will be necessary.

NOTE: The pressure switch included in this kit has a

maximum pressure of 130 PSI and a minimum pressure

of 110 PSI, please ensure your accessories are capable of

this pressure, a regulator maybe necessary for some

accessories. Pacbrake can supply lower pressure switches

upon request. Also, Pacbrake offers dual needle gauge kits

to monitor system pressure. This gauge kit can also be used

to monitor air spring pressure.

10 Locate the quick disconnect tting provided. Consult with the

vehicle operator for their preference on the mounting

location with easy access. This location should be away

from dirt and moisture which could contaminate the tting.

Using the mounting bracket, self tapping screws, nylon air

line and ttings provided, connect it to the air tank. Use

thread sealant on all ttings installed.

9

10

PG. 3

STEP 5

5Locate the white wire of the relay harness. Connect it to an ignition power

source through the 5 amp inline fuse provided. This wire can be connected

through an ON/OFF switch to override the compressor activation should the

customer prefer this option.

6 Locate the red 12 gauge wire of the relay harness, route this wire to the

compressor mounting location. Connect to the red wire at the compressor.

Connect the black wire of the compressor to a good chassis ground. Using

the convoluted loom provided cover the exposed wires and secure with tie-

straps provided.

7 Install the air compressors air intake lter using the blue nylon hose provided.

Connect one end to the barbed tting below the compressor head. Install the

lter housing in the other end of the nylon hose. Install the lter housing in a

dry clean area below the level of the air intake port to ensure maximum com-

pressor life.

CONNECTING AIR ACCESSORIES TO THE AIR TANK

8Do not source air from the bottom port of the air tank. Install the pressure

relief valve provided in the bottom port of the air tank. Periodic draining of

the tank will be necessary.

NOTE: The pressure switch included in this kit has a maximum pressure

of 130 PSI and a minimum pressure of 110 PSI. Please ensure your

accessories are capable of this pressure - a regulator may be necessary

for some accessories. Pacbrake can supply lower pressure switches upon

request. Also, Pacbrake offers dual needle gauge kits to monitor system

pressure. This gauge kit can also be used to monitor air spring pressure.

STEP 7

STEP 8

INSTALLATION MANUAL - INSERT TITLE HERE, L1234

PG 2

INSTALLATION MANUAL - PACBRAKE ONBOARD AIR SYSTEMS, L5856

PG 2

3

4

5

3 Locate the inline air dryer provided. The dryer should be

mounted vertically between the compressor and the air

tank. The needle valve must be accessible to the operator

for periodic draining. A clamp and fastener is provided to

remote mount the air dryer if desired. Use thread sealant on

all ttings to ensure no air leaks exist.

ELECTRICAL CONNECTIONS

4 Provided in the kit is a pre-wired relay receptacle to make

this part of the installation easy. Find a convenient location

to mount the relay receptacle within 12" of the positive

battery terminal. Using the self tapping screw provided,

secure the relay receptacle and install the relay.

5 Locate the black wire of the relay harness, route it to the

air tank location. Using the ttings provided, install the pres

sure switch into one of the ports in the air tank (DO NOT

INSTALL IN THE BOTTOM PORT) Using the ttings

provided, install the pressure switch in a location for it to

sense air tank pressure. Connect the black wire of the relay

harness to one of the two wires of the pressure switch using

the heat shrink butt connector. Using the loose piece of

black wire and another heat shrink butt connector, connect

to the remaining wire of the pressure switch, heat the

connectors to provide a water tight seal. Then connect the

end with an eye terminal to a good chassis ground.

6 Locate the white wire of the relay harness. Connect it to

an ignition power source through the 5 amp inline fuse

provided. This wire can be connected through an ON/OFF

switch to over-ride the compressor activation should the

customer prefer this option.

If a HP10062 or HP10022 kit is being installed,

a compressor ON/OFF switch is included in these kits

White

5 Amp

Fuse

12v +

Ignition

Switched

14 to 16

gage wire

3M®T-tap connector