Section 150-319-254

Revision 02

Page 3

TABLE 1. HDSL CABLE LOSS

Cable Gauge Loss @ 260

kHz(db/km) Ohms per km

26/0.4 mm 13.94 272

24/0.51 mm 10.47 171

22/0.61 mm 8.14 105

19/0.91 mm 5.74 52

TABLE 2. HIGAIN E1 RANGES (KM) ON

UNIMPAIRED CABLES VS AVERAGE

MARGIN(M) IN DB

Cable Gauge M = 11 M = 7 M = 3

0.4 mm / #26 AWG 2.7 km 3.0 km 3.3 km

0.51 mm / #24

AWG 3.6 km 4.0 km 4.4 km

0.61 mm / #22

AWG 4.7 km 5.2 km 5.7 km

0.81 mm / #19

AWG 6.6 km 7.3 km 8.0 km

2. APPLICATIONS

2.01 The HiGain System provides a cost-

effective, easy-to-deploy method for

delivering G.703 High Capacity Digital Service

(HCDS) over metallic pairs. The fiber-like quality

service is deployed over two unconditioned, non-

loaded copper pairs. Conventional span repeaters

are not required. Cable pair conditioning, pair

separation and bridged tap removal, are also not

required.

2.02 The HiGain system operates with any

number of other G.703, Plain Old Telephone

System (POTS), digital or analog data service or

other HiGain Systems sharing the same cable

binder group. HiGain provides a means of quickly

deploying service in advance of fiber-optic

transmission systems. By using HiGain G.703, you

can connect service within a few days or even a few

hours. You can install fiber optic systems at a

leisurely pace and cut-over from HiGain when the

time allows. You can then easily remove the HiGain

and utilize it elsewhere.

2.03 Table 1 provides a guide for the loss of

various cable gauges at the HDSL line rate

of 260 kHz and 135 ohms. The table applies to the

HDSL cable pairs between the ELU and the EDU-

451 as well as between the EDU-451 and a second

EDU-451 or the ERU-412. Add 3 dB for each

bridged tap and 1 dB for each cable gauge change.

2.04 The ELU to ERU operating ranges, on

unimpaired cable pairs, are shown in Table

2 as a function of cable gauge and average margin.

2.05 The ELU-319, List 5D and 6D line units

support both one and two doubler

applications. For two doubler applications the ERU

must be locally powered. For one doubler

applications both the EDU and ERU can be line

powered.

3. FUNCTIONAL OPERATION

3.01 HiGain utilizes PairGain's 2-Bits-1-

Quaternary (2B1Q) HDSL transceiver

systems to establish two full-duplex 1040 Kbps data

channels between the ELU-319 and an ERU-412

HiGain Remote Unit or EDU-451 doubler unit. This

provides a total capacity of 2.080 Mbps between the

two units: 2.048 Mbps for the G.703 interface and 32

Kbps of overhead.

