PowerHalt is a registered trademark of Pacbrake Co. 7

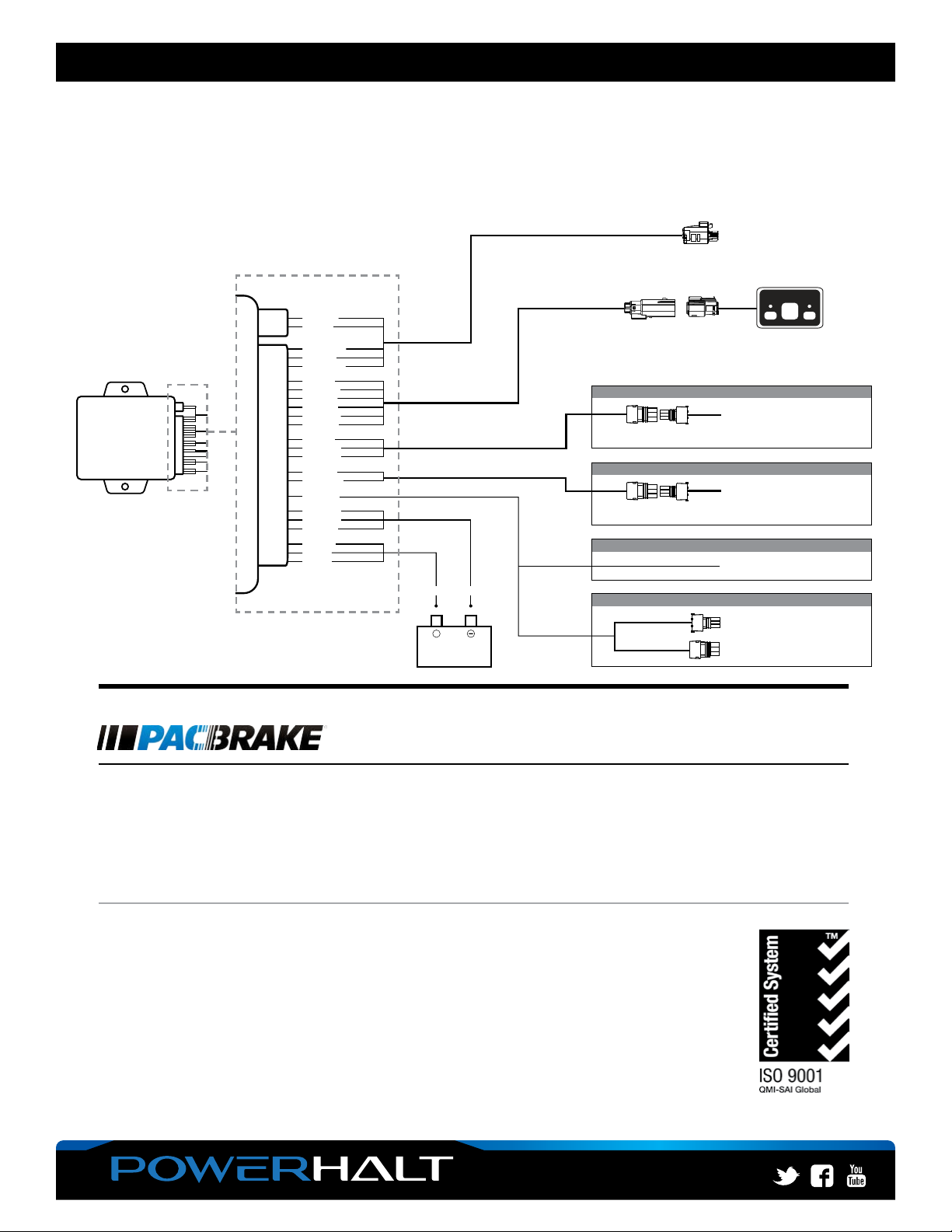

PH3 ELECTRIC + AUTOMATIC ACTUATION L6319

FLASH ERROR CODES:

1. Valve failed to close or motor position is not read

• Ensure all connectors are fully installed and latched, then cycle power

• Ifthisfails,ensurecontinuityfromthevepinconnectorattheshut-offvalvetothecontroller,

then cycle power

2. Valve failed to open or motor position is not read

• Ensure the shut-off valve connector is fully installed and latched, then cycle power

3. Valve closes too slowly or not all the way

• Inspecttheshut-offvalveforobstructions,andattempttomanuallypresstheapclosedandopen

(feeling for any binding). If the valve does not operate smoothly, contact Pacbrake support

at 800.663.0096.

4. Valve opens too slowly or not all the way

• Inspecttheshut-offvalveforobstructions,andattempttomanuallypresstheapclosedandopen

(feeling for any binding). If the valve does not operate smoothly, contact Pacbrake support

at 800.663.0096.

5. Shut-off valve pulls too much current

• Ensurecontinuityfromtheve-pinconnectorattheshut-offvalvetothecontrolleronthetwolarge

power wires (red and black). Check for damage to the wires causing shorts, then cycle power.

6-9. Internal controller error

• Contact Pacbrake support at 800.663.0096

7POWERGUARD SET-UP & TEST PROCEDURE

TO SETUP RPM:

With the engine running, hold the reset and test buttons together for 5 seconds until both led lights start

ashing,andthenreleasebothbuttons

The controller is now in the set/test mode with 3 options (see below)

FIRST: Ifyourcontrollerisalreadysetforaspecic rpm, and you want to change the rpm trip point, press

and hold reset for 5 seconds to remove the rpm limit, then the controller will revert to Functional State 1

(from step 6)

SECOND: If your controller has not been set up, pressing and releasing the RESET button will set the trip

point based on number of presses, as described below

1. Press 1x = Creates a trip point at 10% over the current rpm

2. Press 2x = Creates a trip point at 20% over the current rpm

3. Press 3x = Creates a trip point at 30% over the current rpm

4. Press 4x = Creates a trip point at double the current rpm

There must be less than 2 seconds between presses

After presses are complete, the red ledwillashcorrespondingtothenumberofpressesdetectedfor

conrmationofnewtrippoint

If there was no RPM detected when pressing the RESET button, the controller will remove the existing

RPM trip point and change to Functional State 1 (from step 6)

If no action is taken while in the set/test mode, after 60 seconds the controller will timeout and return to

normal function.