- 3 -

Title Page

Label Lead Fixed Assembly ........................................................................................................................... 43

Label Lead Assembly 2 ................................................................................................................................. 44

Label Lead Assembly 3 ................................................................................................................................. 45

Brush Set ...................................................................................................................................................... 46

Label Peel Plate Assembly ............................................................................................................................ 47

PU Roller Assembly ...................................................................................................................................... 48

Lever Sleeve Assembly ................................................................................................................................. 49

Base Paper Collect Assembly 1 .................................................................................................................... 50

Base Paper Collect Assembly 2 .................................................................................................................... 51

Applicator Motor Assembly ......................................................................................................................... 52

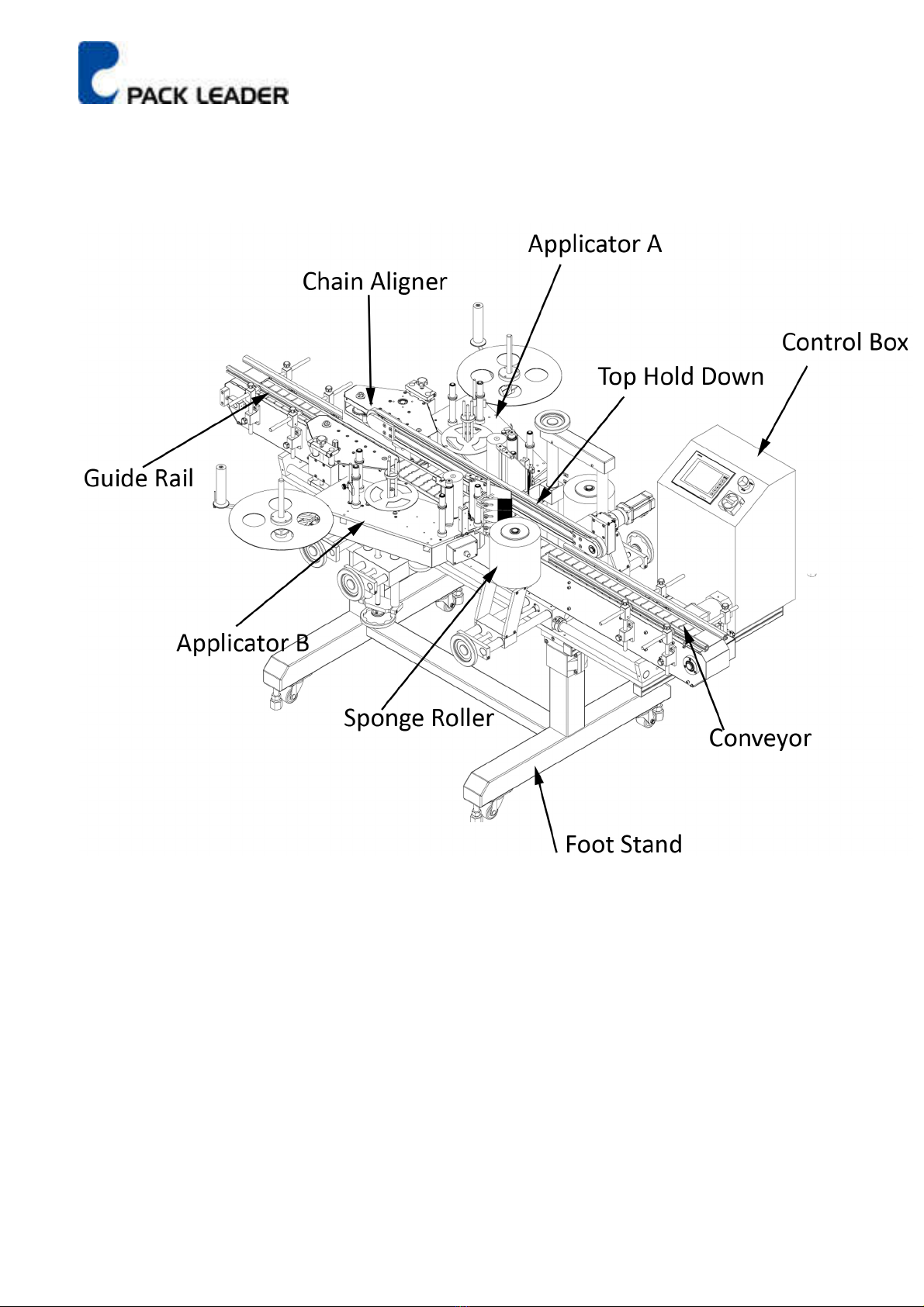

Applicator Adjustment -1 ............................................................................................................................. 53

Applicator Adjustment -2 ............................................................................................................................. 54

Applicator Adjustment -3 ............................................................................................................................. 55

Chain Ali ner Adjustment Assembly ............................................................................................................ 56

Chain Ali ner F/B Adjustment Assembly ..................................................................................................... 57

Chain Ali ner Motor Assembly .................................................................................................................... 58

Bevel Gear Base Set-1 .................................................................................................................................. 59

Bevel Gear Base Set-2 .................................................................................................................................. 60

Chain Ali ner Assembly – 1 .......................................................................................................................... 61

Chain Ali ner Assembly – 2 .......................................................................................................................... 63

Chain Ali ner Assembly – 2 Part List ............................................................................................................ 64

Chain Roller Set ............................................................................................................................................ 65

Chain Roller Base Set ................................................................................................................................... 66

Elasticity Plate Set ........................................................................................................................................ 67

Driven Chain Roller Set -1 ............................................................................................................................ 68

Driven Chain Roller Set -2 ............................................................................................................................ 69

Chain Ali ner Slidin Base ............................................................................................................................ 70

Top Hold Down Adjustment Assembly ......................................................................................................... 71

Top Hold Down Adjustment Assembly Part List ........................................................................................... 72

Top Hold Down A .......................................................................................................................................... 73

Top Hold Down Roller Assembly .................................................................................................................. 74

Top Hold Down Driven Plate Assembly ........................................................................................................ 75

Top Hold Down Driven Pulley Assembly ...................................................................................................... 76

Top Hold Down Drivin Pulley Assembly ..................................................................................................... 78