Instruction Manual LEPTOSKOP 2042 Art. No. 7423.421

2

Contents Page

1Scope of delivery _________________________________________________________4

2About this manual ________________________________________________________4

3Application range_________________________________________________________5

4Important notes (read prior to first start-up!) __________________________________5

5Contacting KARL DEUTSCH ________________________________________________6

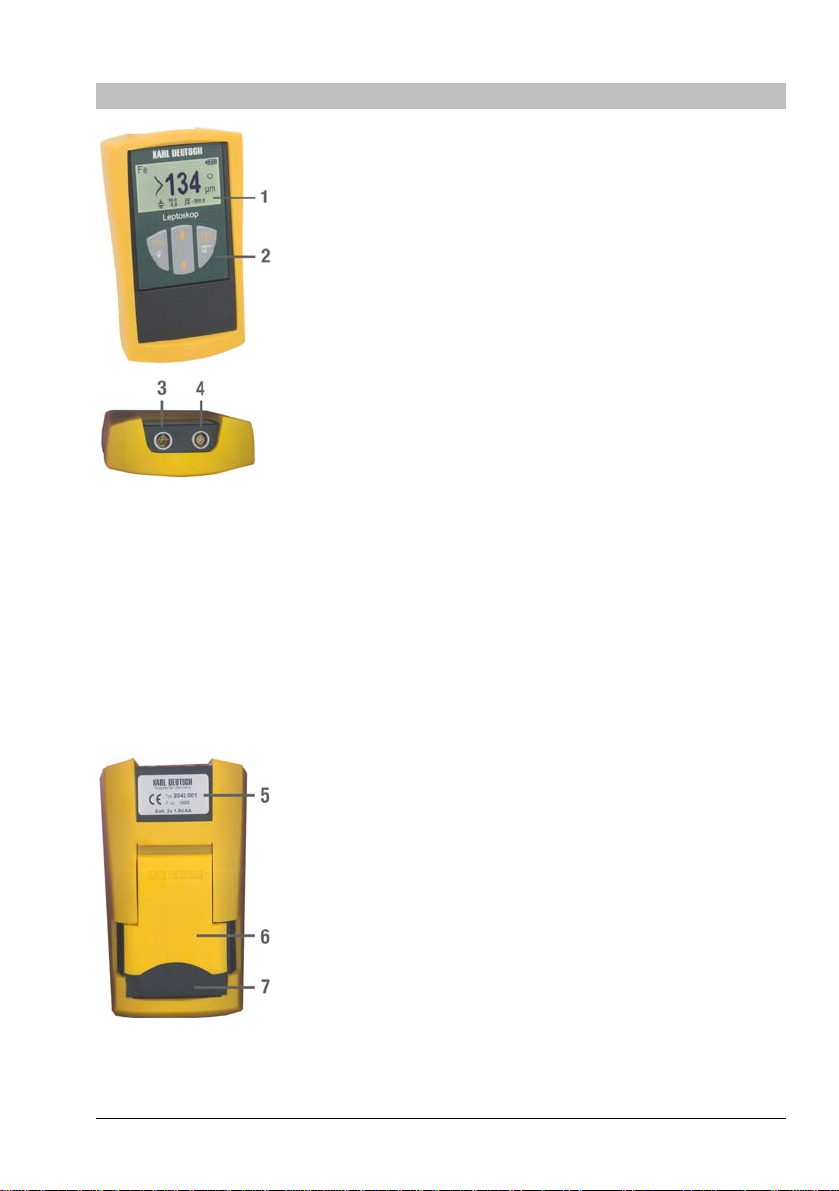

6Controls, interface and cable _______________________________________________7

7Keys and menu operation __________________________________________________8

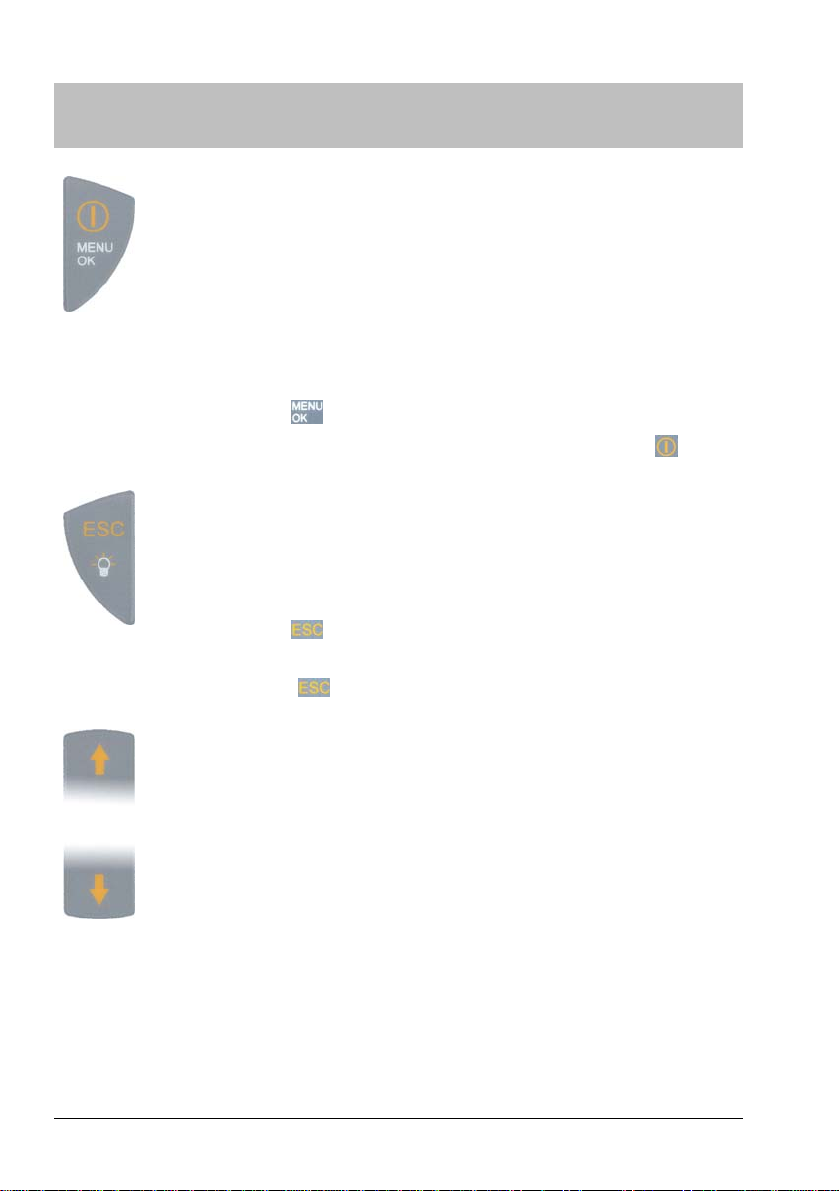

7.1 Key reference _______________________________________________________8

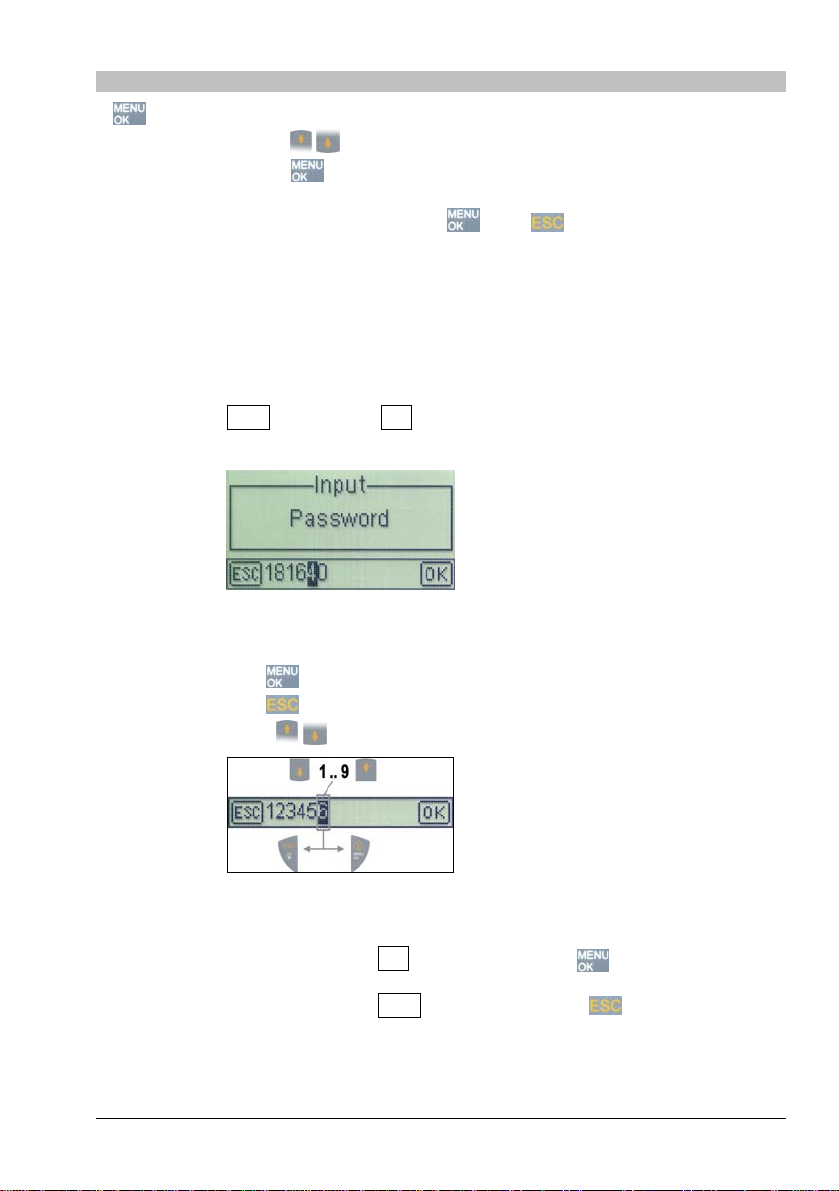

7.2 Operating___________________________________________________________9

7.2.1 Input of alpha-numeric values____________________________________9

8Putting into operation ____________________________________________________10

8.1 Insertion of battery, change of battery __________________________________10

