2

CONTENTS

Safety-Important ......................................................................................................................... 1

1.Foreword .................................................................................................................................... 3

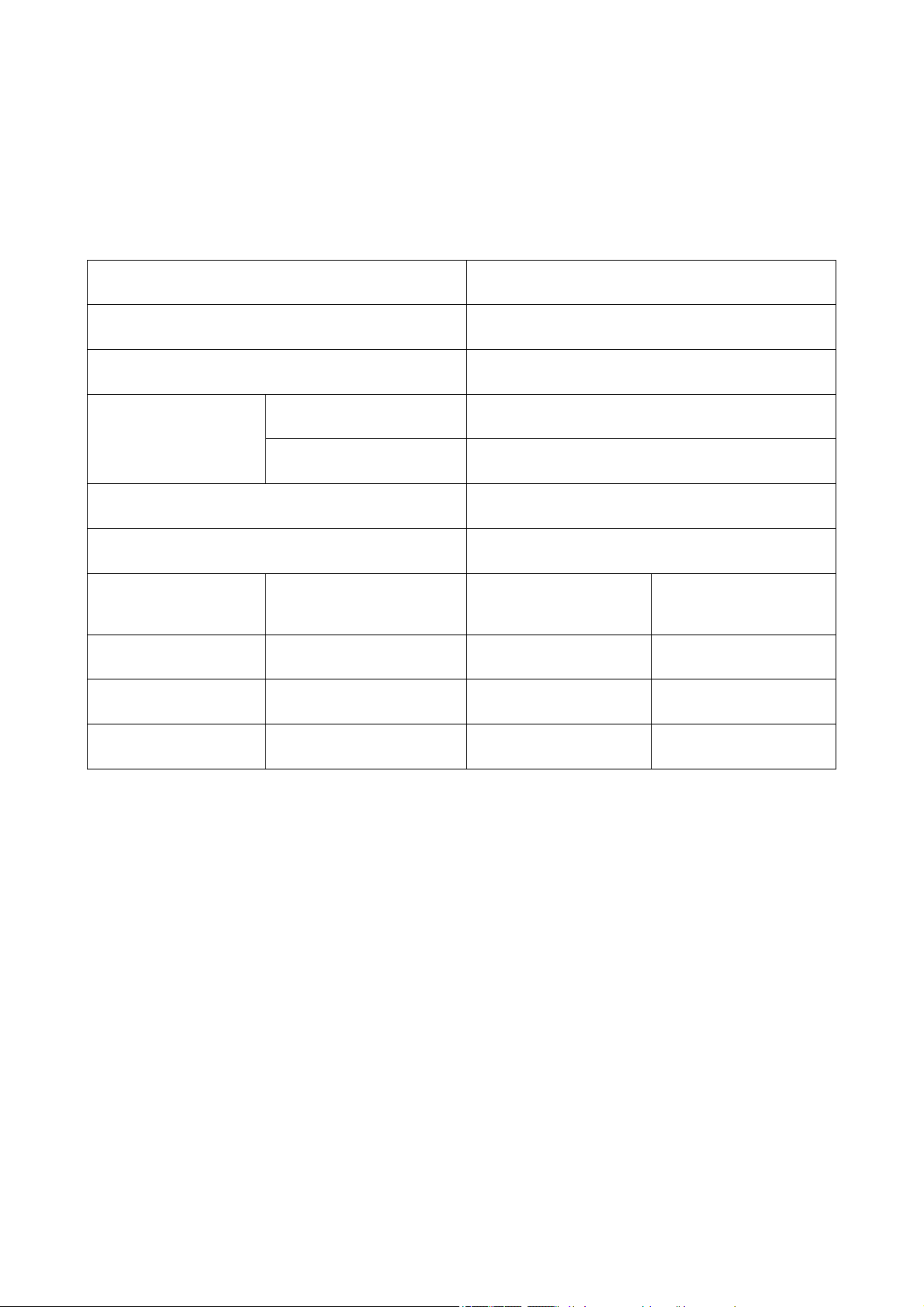

2.Main Specification .................................................................................................................... 4

2.1 Specification ........................................................................................................................... 4

