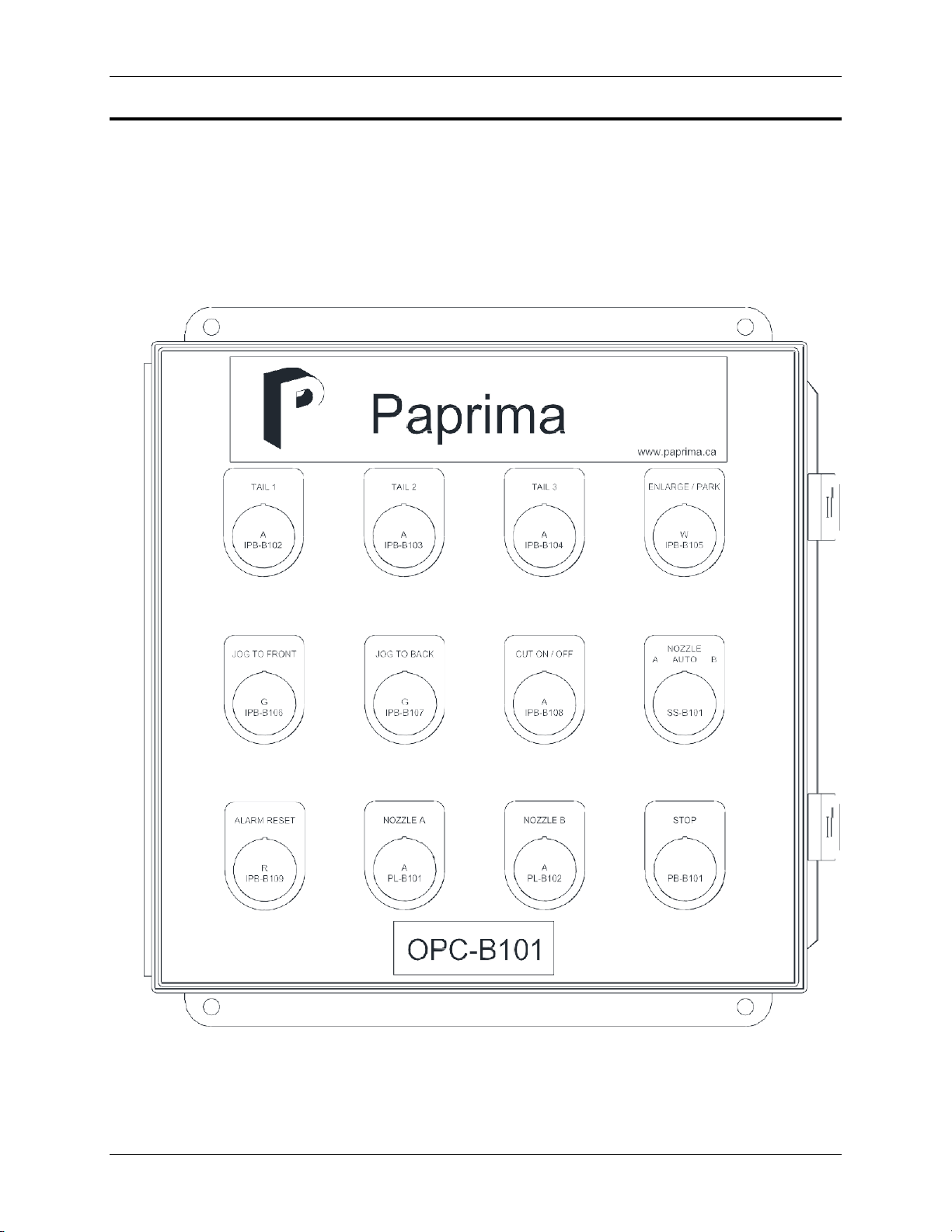

Push Buttons –POSITION

This section contains the following push buttons: TAIL 1, TAIL 2, TAIL 3, and ENLARGE /

PARK. The light of the push button is flashing when the tail cutter is travelling into position and

it turns on solid when the tail cutter is in position. Any position can be fine-tuned by pressing the

buttons JOG TO FRONT, OR JOG TO BACK. To set the last position into memory press both

buttons REPROGRAM.

Tail 1

Pressing and releasing the push button TAIL 1 moves the tail cutter carriage to its pre-set tail

position that generates the tail. At this moment one of the two jets per cutting head is coming

on.

Tail 2,3

Pressing and releasing the push buttons TAIL 2 or TAIL 3 moves the tail cutter carriage to its

pre-set tail positions, which generate a progressively wider tail. The jet remains on.

ENLARGE / PARK

Pressing and releasing the push button ENLARGE / PARK moves the tail cutter carriage over

the remaining paper width to the park position. Once in the park position the high-pressure

water jet will automatically turn off. If during tail cutting any of the three positions is selected

again, the carriages will reposition to the selected position with the jet remaining on.

Note: If the park position is on the tending side, the jet will turn off on the drive side and the jet

cutter will return at full speed to park tending side.

Push Buttons –Jog to Front / Jog to Back

Pressing either of the buttons JOG TO FRONT or JOG TO BACK allows to fine-tune the desired

new position in jog speed mode. The light for the selected tail position shuts off, and either the

JOG TO FRONT or the JOG TO BACK pushbutton light flashes rapidly indicating motion in the

selected direction of travel. To REPROGRAM the new position, press both buttons

simultaneously. Once the new position is set in memory, both pushbutton lights illuminate, and the

position light turns on solid to confirm the reprogrammed position. The carriage will now move to

the newly selected position whenever the button is pressed again.

Push Button –Cut ON / OFF

With the selector switch in the NORMAL mode, the CUT ON/OFF push button serves to turn the

jet on or off while the jet carriage is active either in a fixed tail cut position, or travelling in-between

positions. In the normal operating mode, the hydraulic power unit and the intensifiers will remain

on and the on/off command will only open and close the high pressure solenoid valve before the

tail cutting beam. If the jet is turned off in this way for more than a minute the intensifier pump and

hydraulic power unit will be automatically shut off. To indicate that the jet is on, the push button

light illuminates.