8.2 Switching on/off ____________________________________________________11

8.3 Display____________________________________________________________11

8.3.1 Standard representation _______________________________________12

8.3.2 Statistics representation _______________________________________12

8.3.3 Analog representation_________________________________________12

8.4 Additional symbols and abbreviations in the display ______________________13

8.5 Placing the probe ___________________________________________________14

8.5.1 Particularities when placing NFe micro probes______________________14

8.5.2 Placing pressure _____________________________________________15

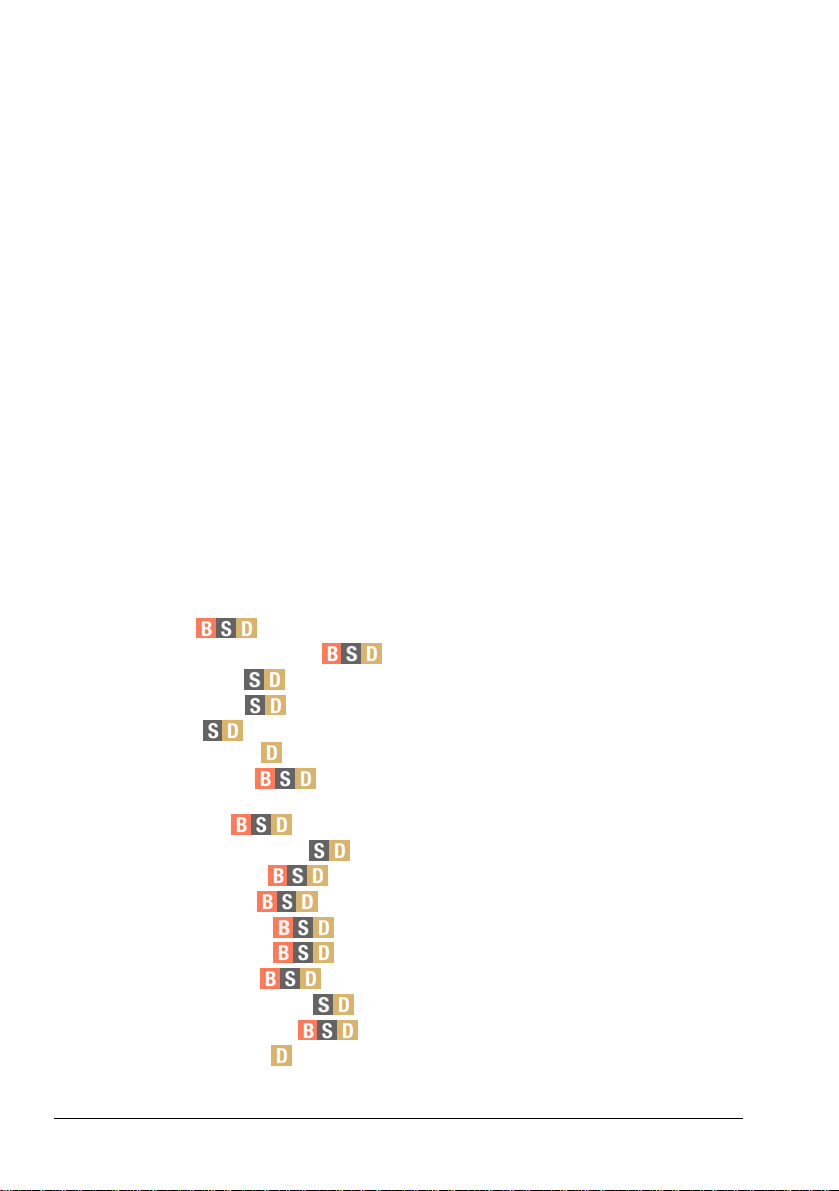

9Menu structure __________________________________________________________16

10 Menu: Selections and functions in detail_____________________________________19

10.1 Calibration_________________________________________________________19

10.2 Measure ____________________________________________________19

10.2.1 Measuring mode ______________________________________19

10.2.2 Limits ________________________________________________21

10.2.3 Offset ________________________________________________21

10.3 Statistics _____________________________________________________22

10.4 File Management _________________________________________________23

10.5 System Settings _____________________________________________26

10.5.1 Printer _____________________________________________________26

10.5.2 Unit ________________________________________________26

10.5.3 Analog Display _________________________________________27

10.5.4 Backlight ____________________________________________28

10.5.5 Volume _____________________________________________28

10.5.6 Keysound ___________________________________________29

10.5.7 Power Off ___________________________________________29

10.5.8 Hotkeys ____________________________________________29

10.5.9 Lock Keyboard _________________________________________30

10.5.10 Module Code ________________________________________30

10.5.11 et ClockS ________________________________________________30