OPERATIONMANUALPROMO®2000

PALAS®GMBH,MARCH2010,VERSIONV0010320102

CONTENTS:

1IMPORTANTNOTES!!!.......................................................................................................4

2INSTALLATIONANDFIRSTOPERATION.............................................................................5

2.1Mainsvoltagecheck......................................................................................................5

2.2Auxiliaryequipmentcheck............................................................................................5

3CONNECTINGTHESENSOR................................................................................................6

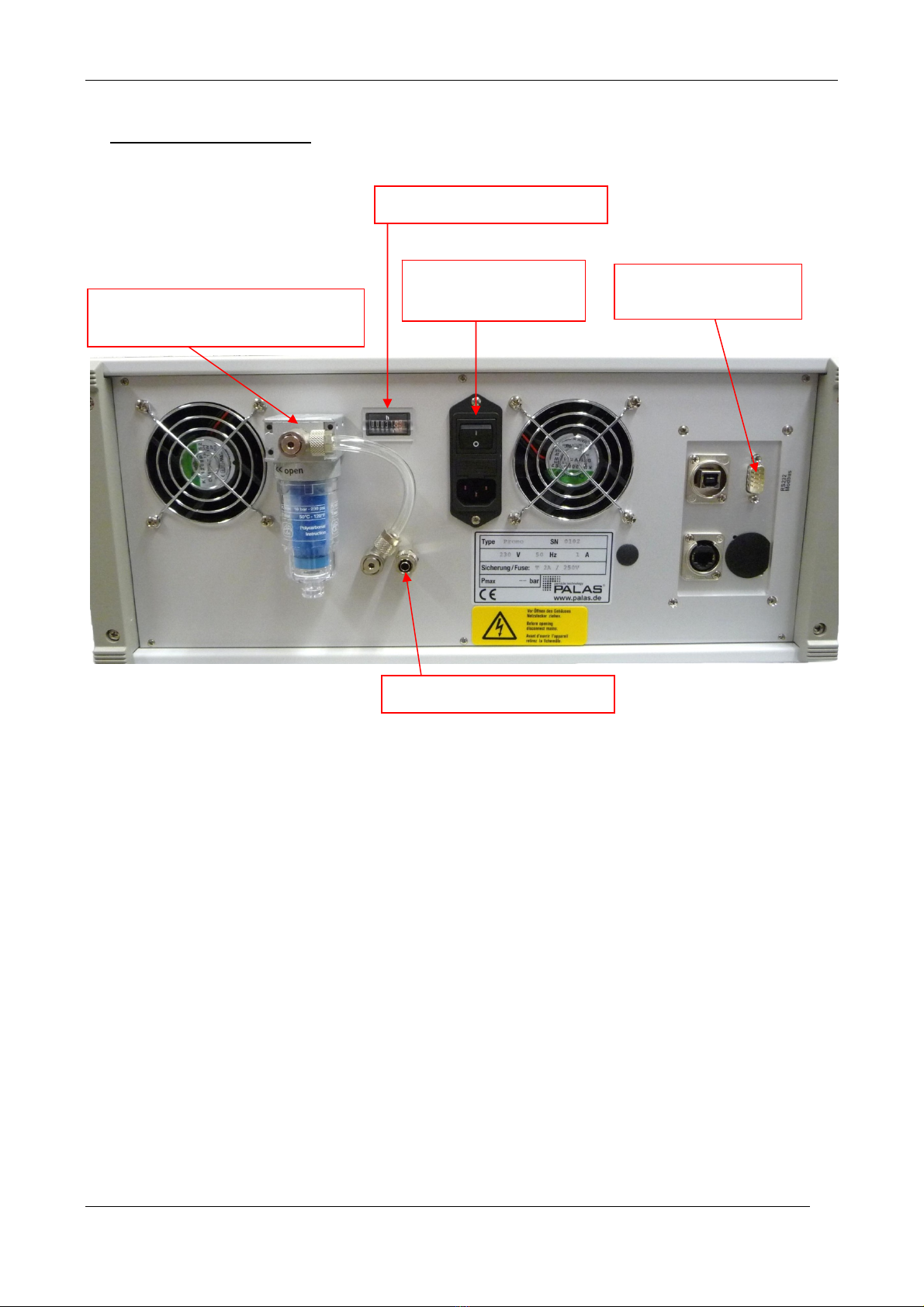

3.1Rearsideofthecontrolunit..........................................................................................6

3.2Frontsideofthecontrolunit.........................................................................................7

3.2.1Completeconnectionofthecontrolunit....................................................................8

3.3Connectionofthesensor..............................................................................................9

