5

Palmgren Operating Manual & Parts List 9681109 & 9681108

INSTALLATION (CONTINUED)

•Do not remove or alter grounding prong in any manner. In the

event of a malfunction or breakdown, grounding provides a

path of least resistance for electrical shock.

WARNING: Do not permit fingers to touch the terminals of plug

when installing or removing from outlet.

•Plug must be plugged into matching outlet that is properly in-

stalled and grounded in accordance with all local codes and or-

dinances. Do not modify plug provided. If it will not fit in outlet,

have proper outlet installed by a qualified electrician.

•Inspect tool cords periodically, and if damaged, have repaired

by an authorized service facility.

•Green (or green and yellow) conductor in cord is the grounding

wire. If repair or replacement of the electric cord or plug is nec-

essary, do not connect the green (or green and yellow) wire to a

live terminal.

•Where a 2-prong wall receptacle is encountered, it must be re-

placed with a properly grounded 3-prong receptacle installed

in accordance with National Electric Code and local codes and

ordinances.

WARNING: This work should be performed by a qualified

electrician.

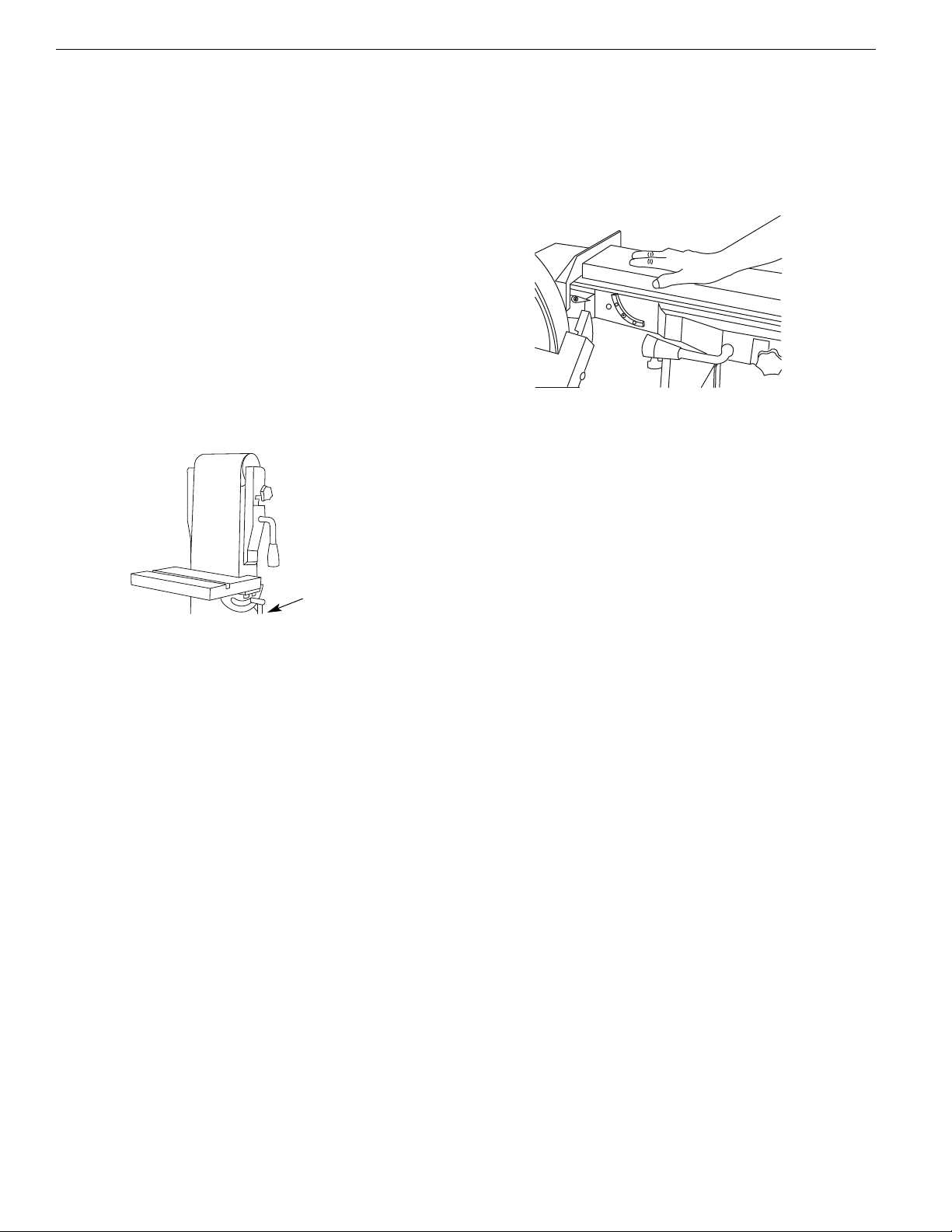

•A temporary 3-prong to 2-prong grounding adapter (See Figure

6) is available for connecting plugs to a two pole outlet if it is

properly grounded.

•Do not use a 3-prong to 2-prong grounding adapter unless per-

mitted by local and national codes and ordinances.

(A 3-prong to 2-prong grounding adapter is not permitted in

Canada.) Where permitted, the rigid green tab or terminal on

the side of the adapter must be securely connected to a perma-

nent electrical ground such as a properly grounded water pipe,

a properly grounded outlet box or a properly grounded wire

system.

•Many cover plate screws,water pipes and outlet boxes are not

properly grounded.To ensure proper ground, grounding means

must be tested by a qualified electrician.

EXTENSION CORDS

•The use of any extension cord will cause some drop in voltage

and loss of power.

•Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

•Running the unit on voltages which are not within ±10% of the

specified voltage may cause overheating and motor burn-out.

•Use the table to determine the minimum wire size (A.W.G.) ex-

tension cord.

•Use only 3-wire extension cords having 3-prong grounding

type plugs and 3-pole receptacles which accept the tool plug.

•If the extension cord is worn, cut or damaged in any way, re-

place it immediately.

ELECTRICAL CONNECTIONS

WARNING: All electrical connections must be performed by a

qualified electrician. Make sure tool is off and disconnected from

