- 1 -

Table of Contents

Title Page

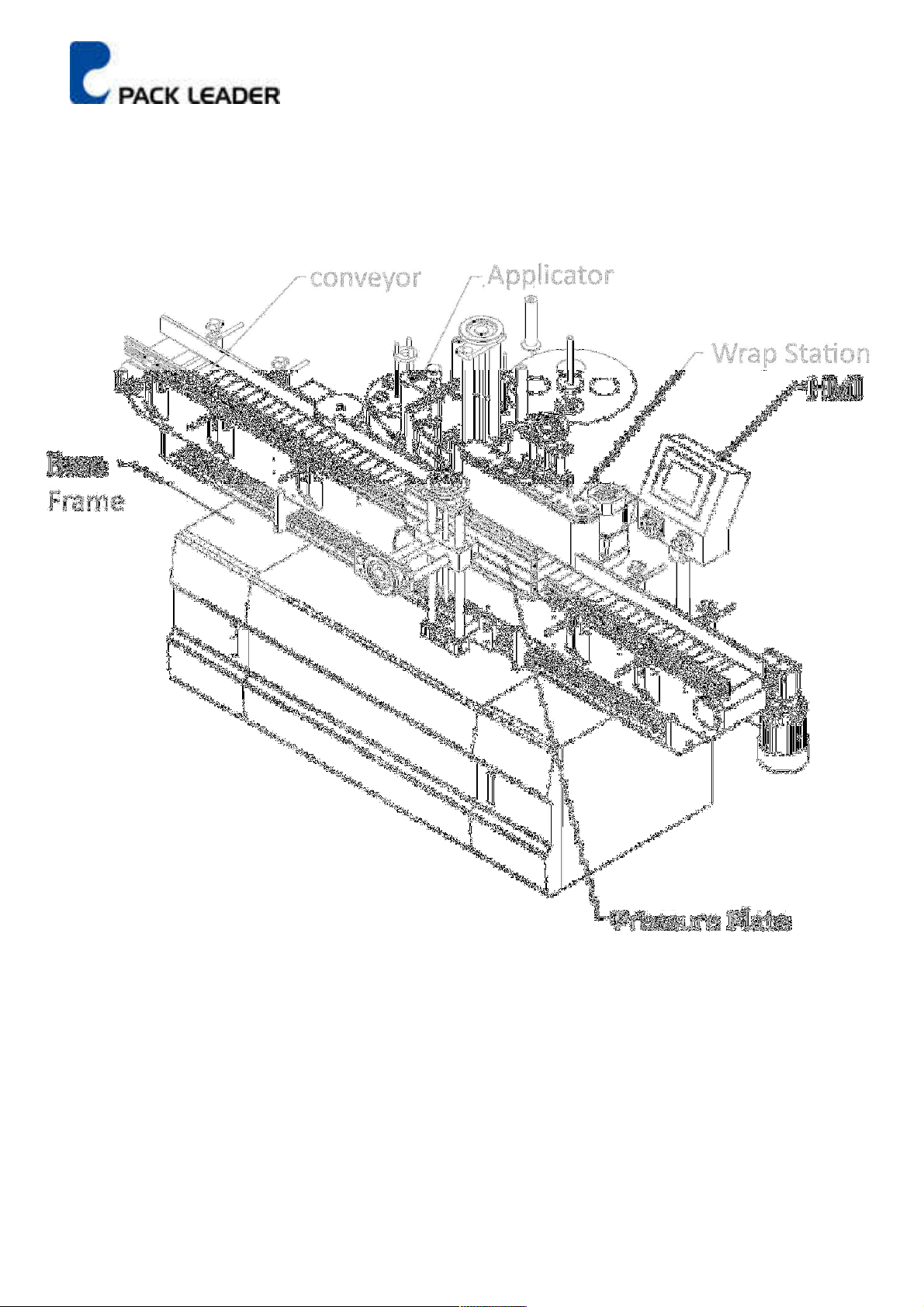

Machine Sub- Assemblies ........................................................................................................................... 3

Machine Dimensions................................................................................................................................... 4

Machine Specification ................................................................................................................................. 5

Machine Features........................................................................................................................................ 6

Specification of Label Reel .......................................................................................................................... 7

Safet Regulations ....................................................................................................................................... 8

