:-;,

JP4`

(^,

(+``

In a similar manner mount black pin jack J3.

In a similar manner mount red pin jack J4.

In a similar manner mount red pin jack J5.

In a similar manner mount red pin jack J6.

In a similar manner mount red pin jack J7.

One Light Emitting Diode remains to be mounted on the ''8" board. Just to the right of

the circuit board point "WW" are two holes marked ''LED" (left side of board). Solder

two of the ''flea clips" provided into these holes. Note that when properly installed the

upright portions of the "U" shape of this clip will be pointed toward the closest edge Of

the circuit board. (see figure 9)

(q# Install the two LED supporting flea clips.

Bend the leads of the LED ±gg±±!y back and slip them into the clips such that they are roughly

parallel with the surface Of the circuit board. The ends Of the LED should be even with the rear

edges Of the clips. Make sure that the unmarked lead goes into the clip that Connects to R6o.

Lightly solder the LED leads to the clips.

Placethefrontpanelface\downonasoftragtopreventmarringthefinish.

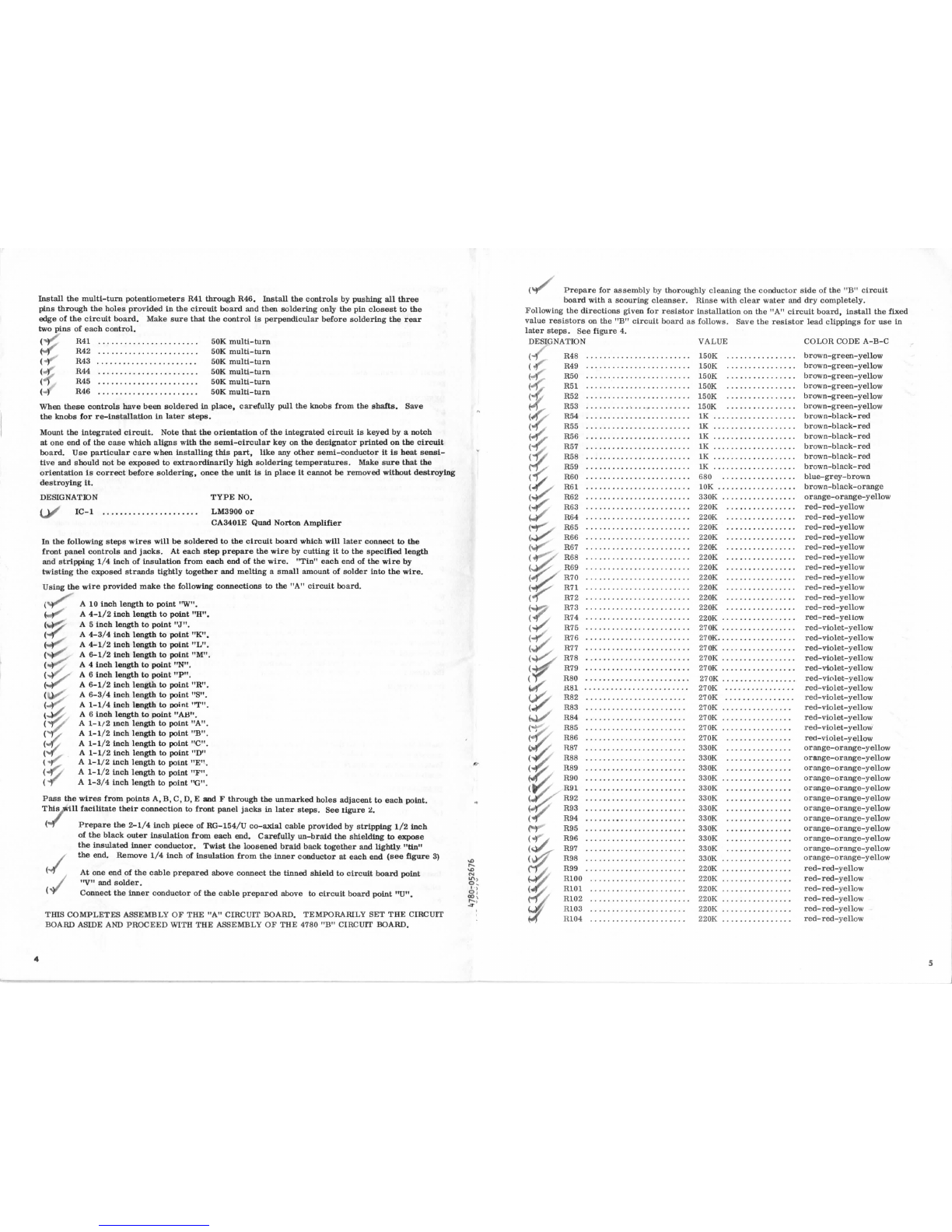

ae`' Place a blackpin jack (J1) in thehole provided as shown in figure 10. Fasten in

place with a tinnerman nut as shown in figure 11. Press the tinnerman out down firmly.