2.2 Mechanical Classification (Grade) and Life ....................................................................... 5

2.3 Safety Device .......................................................................................................................... 6

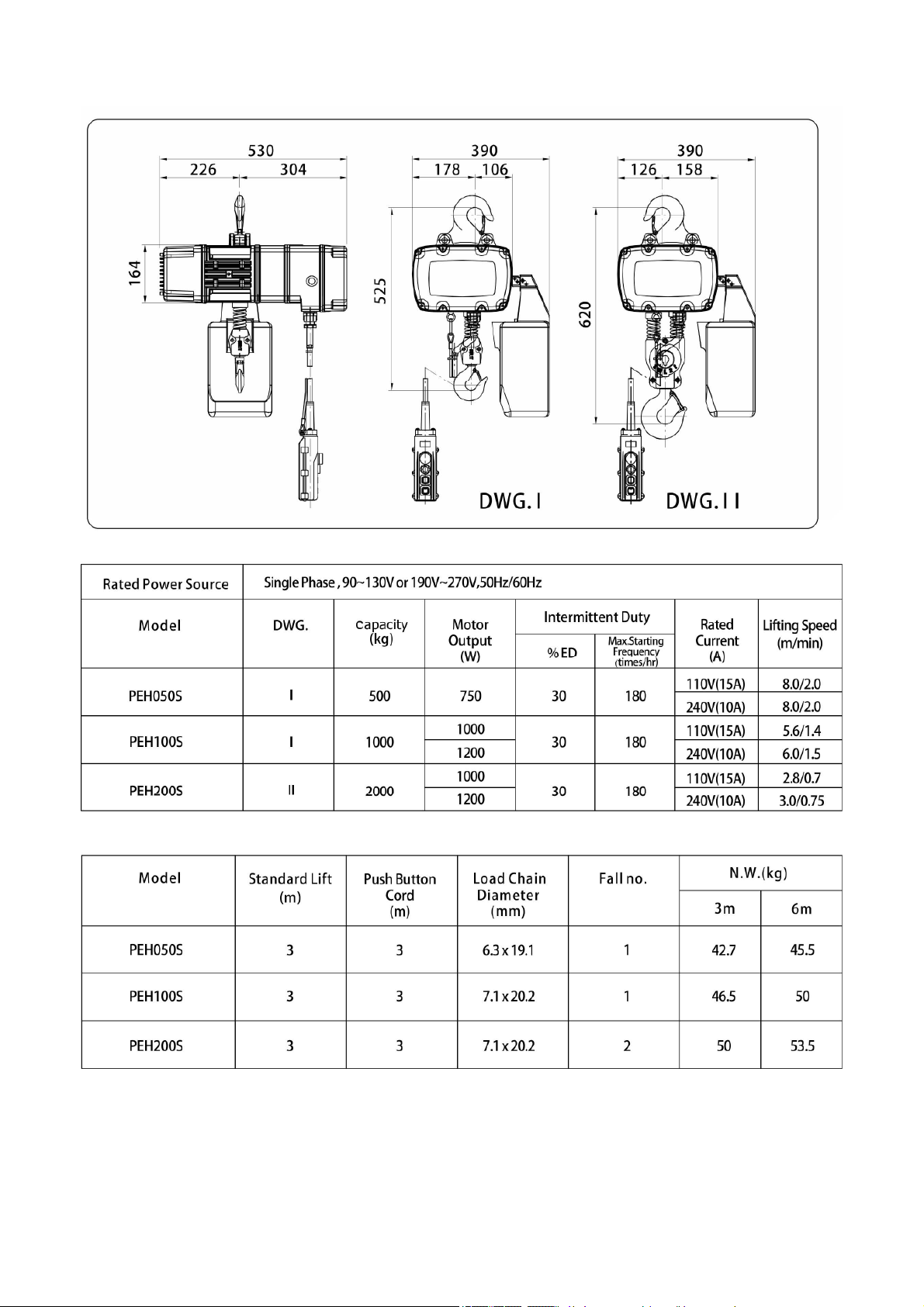

2.4 Specification and Dimensions ............................................................................................. 7