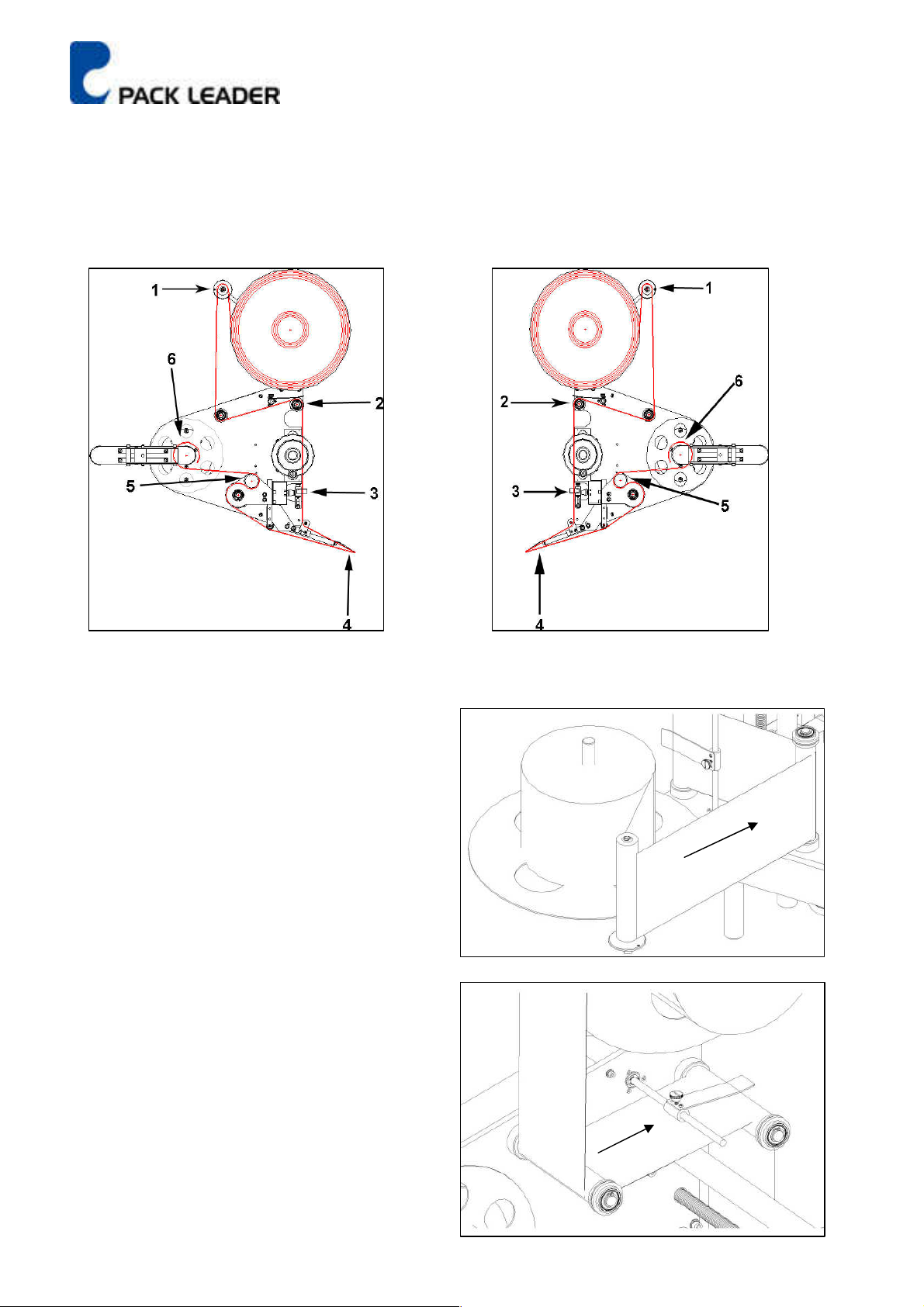

Label Applicator .......................................................................................................................................... 9

Guide Rail .................................................................................................................................................. 12

Position of Object Sensor .......................................................................................................................... 14

Parts Adjustments ..................................................................................................................................... 15

Label Sensor Position ................................................................................................................................ 18

Machine Operation ................................................................................................................................... 19

Touch Screen ............................................................................................................................................. 23

Trouble Shooting ....................................................................................................................................... 24

Electronic Diagram .................................................................................................................................... 26

HMI Frame ................................................................................................................................................ 27

Control Box Frame .................................................................................................................................... 28

Control Box Frame .................................................................................................................................... 29

Electronic Parts List ................................................................................................................................... 30

Applicator Exploded View ......................................................................................................................... 31

Applicator Exploded Part List .................................................................................................................... 32

Label Suppl Plate Assembl ..................................................................................................................... 33

Label Suppl Plate Assembl Part List ....................................................................................................... 34

Tension Bar Assembl ............................................................................................................................... 35

Applicator Motor Assembl ...................................................................................................................... 36

Base Paper Collect Driven Pulle Set ........................................................................................................ 37

Base Paper Collect Assembl .................................................................................................................... 38

Base Paper Collect Assembl Part List ...................................................................................................... 39

Label Lead Assembl 1 .............................................................................................................................. 40

Label Press Assembl ................................................................................................................................ 41

Label Lead Assembl 2 .............................................................................................................................. 42

Lever Sleeve Assembl .............................................................................................................................. 43

PU Roller Assembl ................................................................................................................................... 44

PU Roller Assembl Part List ..................................................................................................................... 45