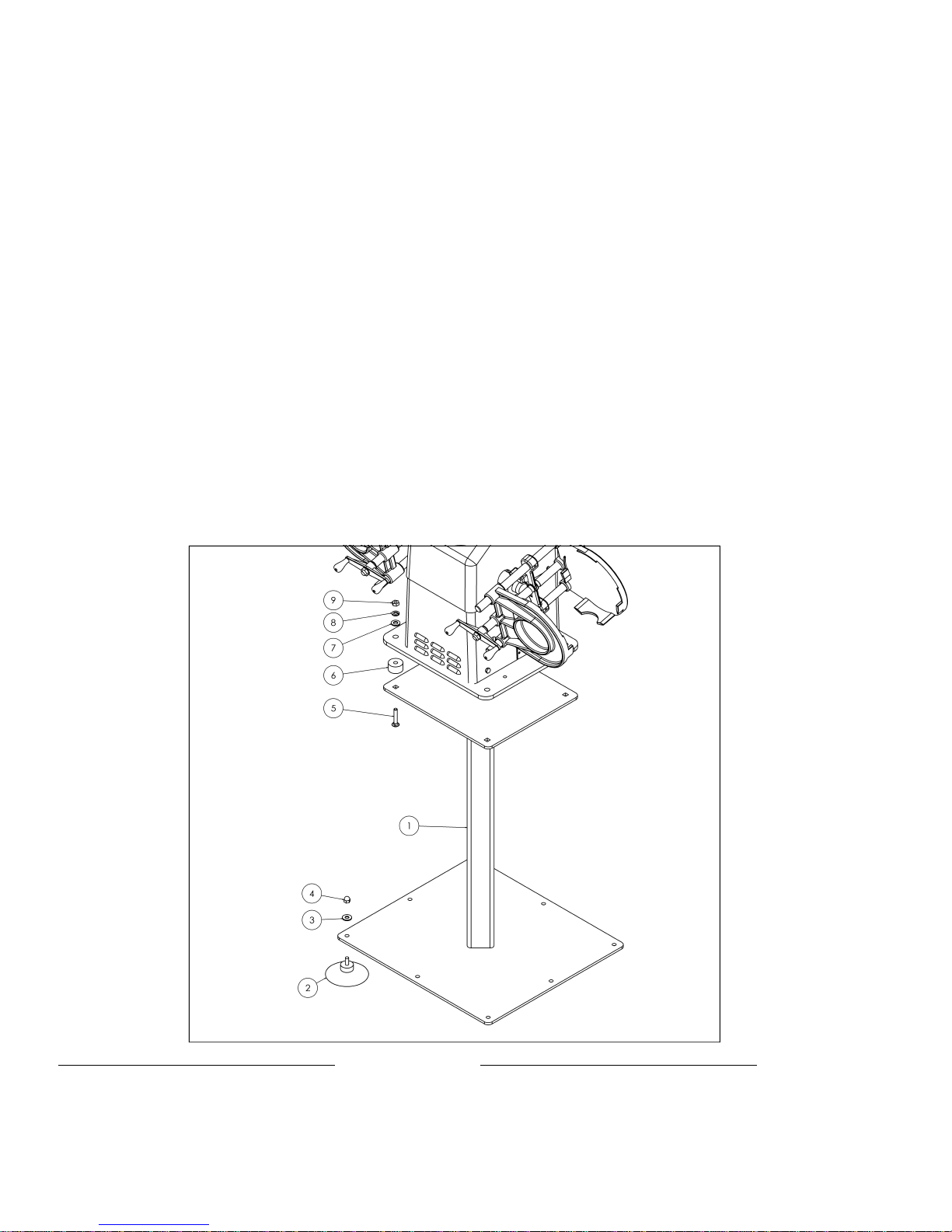

Installing the mixer on the Floor Stand.

1. Assemble (8) suction cups to the bottom of the floor stand using the hardware provided.

2. Assemble the mixer and (4) isolators (provided with the mixer) to the Floor Stand using the hardware pro-

vided.

3. Plug the power cord into a grounded receptacle (see page 7).

Note: Explosion proof models are not furnished with a power cord. The machine must be hard wired to

the power source by a qualified electrician.

4. If the suction cups do not grip the floor properly the base may creep while the mixer is operating. If this

does occur, anchor the base to the floor with rubber cement:

A. Tilt the mixer and floor stand until you can fit two 2” x 4” boards under the floor stand. This will lift

the suction cups far enough off the floor to apply rubber cement. Make sure the boards do not touch the

suction cups.

B. Clean the floor directly under the suction cups. Clean the contacting surface of the suction cups.

C. Apply rubber cement to the contacting surface of the suction cups and the floor directly under the suc-

tion cups.

D. Allow the rubber cement to dry until it becomes tacky. Remove the boards and lower the floor stand to

the floor.

E. Allow the rubber cement to dry overnight before running the mixer.

If you ever need to move the mixer, you can break the bond by inserting a wall scraper between the suction cup

and the floor.

Item Qty. Part Number / Description

1 1 PIM-10108 Floor stand

2 8 PIM-10069 Suction cup

3 8 PIM-10120 Flat washer, 5/16

4 8 PIM-10126 Acorn nut, 5/16-18

5 4 PIM-10115 Carriage bolt, 3/8-16 x 2.50

Item Qty. Part Number / Description

6 4 PIM-10049 Isolator

7 4 PIM-10119 Flat washer, 3/8

8 4 PIM-10172 Lock washer, split 3/8

9 4 PIM-10127 Nut, hex 3/8-16

6