NOTE that all tinnerman nuts must be mounted verticly as shown in figure 10.

faS Ina Similar manner mount black pinjack (J2) as shownin figure lo.

'£' -_ -.=_&`__ ___

(`y¢ In a similarmanner mount red pin jackJ8.

In a similar manner mount red pin jack J9.

In a similar manner mount red pin jack J10.

(-`) In a similar manner mou[it red pin jack Jll.

(/t In a Similar manner mount red pin jack J12.

(|`' In a similar manner mount red pin jackJ13.

(|`'' In a similarmanner mount red pin jackJ14.

(rf h a Similar manner mount red pin jack J15.

(-i ln a similar manner mount red pin jack J16.

:f//,

In a similar manner mount red pin jack J17.

In a similar manner mount red pin jack J18.

¢}p/ Using two 440 X 1/4 inch screws. two 4-40 nuts and two lock nuts, mount slide switeh s1

„.,

in the position shown ln figure 10. Make sure that the points Of the 4-40 nuts do not interfere

with the travel of the slide inside the Switch.

Mount the SPST push button switoh S2 in the position shown in figure 10. Use the lockwasher

between the rear surface Of the front panel and the body of the switoh.

In a similar manner mount pushbutton switch S3.

Mount 500K potentiometer R135 in the location shown in figure 10. Use two 3/8 inch nuts,

one behind the front panel as a spacer and the second on the front side Of the panel to secure

the potentiometer. Adjust the rear nut so that none Of the threaded shaft Of the control is

exposed when the front nut is tightened down. This will allow the control knob which will be

mounted in a later step to seat as closely as possible to the front panel. Orieut as illustrated.

(a;# In a similar manner mount 500K potentlometer R136 in the location shown in figure 10.

rfu<.L# orient as illustrated,

In a similar manner mount 75K potentiometer R137. Orient as illustrated.

In the following steps interconnection wiring will be done on the front panel controls. At each step

cut the wire to the specified length and strip 1/4 inch of insulation from each end. Twist the exposed

strands and tin by melting a small amount of solder into the wire. (Bee figure 12)

110

(.i..

HE]

Prepare a 1-1/2 inch length Of insulated wire and connect lug #2 o£ Sl and lug #3 of R135.

Solder the connection at Sl but do not solder the connection at R135 at this time.

Cut one lead of loon resistor R139 (brown-black-yellow) to a length of 1/2 inch and the

other lead to a length o£ 1 inch.

(rty D"" Pass the 1 inch lead of the previously prepared resistor through lug #3 of R137 to lug #2 Of

R137. Pass the 1/2 inch lend of this resistor through lug #1 of R137. Solder the connection

at lug #2 of R137 but do not solder the connections at lug #1 and lug #3 at this time.

(ri}. Cut both leads of 4. 7K resistor R138 tyellow-violet-red) to a length of 3/8 inch.

( +)Y Connect one lead of the previously prepared resistor to lug #1 of R136 and the other lead

to lug #3 of R136. Do not solder either connection.

S:¢bys'"' Prepare a 2 inch lengthofinsulatedwire and connect lug#1 ofs2 to lug#2 ofs3. Solder

the connection at S3 but do not solder the connection at S2 at this t`ime.

(+'~ :arcehp:::d: ]g:£]p4t::°:eeags5 obfyt::Sds££ondgeaof¥:/{4nc:c]henbgetyho:: tthhee pe`nadst;: tthuebttnugb£Pnrg:V[ded over

(dy~-' Connect the lead coming from the end of D5 that is marked with a colored band to lug #1

of S3. NOTE: Correct orientation of this diode is necessary for operation of the unit.

Solder this connection.

Connect the remaining lead of D5 to J1. DO NOT Sol.DER.

