standardsolderorsolderthat contains lead.

We will use PbF solderwhendiscussing the leadfree solderusedinourmanufacturing process

whichis made fromTin, (Sn), Silver, (Ag), and Copper, (Cu).

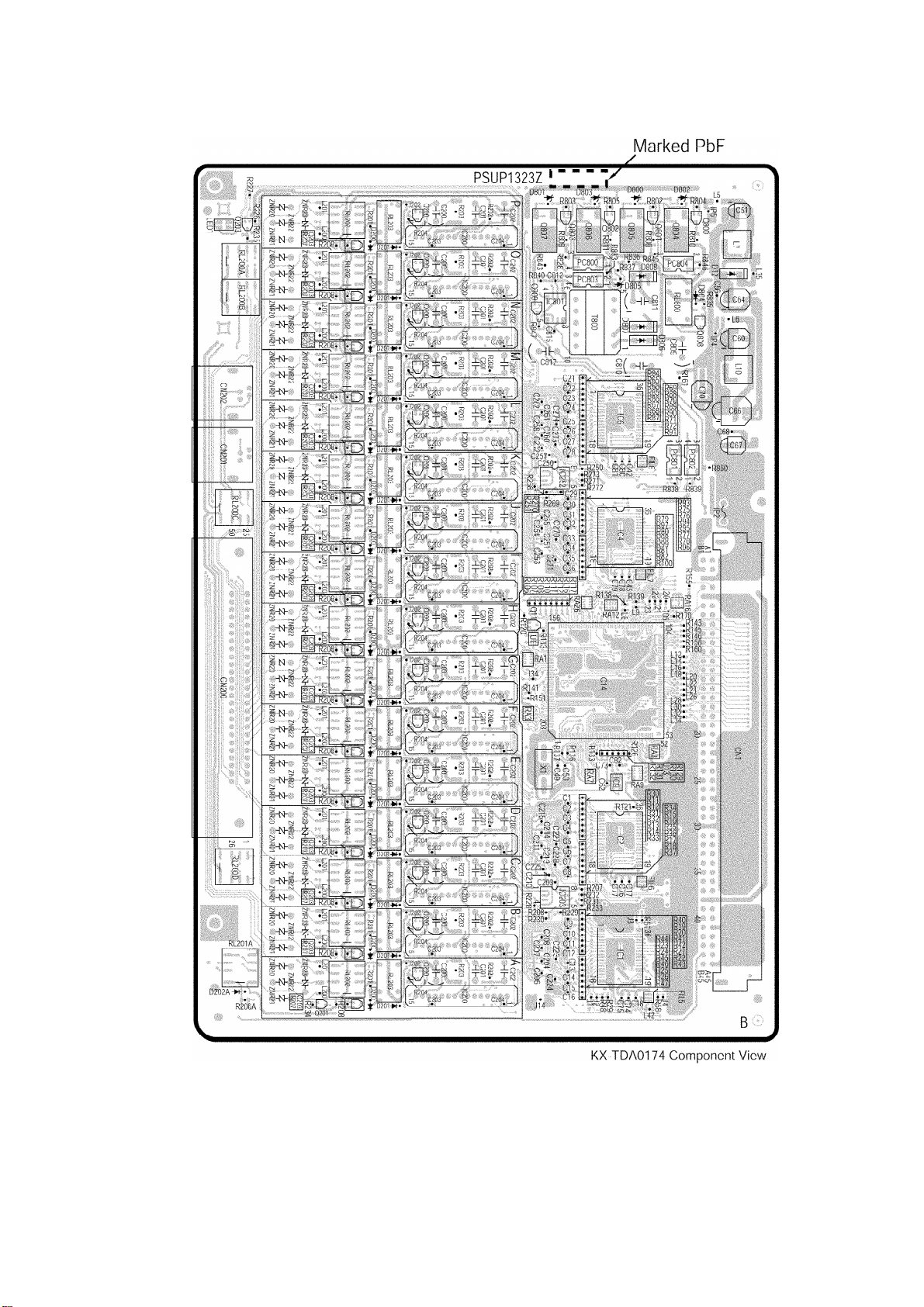

This model, and others like it, manufacturedusing leadfree solderwill have PbF stampedon

the PCB. Forservice and repairwork we suggest using the same type of solderalthough, with

some precautions, standardPbsoldercanalsobe used.

