1

TABLE OF CONTENTS

TABLE OF CONTENTS..............................................................................................................................................1

1: INTRODUCTION..................................................................................................................................................3

2: SYSTEM SPECIFICATIONS....................................................................................................................................3

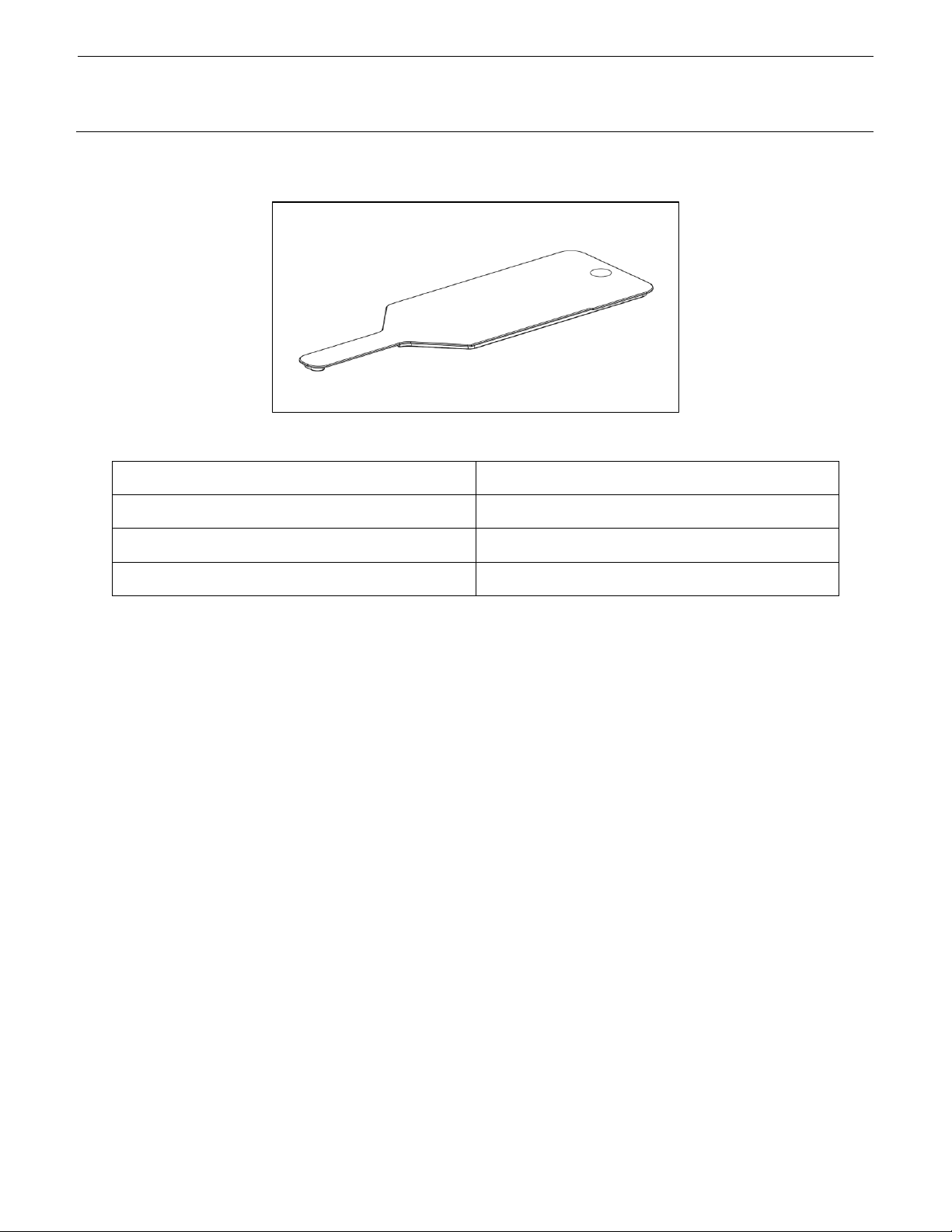

2A: PATMFM4.0 Table-Top Fixture ...........................................................................................................................3

2B: Fixture Tool Cage.................................................................................................................................................4

2C: EI Communication Cable .....................................................................................................................................5

2D: Tip Deflector........................................................................................................................................................6

2E: Tool Cavity Cover.................................................................................................................................................6