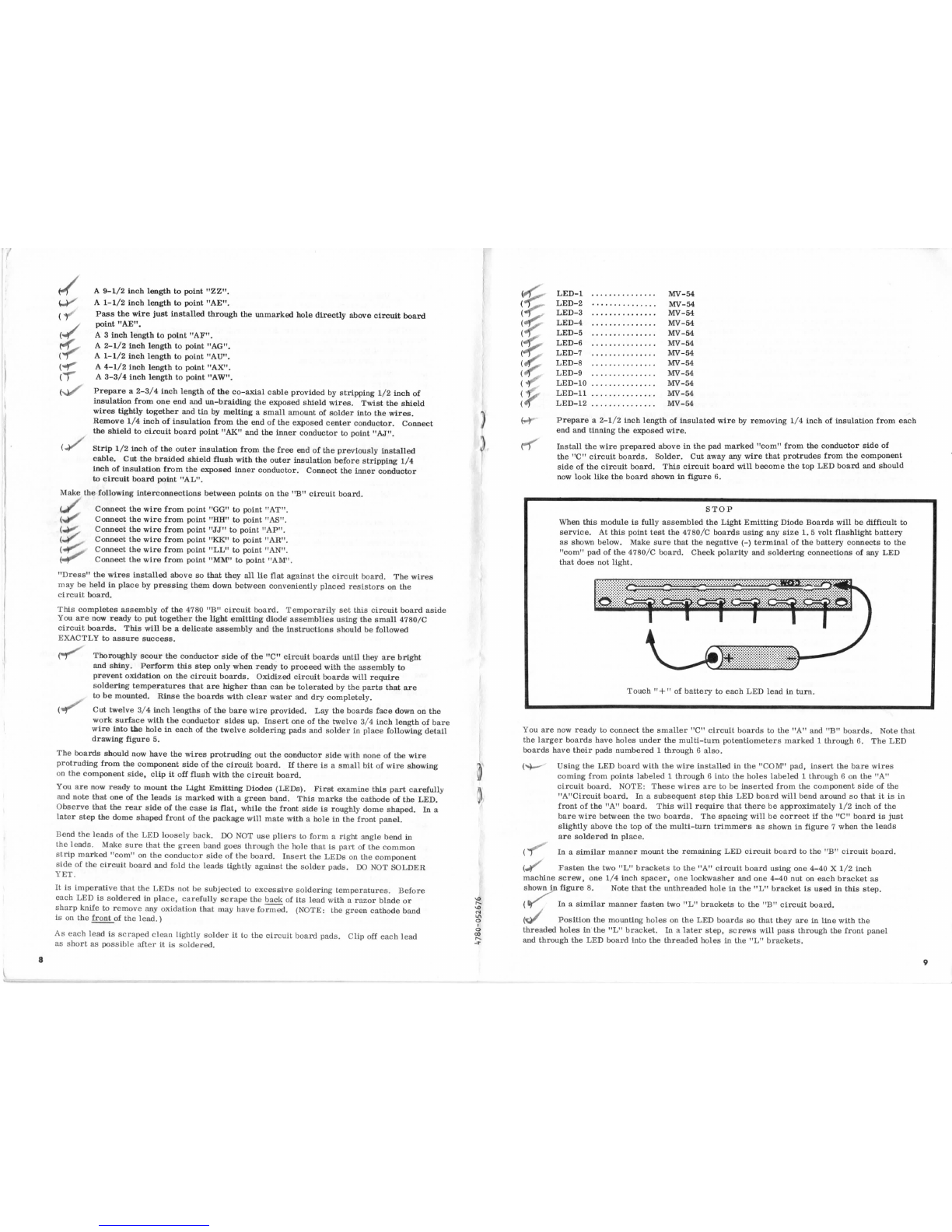

Peel the cardboard backing from the black ''dots" provided. Mount the dots over the LED

holes on the back of the front panel as shown in detail figure 10.

THE CIRCUIT BOARDS MAY NOW BE BOLTED TO THE FRONT PANEL AS FOLLOWS:

