3. Measure the High Voltage. The meter reading should indicate 30.0 kV±

2.0 kV.

If the meter indication is out of tolerance, immediate service and

correction is required to prevent the possibility of premature

component failure.

4. To prevent an X-Radiation possibly, it is essential to use the specified

picture tube.

HORIZONTAL OSCILLATOR DISABLE CIRCUIT TEST SERVICE WARNING:

The test must be made as a final check before set is returned to the customer.

1. With the rear cover removed, supply about a 120 V AC power source

to the set, turn on the set.

2. Set the customer controls to normal operating positions.

3. Short between TP891 and TP892 on the Main circuit board with a

jumper wire. Confirm that the picture goes out of horizontal sync.

4. If this does not occur, the horizontal oscillator disable circuit is not

operating. Follow the Repair Procedures of horizontal oscillator

disable circuit before the set is returned to customer.

REPAIR PROCEDURES OF HORIZONTAL OSCILLATOR DISABLE CIRCUIT

1. Connect a DC voltmeter between capacitor C513 (+) on the Main

circuit board and chassis ground.

2. If approximately +21.9 V is not present at that point when 120 V AC is

applied, find the cause. Check R503, R5342, C5325, C513 and D503.

3. Carefully check above specified parts and related circuits and parts.

When the circuit is repaired, try the horizontal oscillator disable circuit

test again.

CIRCUIT EXPLANATION

HORIZONTAL OSCILLATOR DISABLE CIRCUIT

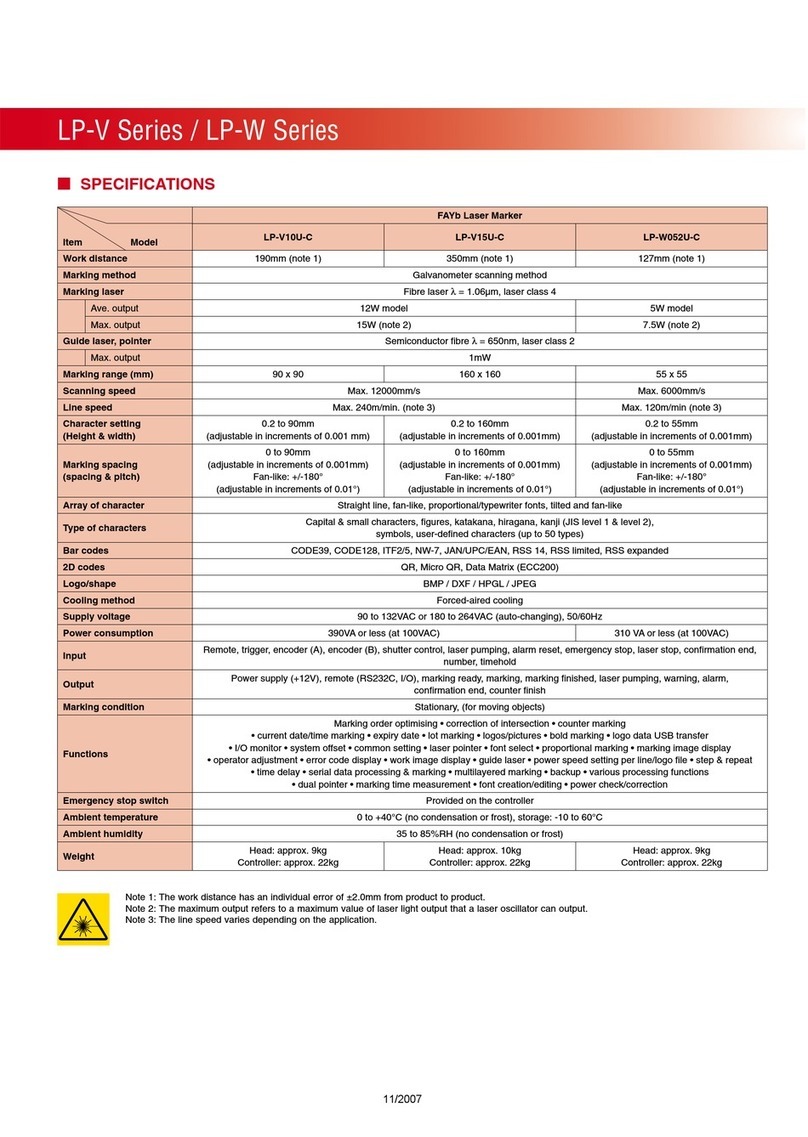

The positive DC voltage, supplied from the D503 cathode for monitoring high voltage, is applied to the

IC5301 Pin11 through R503 and R5341. Under normal conditions, the voltage at IC5301 Pin 11 is less

than approx 3 V. If the high voltage at Flyback Tr Pin 5 exceeds the specified voltage, the positive DC

voltage which is supplied from the D503 cathode also increases. The increased voltage is applied to

IC5301 Pin11 through R503 and R5341. Due to the increased voltage at IC5301 Pin11, the horizontal

oscillator frequency increases, the picture goes out of horizontal sync, the beam current decreases

and the picture becomes dark in order to keep X-radiation under specification.

Figure 2

5