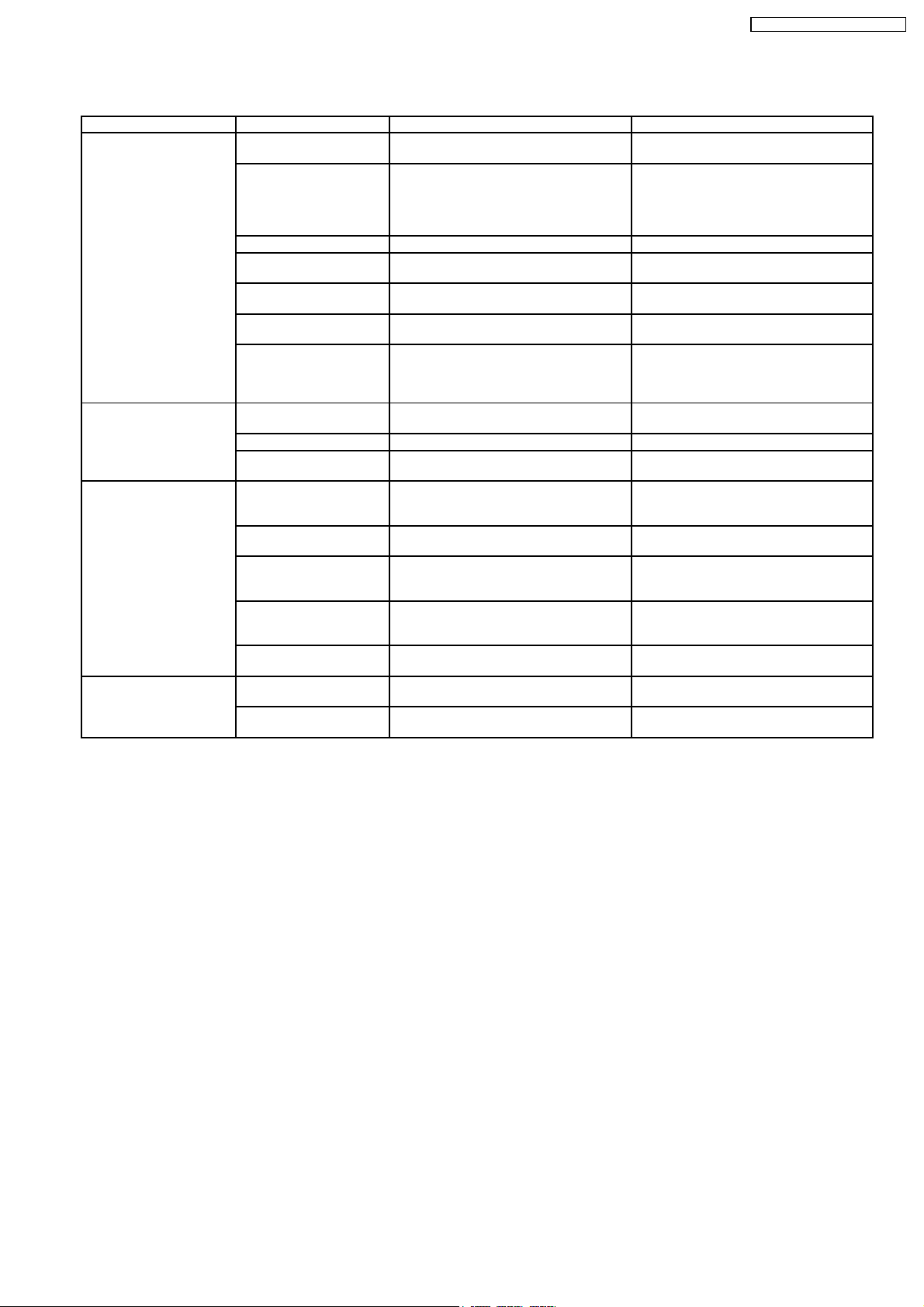

8 TROUBLE SHOOTING GUIDE

CONDITlON CHECK POINT METHOD OF INSPECTlON CAUSE/REMEDY

Motor fails to rotate.

(no noise is heard at all). Plug (fuse-1ink)

(UK, lRLonly) Check fuse continuity. lf there is no continuity, replace it.

Main fuse Check main fuse continuity. lf main fuse is blown, Check if there is any

short-circuit before replacing it. If so, repair

the short-circuit and replace the main fuse.

If there isn´t, replace the motor and main

fuse.

Mains lead Check mains lead continuity. If there is no continuity, replace it.

Motor continuity Check continuity between motor and lead

wires. If there is no continuity, replace the motor.

Carbon brushis in contact

with the commutator. Check if there is gap between carbon brush

and commutator. If there is gap between carbon brush and

commutator, replace both carbon brushes.

ON/OFF Switch Check continuity across the switch

terminals. If there is no continuity, replace ON/OFF

switch.

Thermal cut-out Check thermal cut-out continuity.

Note:

Continuity should be checked 1 hours

after removlng the plug from the socket.

lf there is no continuity, replace it.

Motor runs but there is no

suction. Hose/Suction pipe Check for any possible clog in the hose or

suction pipe. lf there is a clog, remove it.

Dust compartments Check if dust compartments are full. lf they are full, empty them.

Filter/s condition Check if filter/s is choked up. lf they are choked up, clean or replace

them.

Noise or vibration Motor fan Check if dust is accumulated in motor

fan.(lt could happen if the cleaner has been

used without central filter).

Replace the motor and check central filter

condition.(Never dismantle the motor fan).

Carbon brushes Check if there is uneven wear of carbon

brushes. If there is uneven wear, replace both

carbon brushes.

Beater bar

(bearing support A-B) Remove the beater bar ass´y and check if

bearing support A or B is broken or

deformed.

If bearing support A or B is defective,

replace it.

Beater bar (bearings) Place the beater bar ass´y on a flat surface

and turn the beater bar to check bearing

noise or distance.

If there is bearing noise or distance,

replace the beater bar ass´y.

Motor pulley (bearing) Turn motor pulley and check bearing noise. If there is a bearing noise, replace motor

pulley.

Beater bar does not rotate Belt/s Remove base plate and check if any of the

two belts is broken or loose. If any of them is broken, replace it. If loose*

re-install it.

Motor pulley Remove the base plate and check if motor

pulley is blocked. lf it is blocked, replace it.

13

MC-E4111-KP47 / MC-E4113-KP47