— 3 —

This appliance is classified as a CLASS 1

LASER product. The CLASS 1 LASER

PRODUCT MARKING is located on the

rear exterior.

The following caution label is located

inside the unit.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous ra-

diation exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

The laser component in this product is

capable of emitting radiation exceeding

the limit for Class 1.

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

4-987-511-2 : AEP, UK, German model

4-987-511-3 : US model

TABLE OF CONTENTS

1. SERVICING NOTE .......................................................... 4

2. GENERAL .......................................................................... 7

3. DISASSEMBLY

3-1. Tray Assembly .................................................................... 26

3-2. Bracket (Motor) ASSY ....................................................... 27

3-3. Holder ASSY ...................................................................... 27

3-4. Base Unit............................................................................. 28

3-5. HMOT Board and HLIM Board ......................................... 28

4.TEST MODE ..................................................................... 29

5. ELECTRICAL ADJUSTMENTS ............................... 32

6. DIAGRAMS

6-1. Brock Diagrams

• BD Section ....................................................................... 37

• Digital Section ................................................................. 39

• Audio Section .................................................................. 41

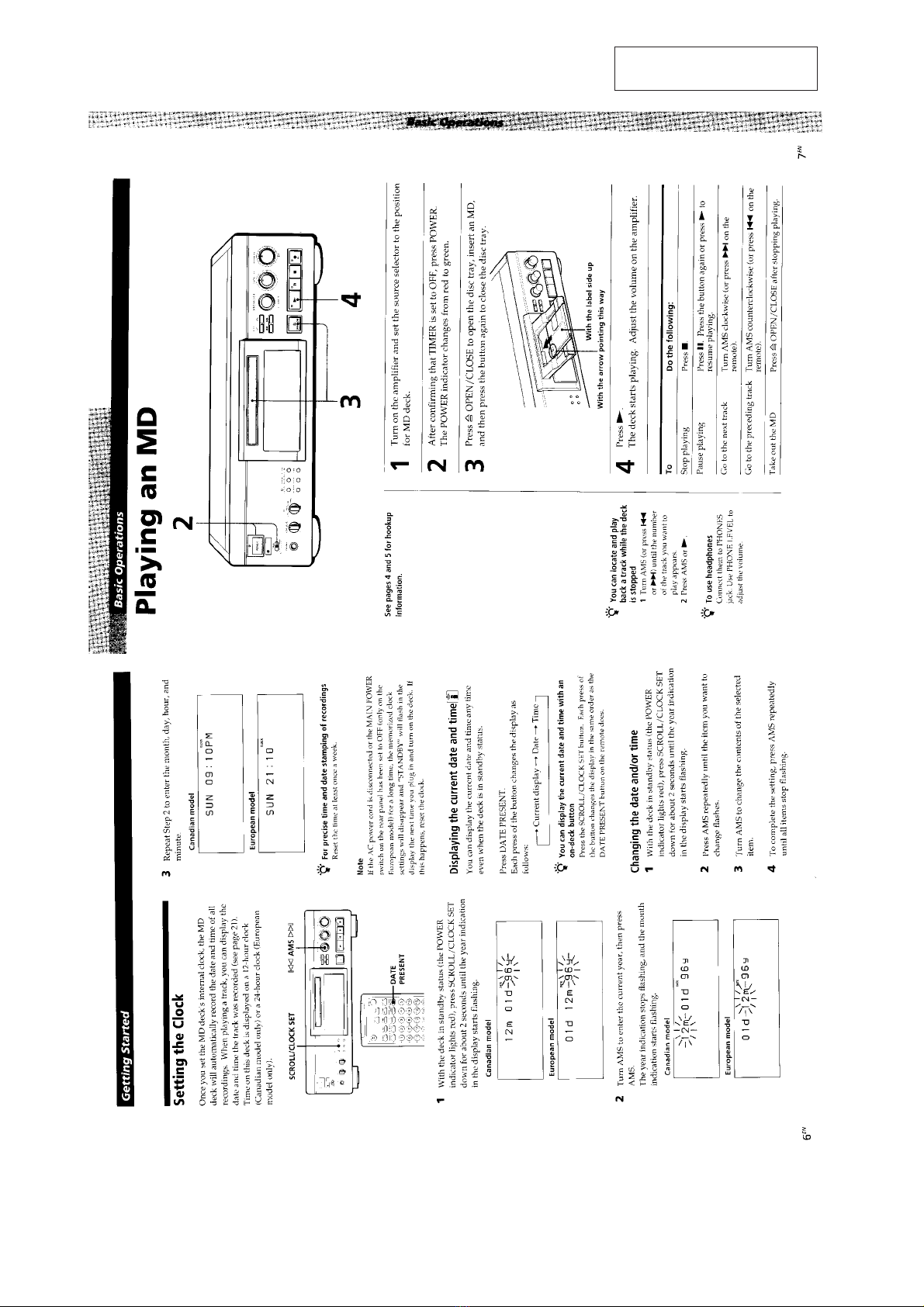

• Power Section .................................................................. 43

6-2. Circuit Boards Location ...................................................... 44

6-3. Waveforms ......................................................................... 45

6-4. Printed Wiring Board — BD Section —............................. 47

6-5. Schematic Diagram — BD Section — ............................... 49

6-6. Schematic Diagram — Digital Section —.......................... 52

6-7. Printed Wiring Board — Digital Section — ....................... 55

6-8. Printed Wiring Board — MD Section —............................ 57

6-9. Schematic Diagram — MD Section — .............................. 58

6-10. Printed Wiring Board — D Out, D Vol Section — .......... 59

6-11. Schematic Diagram — D Out, D Vol Section — ............. 60

6-12. Printed Wiring Board — DA Section —.......................... 61

6-13. Schematic Diagram — DA Section —............................. 63

6-14. Printed Wiring Board — AD Section — .......................... 65

6-15. Schematic Diagram — AD Section — ............................. 67

6-16. Printed Wiring Board — Panel Section —....................... 69

6-17. Schematic Diagram — Panal Section — ......................... 71

6-18. Printed Wiring Board — Power Section — ..................... 73

6-19. Schematic Diagram — Power Section — ........................ 75

6-20. IC Block Diagrams ........................................................... 77

6-21. IC Pin Functions ............................................................... 84

7. EXPLODED VIEWS

7-1. Main Section ..................................................................... 100

7-2. Chassis Section ................................................................. 101

7-3. Front Panel Section 1 ........................................................102

7-4. Front Panel Section 2 ........................................................103

7-5. Mechanism Section 1 (MDM-4A) ....................................104

7-6. Mechanism Section 2 (MDM-4A) ....................................105

7-7. Mechanism Section 3 (MDM-4A) ....................................106

7-8. Base Unit Section (MBU-2B) ........................................... 107

8. ELECTRICAL PARTS LIST ...................................... 108