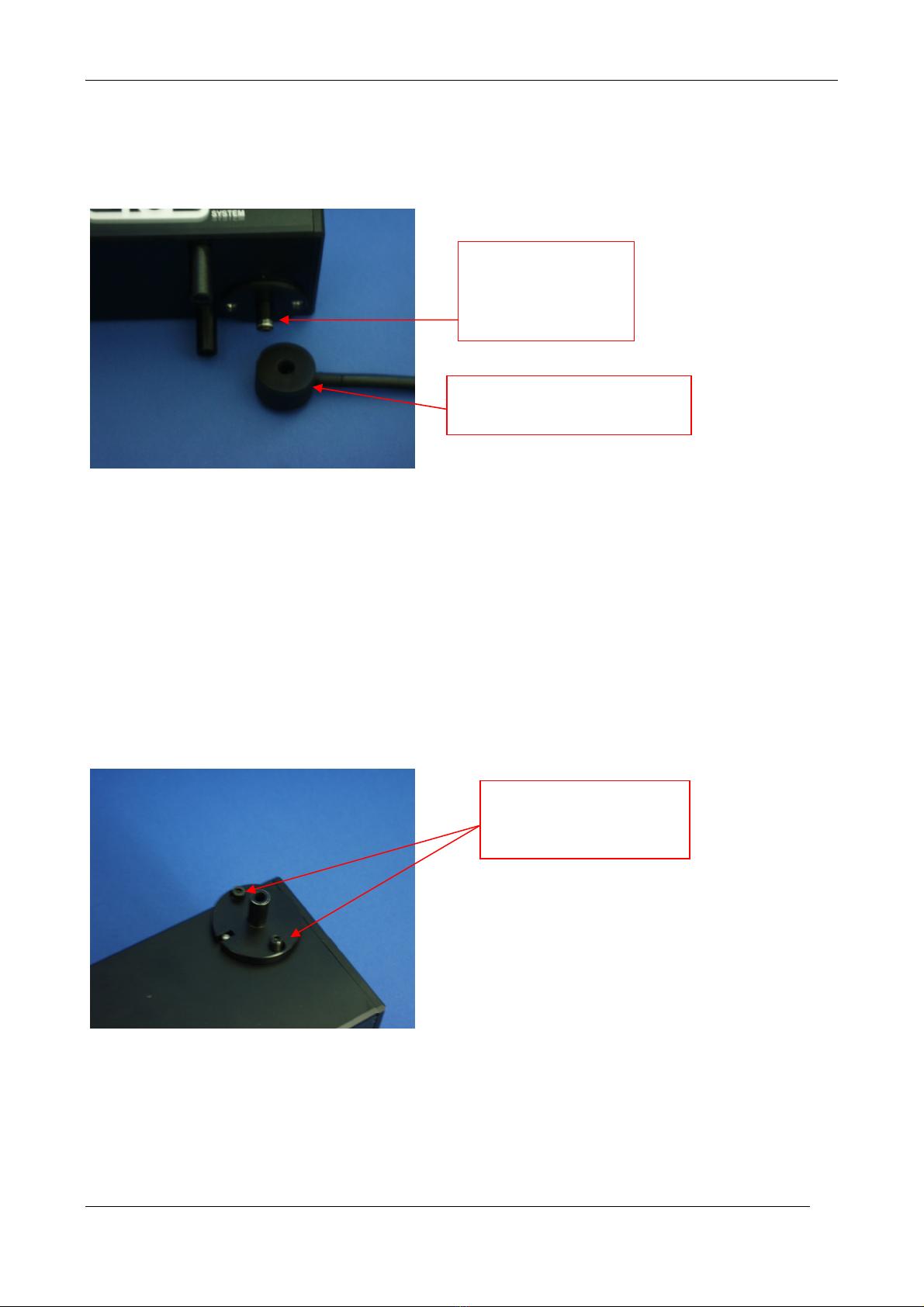

3.3.1Uppersideofthesensor............................................................................................9

3.3.2Bottomviewofthesensor.......................................................................................10

3.4Cleaningthesensor.....................................................................................................10

3.4.1Howtocleanthesensor..........................................................................................10

3.5Handlingoflightwaveconductorcables.....................................................................12

3.6Fibertest......................................................................................................................13

3.7Lampexchange...........................................................................................................15

3.8Lossofwarranty..........................................................................................................16

4CALIBRATIONOFTHESENSORWITHCALDUST1100.......................................................17

4.1HowtocalibrateyoursensorfortheselectedmeasurementrangewithCalDust1100?

18

4.2Calibrationofthevelocity:..........................................................................................19

5ENSURINGCORRECTTESTCONDITIONS..........................................................................20

5.1Measurementerrors...................................................................................................20

5.1.1Methodicerrors.......................................................................................................21

5.1.2Accidentalerrors.....................................................................................................21

5.1.3Agrosserror............................................................................................................21

5.2Importantcomparison................................................................................................22

5.3Erroridentificationofopticalmeasuringdevices.........................................................23

5.4Advantagesofcountingmeasuringprocedures...........................................................23

5.5Opticalparticlemeasurement.....................................................................................24

5.6Termsofopticalparticlemeasurement.......................................................................24

5.7Determinationofinteractionrelations........................................................................24

5.8Particlecharacteristics/Equivalentdiameter...............................................................25

5.8.1Particlecharacteristics............................................................................................25

5.8.2Equivalentdiameterof............................................................................................26

5.9Opticallimitationofthemeasuringvolume................................................................26

5.10Resolutioncapacityandclassificationaccuracy...........................................................27

6PARTICLEMEASUREMENTWITHPROMO®......................................................................28

6.1SpecialfeaturesofthePromo®system.......................................................................28

6.2Clearcalibrationcurve................................................................................................29