power source while motor is mounted, connected,reconnected or

anytime wiring is inspected.

•Motor and wires are installed as shown in wiring diagram (See

Figure 7). Motor is assembled with approved, 3-conductor cord

to be used at 120/240 volts.Motor is prewired at the factory for

120 volts.

Sander has a locking rocker switch with removable key for safe and

easy operation

•Remove the key from the locking rocker to prevent unautho-

rized use of the tool.To replace the key, press key into the slot

on the locking rocker.

•To use the sander witha 240V power supply, have a qualified

electrician rewire motor and attach a 240 volt three-prong plug

onto sander line cord.

Sander also has a thermal overload protector to prevent damage to

motor and other electrical components.The thermal overload pro-

tector will get activated when high temperature conditions are ob-

served while operating the tool.This will turn the tool off to

prevent temperature buildup. If that occurs, give adequate time for

the sander to cool down and depress the reset button once.The

tool will be ready to operate.

OPERATION

Refer to Figure 7.

WARNING: Operation of any power tool can result in foreign ob-

jects being thrown into eyes which can result in severe eye dam-

age. Always wear safety goggles complying with United States

ANSI Z87.1 (shown on package) before commencing power tool

operation.

CAUTION: Always observe the following safety precautions:

•Whenever adjusting or replacing any parts on the tool, turn

switch OFF and remove the plug from power source.

•Recheck table handles.They must be tightened securely.

•Make sure all guards are properly attached and securely

fastened.

•Make sure all moving parts are free and clear of any interference.

•Make sure all fasteners are tight and have not vibrated loose.

•With power disconnected, test operation by hand to verify

clearance and adjust if necessary.

•Always wear eye protection or face shield.

•Make sure abrasive belt tracks properly. Correct tracking gives

optimum performance.

•After turning switch ON, always allow belt to come up to full

speed before sanding or grinding.

•Be sure motor runs clockwise on disc side. Abrasive belt must

travel down.

•Keep your hands clear of abrasive belt, disc and all moving parts.

Figure 6 – 2-prong receptacle with adapter.

Grounding Lug

Adapter

3-Prong Plug

2-Prong Receptacle

Make sure this is

connected to a

known grounded

receptacle.

Volts

120 25 50 100 150

240 50 100 150 300

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

More Not

Than More Than Minimum Gage for Cord

Total Length of Cord in Feet

Not Recommended

Ampere Rating

Extension Cord Table