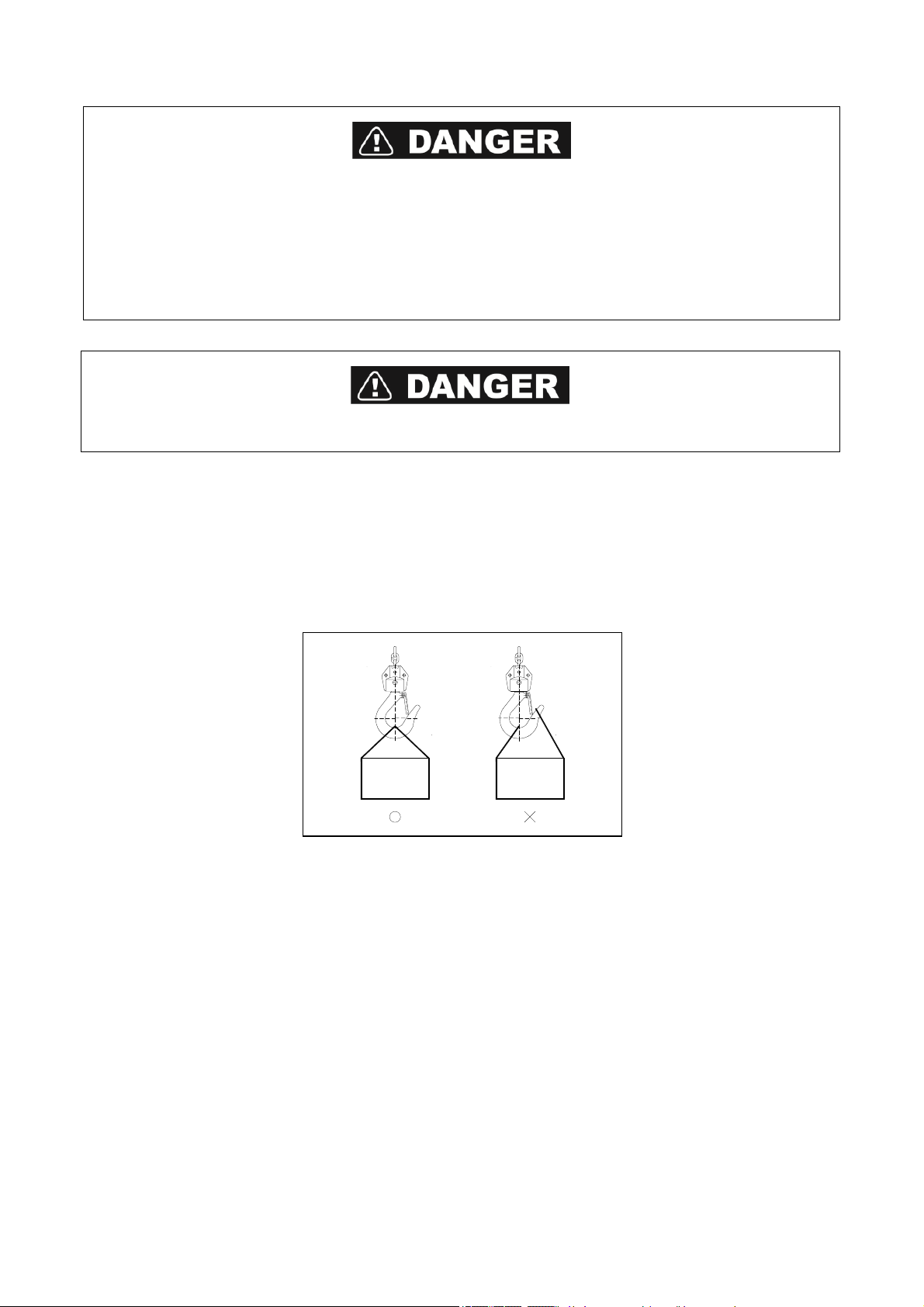

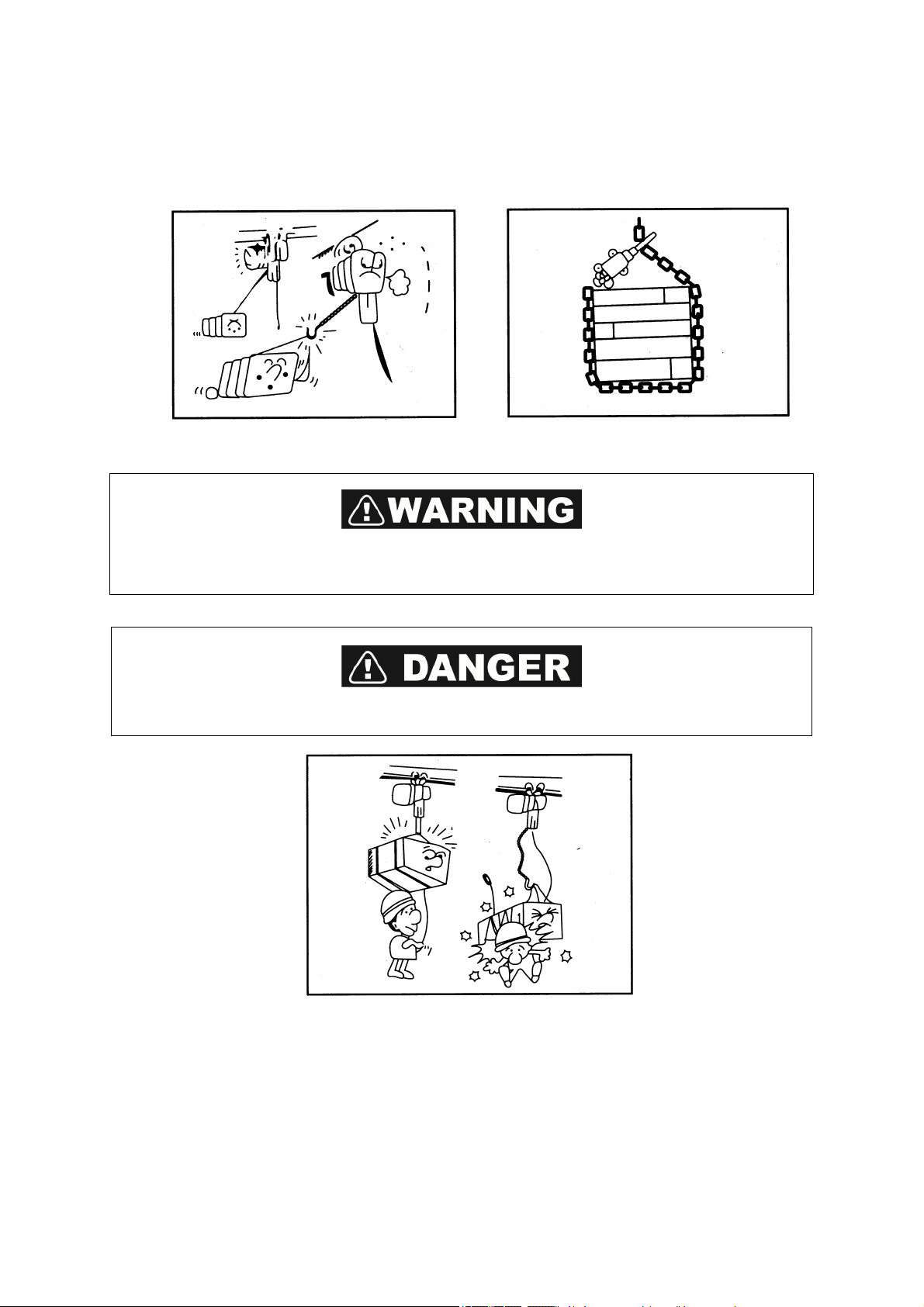

3.Safety Rules ............................................................................................................................... 8

4.Installation ............................................................................................................................... 10

4.1 Unpacking Information ...................................................................................................... 10

4.2 Voltage .................................................................................................................................. 10

4.3 Installation ............................................................................................................................ 11

5.Operation ................................................................................................................................. 12

6.Maintenance and Inspection ................................................................................................ 13

6.1 Maintenance ......................................................................................................................... 13

6.2 Inspection ............................................................................................................................. 13

7.Troubleshooting ..................................................................................................................... 16

7.1 Wiring Diagrams .................................................................................................................. 16