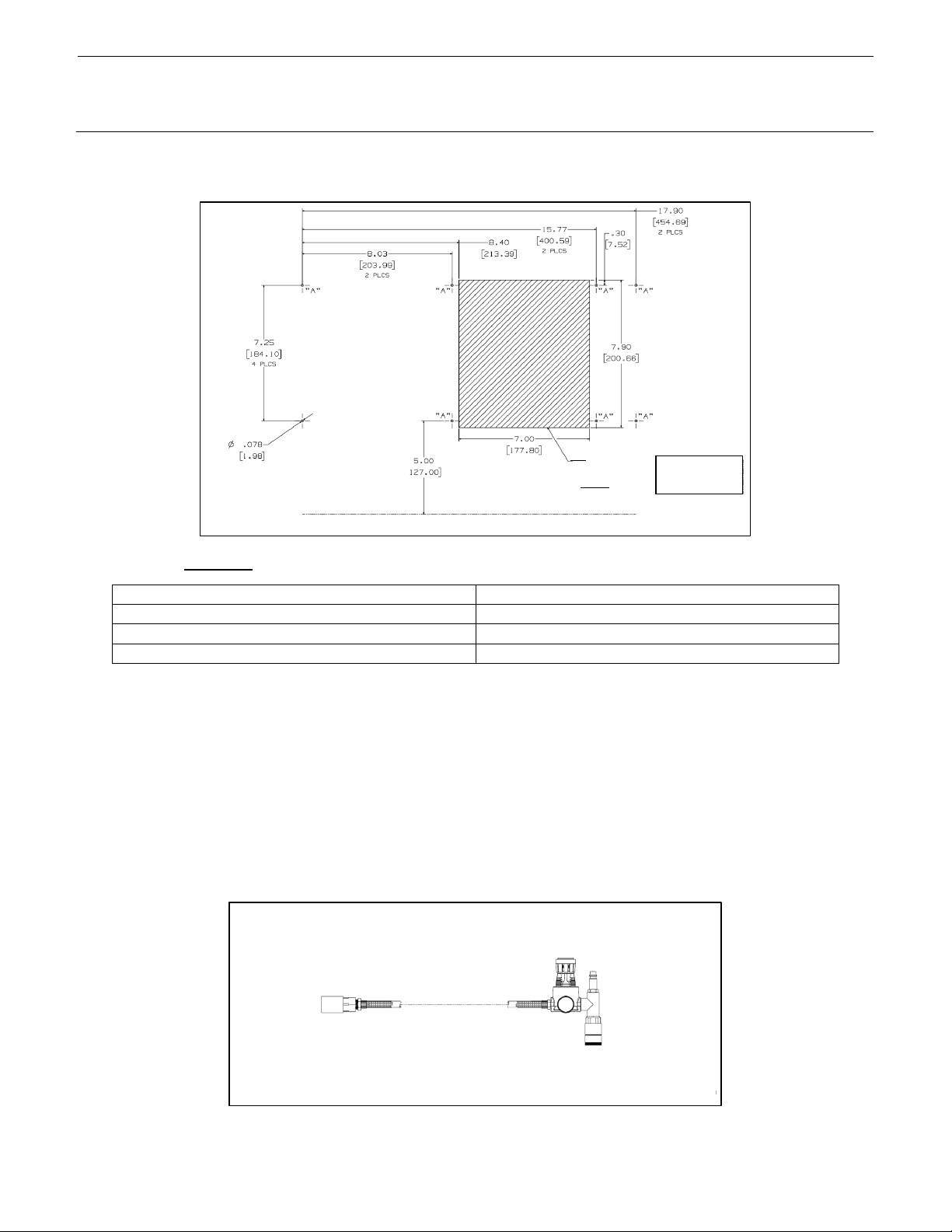

2F: Table-Top Template.............................................................................................................................................7

2G: Air Regulator.......................................................................................................................................................8

3: GENERAL POWER TOOL SAFETY WARNINGS ......................................................................................................9

3A: Work Area Safety....................................................................................................................................9

3B: Operational Safety Practices ................................................................................................................11

3C: Personal Safety .....................................................................................................................................11

3D: Power Tool Use and Care .....................................................................................................................12

3E: Service...................................................................................................................................................13

4: TECHNICAL SPECIFICATIONS............................................................................................................................. 13

4A: Air Supply ..........................................................................................................................................................13

4B: Environmental ...................................................................................................................................................14

5: INSTALLATION / SETUP ....................................................................................................................................14

5A: Take Inventory ..................................................................................................................................................14

5B. What’s Included.................................................................................................................................................14

5C. Modify Work Surface with Template................................................................................................................14

5D. PATMFM4.0 Fixture Assembly Installation(Ensure that the PAT4.0 system is off before installation). ............14

5E. Install PAT1M4.0/PAT1.5M4.0 Tool into Tool Cage ..........................................................................................15