/

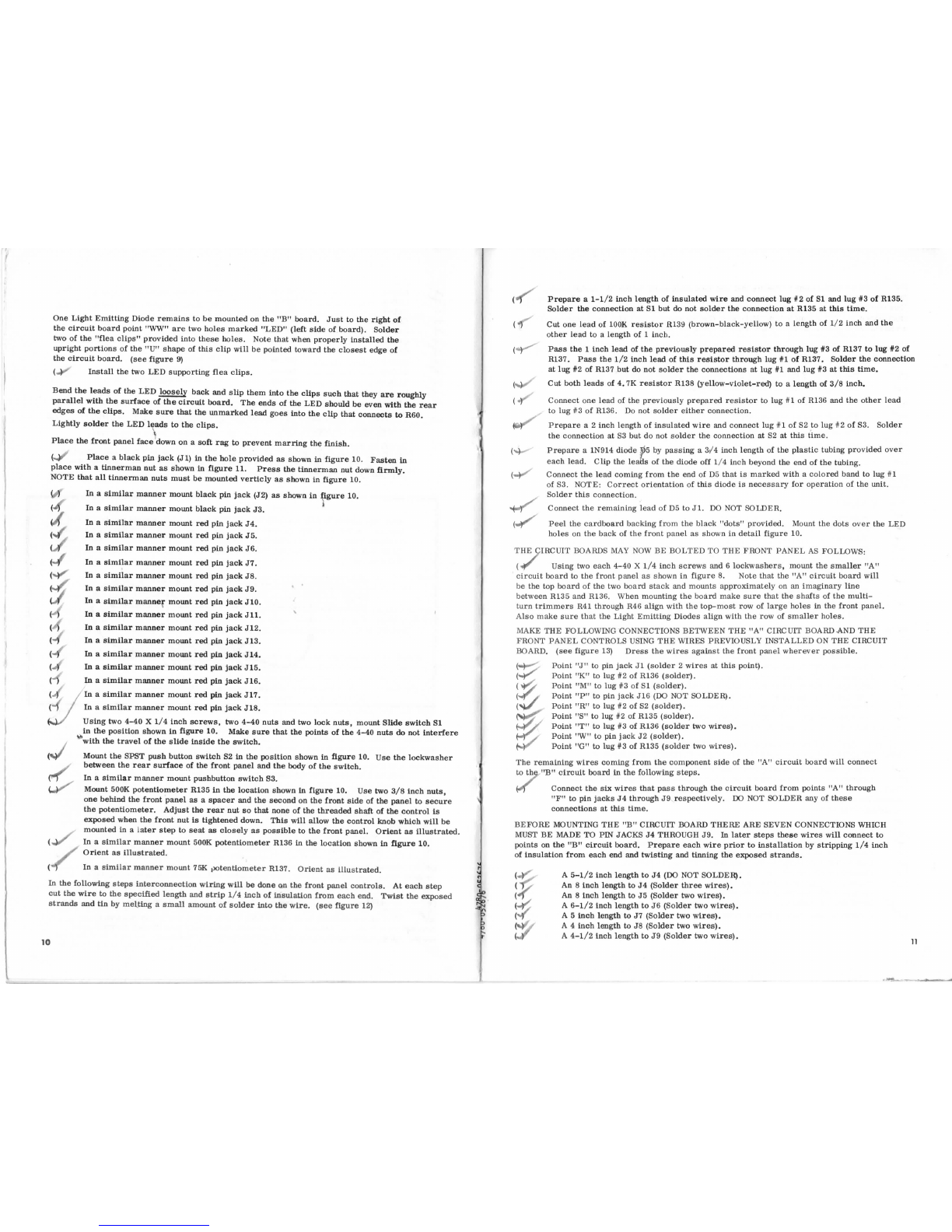

Using two each 4-40 X 1/4 inch screws and 61ockwashers, mount the smaller ''A"

circuit board to the front panel as shown in figure 8. Note that the ''A" circuit board will

be the top board of the two board stack and mounts approximately on an imaginary line

between R135 and R136. When mounting the board make sure that the shafts of the multi-

turn trimmers R41 through R46 align with the top-most row of large holes in the front panel.

Also make sure that the Light Emitting Diodes align with the row of smaller holes.

MAKE THE FOLLOWING CONNECTIONS BETWEEN THE ''A" CIRCUIT BOARD.AND THE

FRONT PANEL CONTROLS USING THE WIRES PREVIOUSLY INSTALLED ON THE CIRCUIT

BOARD. (see figure 13) Dress the wires against the front panel wherever possible.

rl-

Point ''J" to pin jack J1 (solder 2 wires at this point).

Point ''K" to lug #2 of R136 (solder).

Point "M" to lug #3 of S1 (solder).

Point ''P" to pin jack J16 (DO NOT SOLDER) .

Point ''R" to lug #2 of S2 (solder).

Point ''S" to lug #2 of R135 (solder).

Point ''T" to lug #3 of R136 (solder two wires).

Point ''W" to pin jack J2 (solder).

Point ''G" to lug #3 of R135 (solder two wires).

The remaining wires coming from the component side of the "A" circuit board will connect

to thg, ''8" circuit board in the following steps.

Connect the six wires that pass through the circuit board from points ''A" through

''F" to pin jacks J4 through J9 respectively. ro NOT SOLDER any of these

connections at this time.

BEFORE MOUNTING THE ''8'' CIRCUIT BOARD THERE ARE SEVEN CONNECTIONS WIIICH

MUST BE MADE TO PIN JACKS J4 THROUGH J9. h later steps these wires will connect to

points on the ''8" circuit board. Prepare each wire prior to installation by stripping 1/4 inch

Of insulation from each end and twisting and tinning the exposed strands.

A 5-1/2 inch length to J4 (DO NOT SOLDEI9

An 8 inch length to J4 (Solder three wires).

An 8 inch length to J5 (Solder two wires).

A 6-1/2 inch length to J6 (Solder two wires).

A 5 inch length to J7 (Solder two wires).

A 4 inch length to J8 (Solder two wires).

A 4-1/2 inch length to J9 (Solder two wires).