Page ‑ 7

Manual | English

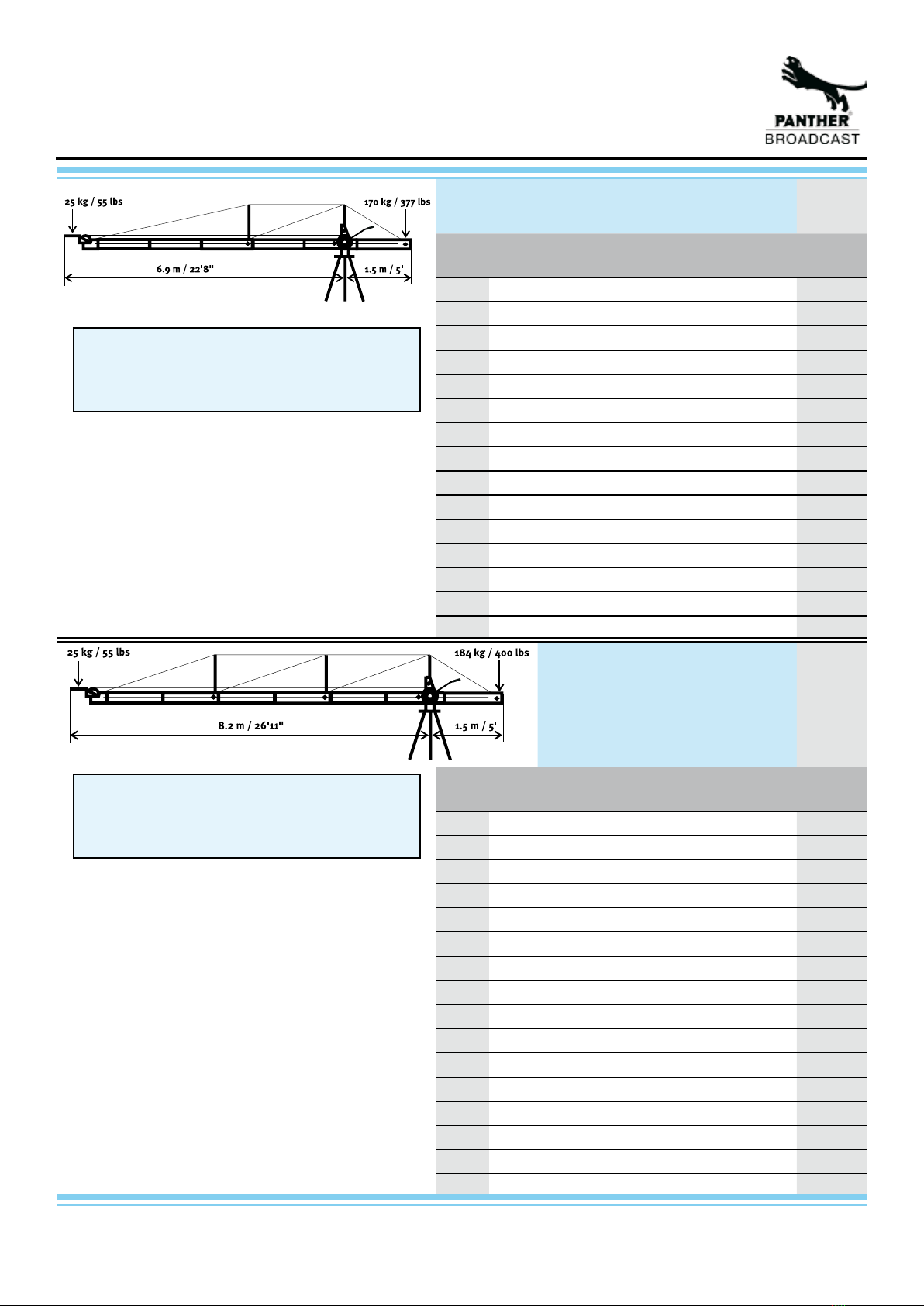

weight*

max. length

max. height

* without tripod

Eigengewicht*

Max. Länge

Max. Höhe

* ohne Stativ

25 kg / 55 lb

8.4 m / 27‘7“

7 m / 23‘

PIXY crane, version 5

PIXY Kran, Version 5

Qty.

Anzahl

consisting of

bestehend aus

code no.

Art.-Nr.

1 Pixy Tripod Pixy Stativ 138892

1 Central pivot section Mittelteil Pixy Kran 143788

1 lifting rod Pixy Hebelstange Pixy 137363

1 carrier tube Trägerrohr 143777

1 rear tube Endrohr 137097

1 weight bar Gewichtsstange 142297

3 extension tube Verlängerung 137096

1 ext. tube for bracing Verl. für Abstützung 137342

1 Mount Pixy Galgen Pixy 137098

1 base bracing Basisabspannung 137106

1

Bracing ext. for V3/5/7

Abspannungsverl.für V3/5/7

157242

1 Bracing cable V4 Abspannung V4 138383

1

Balance rod 1.6 m / 5‘3“

Parallelogramm 1,6 m 142404

3

Balance rod 1.3 m / 4‘3“

Parallelogramm 1,3 m 142405

1

Balance rod support

Parallelogrammstütze 142406

PIXY crane, version 6

PIXY Kran, Version 6

weight*

max. length

max. height

* without tripod

Eigengewicht*

Max. Länge

Max. Höhe

* ohne Stativ

29 kg / 64 lb

9.7 m / 31‘10“

8 m / 26‘3“

Qty.

Anzahl

consisting of

bestehend aus

code no.

Art.-Nr.

1 Pixy Tripod Pixy Stativ 138892

1 Central pivot section Mittelteil Pixy Kran 143788

1 lifting rod Pixy Hebelstange Pixy 137363

1 carrier tube Trägerrohr 143777

1 rear tube Endrohr 137097

1 weight bar Gewichtsstange 142297

3 extension tube Verlängerung 137096

2 ext. tube for bracing Verl. für Abstützung 137342

1 Mount Pixy Galgen Pixy 137098

1 base bracing Basisabspannung 137106

1

Bracing ext. for V3/5/7

Abspannungsverl.für V3/5/7

157242

1 Bracing cable V4 Abspannung V4 138383

1 Bracing cable V6 Abspannung V6 138397

1

Balance rod 1.6 m / 5‘3“

Parallelogramm 1,6 m 142404

4

Balance rod 1.3 m / 4‘3“

Parallelogramm 1,3 m 142405

2

Balance rod support

Parallelogrammstütze 142406