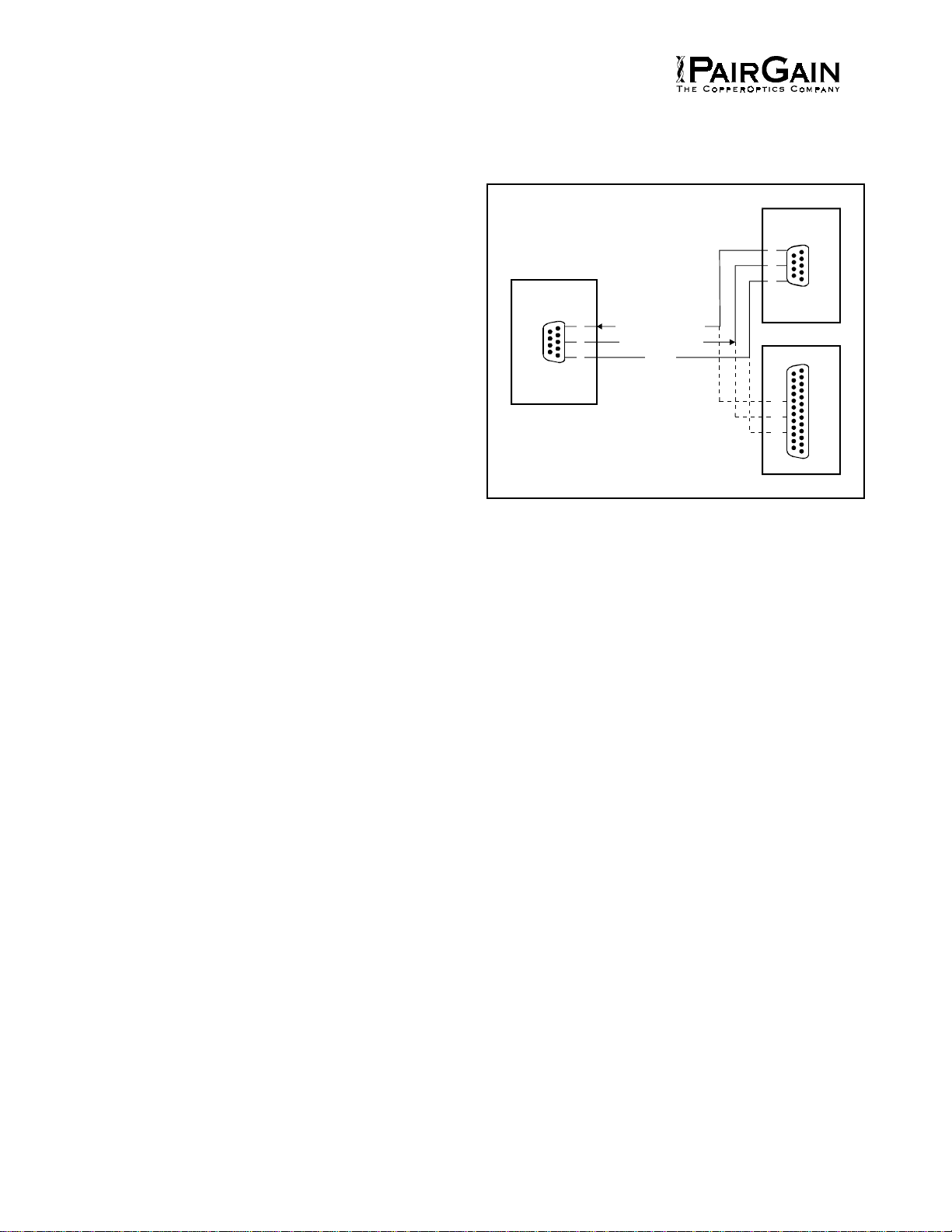

3.02 A block diagram of the ELU-319 is shown in

Figure 2. The HiGain ELU-319 receives a

2.048 Mbps data stream from the G.703 digital

cross-connect interface.

3.03 The ELU-319 contains a demultiplexer that

generates two parallel 1040 kbps data

streams. Each data stream consists of HDSL

frames that are nominally 4704 bits (4.5

milliseconds) in length. Each frame contains a 14-

bit Frame Sync Word (FSW), a 6-bit Cyclic

Redundancy Check (CRC), a 21-bit operations

channel and 16 of the 32 G.703 timeslots. The

demultiplexer provides frame synchronization for

each of the two HDSL channels. The multiplexer

and HDSL transceivers work under control of the

ELU-319 microprocessor and compensate for data

inversions caused by tip-ring reversals and for

channel swaps caused by pair reversals. The

HiGain system tolerates tip-ring reversals, HDSL

cable pair reversals but does not tolerate split pairs.

3.04 The two formatted HDSL channels pass to

the HDSL transceivers, which convert them

to 2B1Q format. The 2B1Q line code operates in

full-duplex mode on unconditioned pairs. The

transceiver's digital echo cancelers and adaptive

equalizers receive the signal from the remote end in

the presence of impairments and noise on the