Caution

-PbF solder has amelting point that is50° ~ 70° F, (30° ~ 40°C)

higher than Pb solder. Please use asoldering iron with

temperature control and adjust itto 700° ± 20° F, (370° ± 10°C). In

case of using high temperature soldering iron, please be careful

not to heat too long.

-PbF solder will tend to splash ifitisheated much higher than its

melting point, approximately1100°F, (600°C).

-Ifyou must use Pb solder on aPCB manufactured using PbF

solder, remove as much of the original PbF solder as possibleand

be sure that anyremaining ismelted prior to applying the Pb

solder.

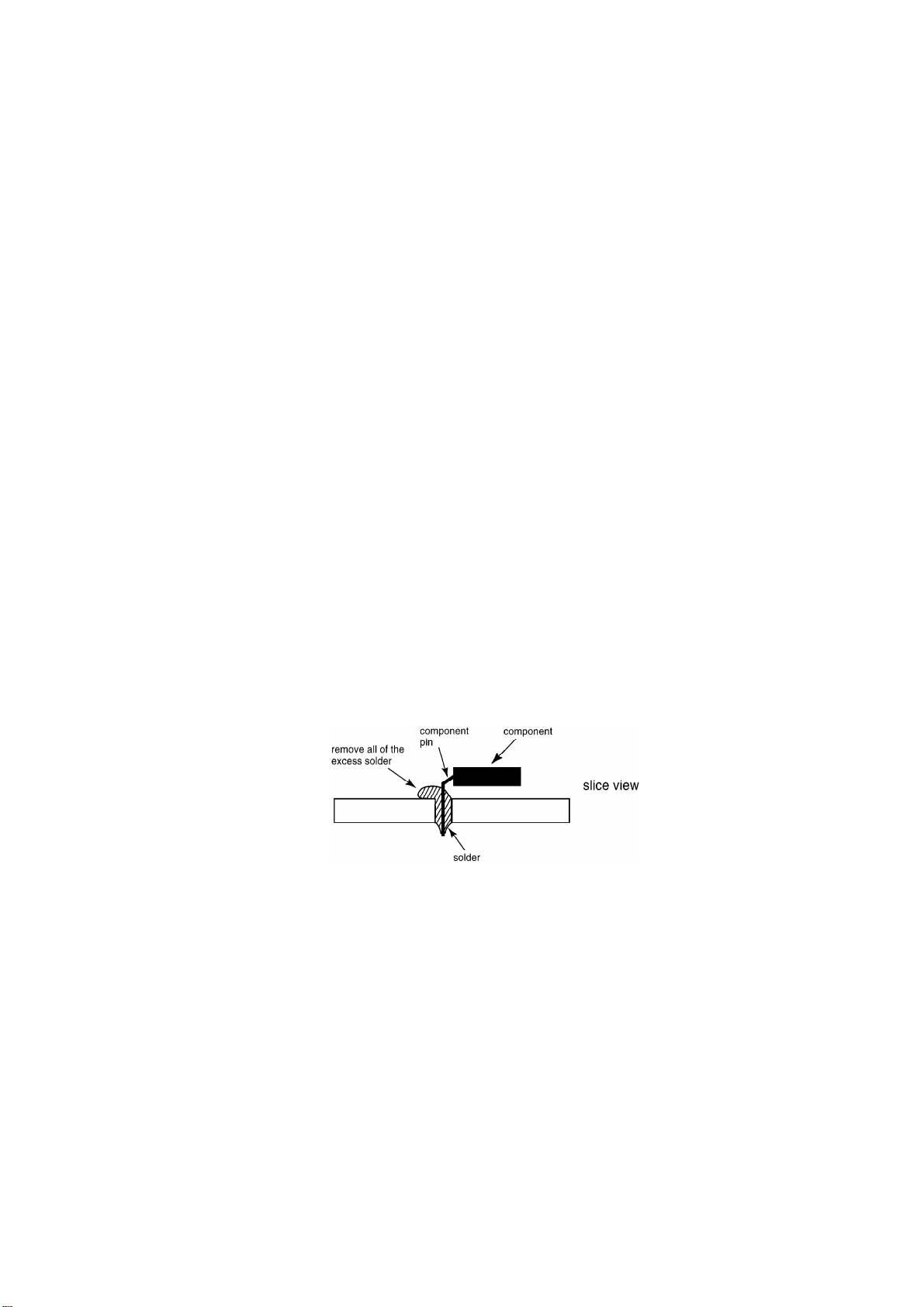

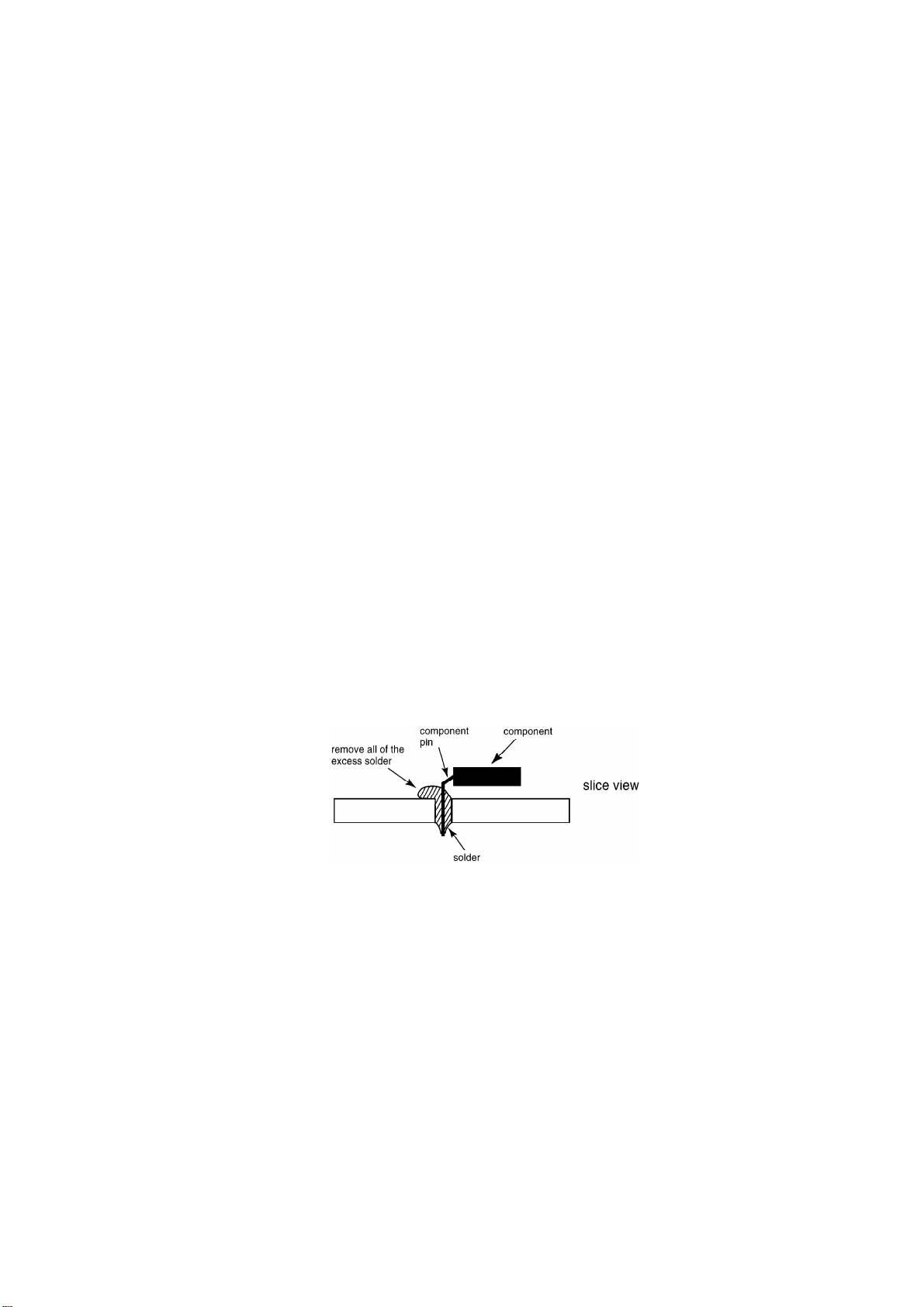

-When applying PbF solder to doublelayered boards, please check

the component side for excess which mayflow onto the opposite

side (See figure, below).