7.2 Troubleshooting and Remedial Action ........................................................................... 18

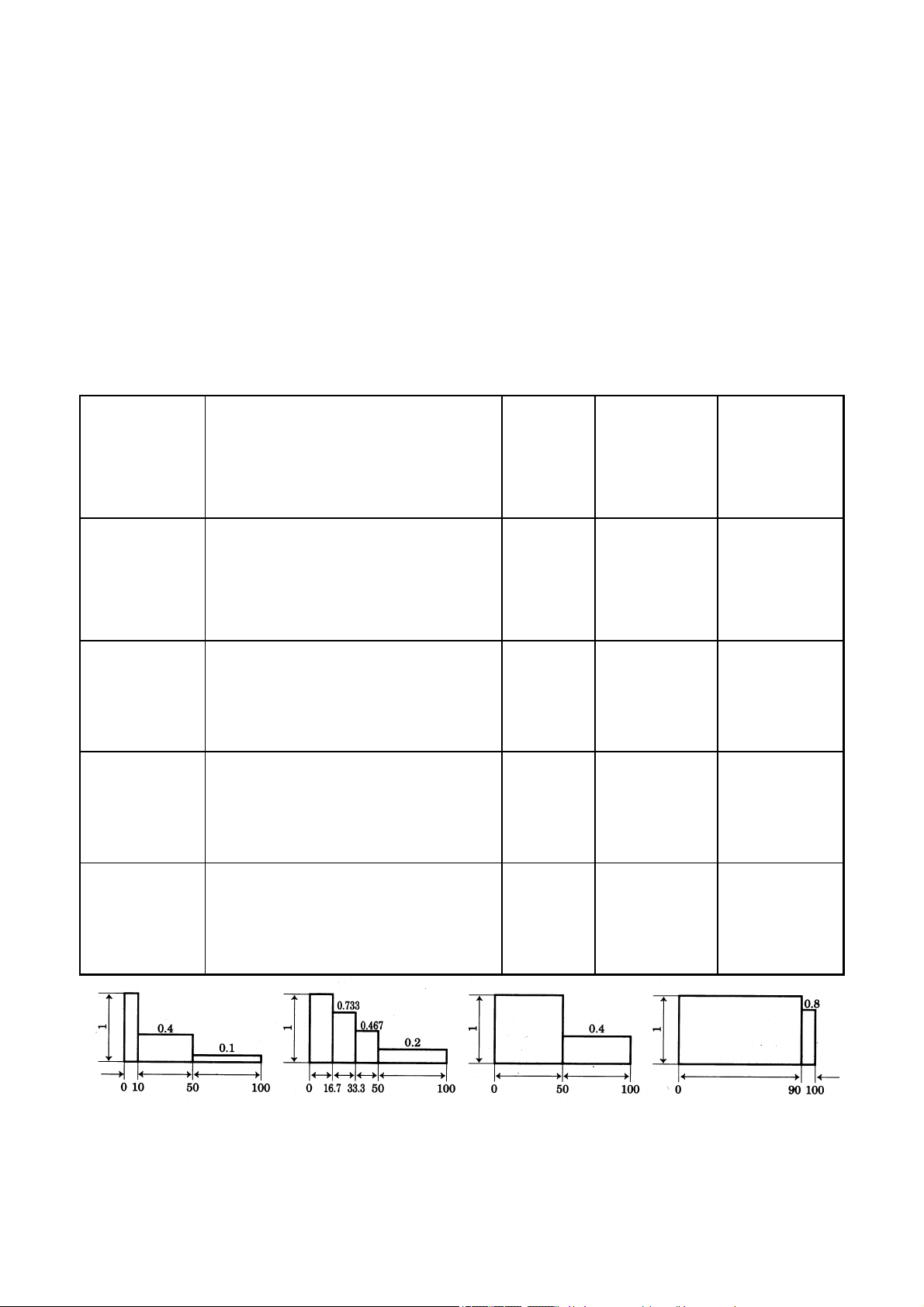

7.3 Overload clutch adjustment instruction ......................................................................... 19

8.Drawings and Parts ................................................................................................................ 20

9.Declaration Of Conformity .................................................................................................... 32