6Trip Speed Test Procedure

After following Trip Speed Programming Procedure, system must be tested to ensure Trip Speed was programmed

correctly. Entering TEST Mode causes system to trip at ‘Input Speed’ from Programming Procedure –raising engine

speed to actual ‘Trip Speed’ is unsafe and unnecessary.

Before Testing:

oIF Secondary Trip Speed Input is connected and Secondary Trip Speed has been Programmed:

Ensure power is NOT supplied Secondary Trip Speed Input before beginning Test Procedure

oIF valve is synchronized with shut-off system on same engine:

Leave all controllers connected to ensure engine shuts down

oIF valve is synchronized with shut off system on secondary engine:

Disconnect secondary controller to prevent accidental shut-down of secondary engine

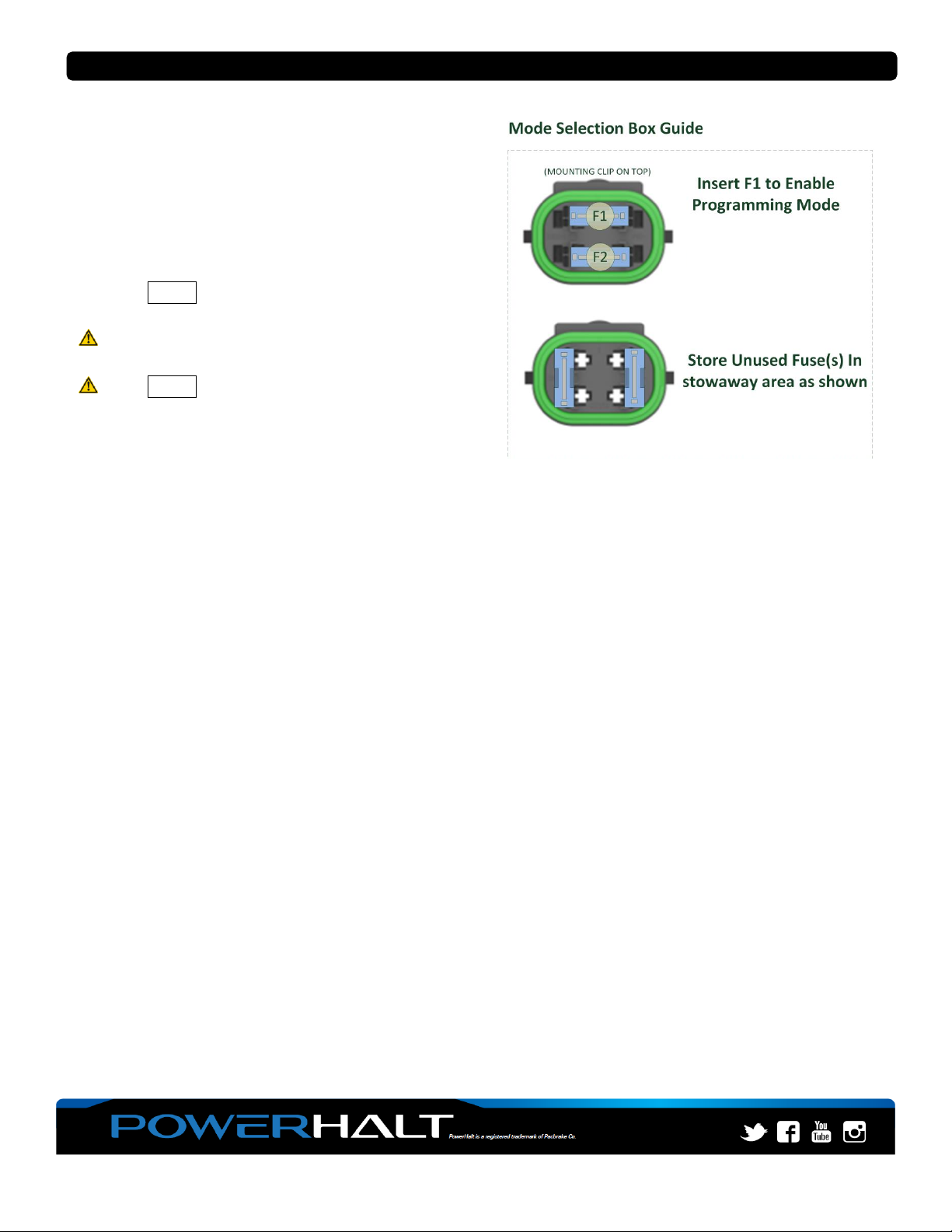

1. Ensure fuse is removed from F1 in Mode Selection Box

2. With engine off, push switch to close valve and hold switch for 5 seconds until light begins flashing rapidly

3. Release switch to re-open valve. Light will exhibit continuous rapid flash interrupted by single pulse*

4. Start engine and slowly raise engine speed to ‘Input Speed’ as previously recorded

5. Valve will close and red light will illuminate until 0 RPM is detected and 15 seconds have elapsed. When

red light extinguishes valve will be safe to re-open manually.

6. If valve did not close when expected, trip speed may not be correctly programmed. Confirm installation

and re-follow Trip Speed Programming Procedure on previous page.

Secondary Trip Speed (If applicable):

•Provide power to Secondary Trip Speed Input and repeat above procedure to test Secondary Trip Speed