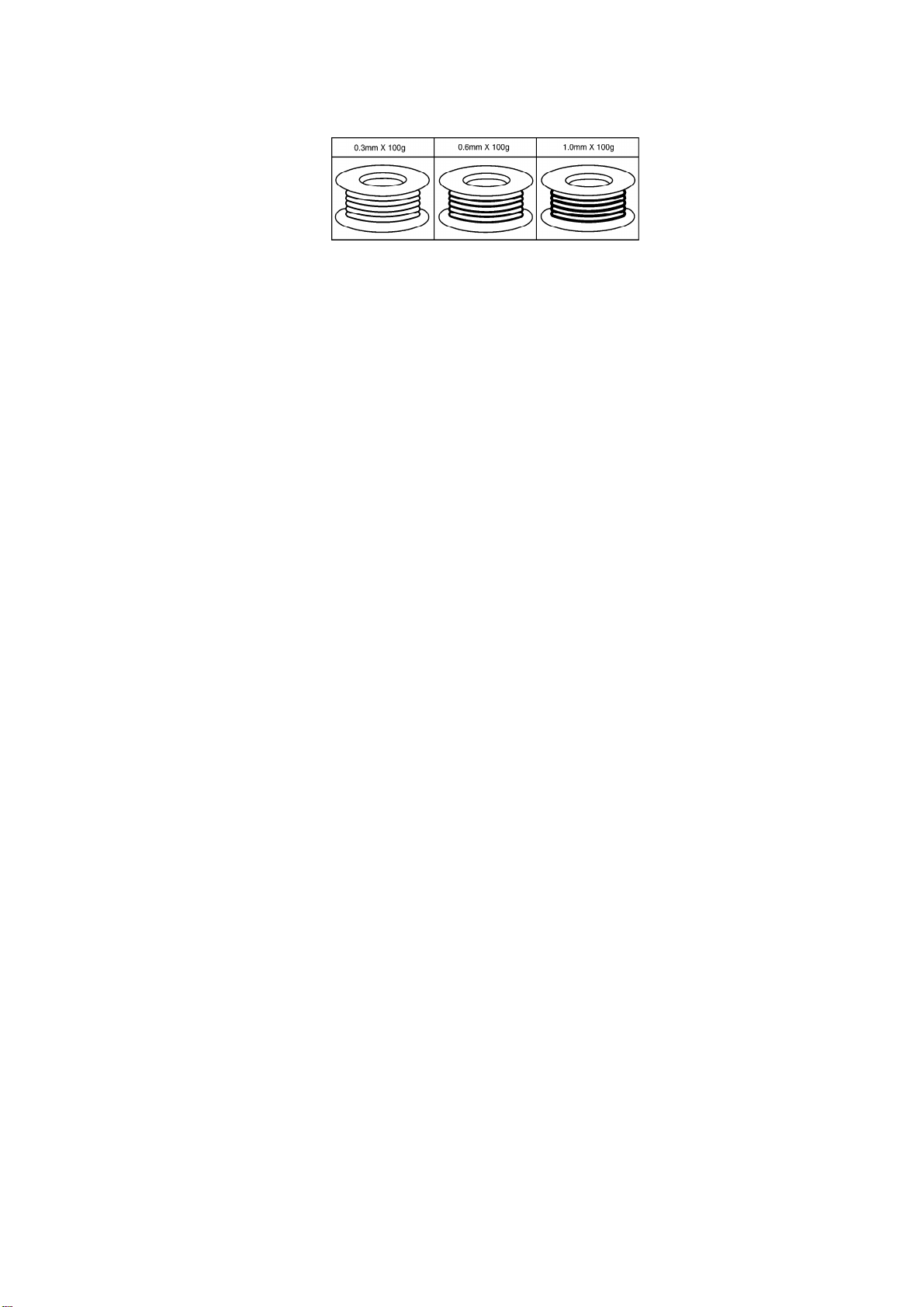

1.1. SUGGESTEDPbF SOLDER

There are several types of PbF solderavailable commercially. While this product is

manufacturedusing Tin, Silver, and Copper,(Sn+Ag+Cu), you canalsouse Tinand Copper, (Sn+

Cu), orTin, Zinc, and Bismuth, (Sn+Zn+Bi). Please check the manufacturer’s specific

instructions forthe melting points of theirproducts and anyprecautions forusing theirproduct

withothermaterials. The following leadfree (PbF) solderwire gauge are recommendedfor

service of this product: 0.3mm, 0.6mm and 1.0mm.

2