Chapter 1. InspectRx200 Operator Guide........................................................................................3

Starting, Stopping, Resetting, and Emergency Stopping the Machine..........................................3

Power Cycle and Restart Procedure...................................................................................... 5

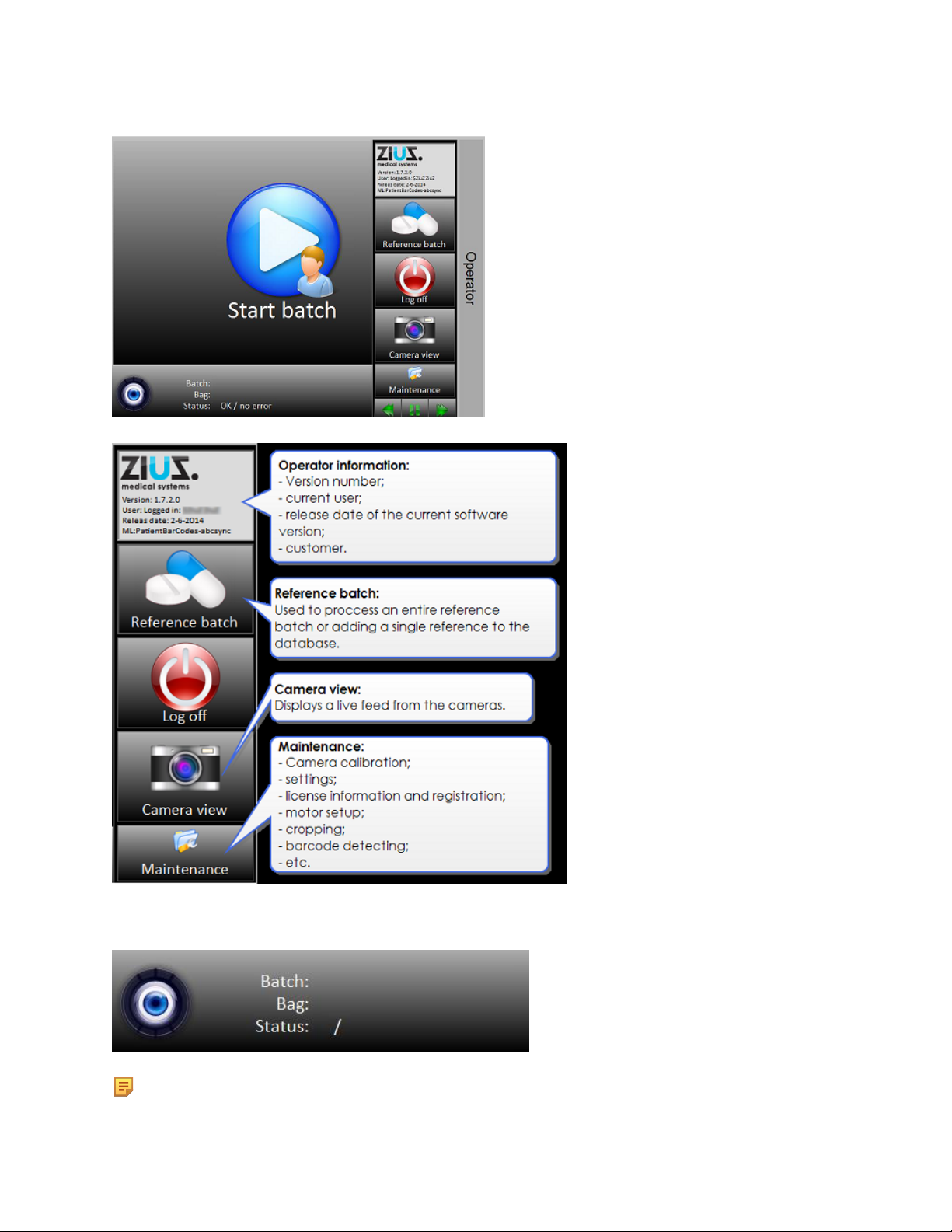

Starting Up, Logging In, and Logging Off................................................................................... 6

Starting, Scanning, and Viewing a Batch....................................................................................10

Adding a Reference Image or Batch...........................................................................................12

Reports..........................................................................................................................................16

Period Report........................................................................................................................18

Facility Report......................................................................................................................19

False Negative Report..........................................................................................................20

Medication Error Report......................................................................................................21

Reference Report..................................................................................................................23

Corrector Report...................................................................................................................24

Medications to Add Report..................................................................................................25

Medication Track Report.....................................................................................................26

User Report.......................................................................................................................... 27

Inspector Idle Time Report..................................................................................................28

Shutting Down the InspectRx......................................................................................................29

Troubleshooting............................................................................................................................29

Cleaning the InspectRx................................................................................................................30

Chapter 2. InspectRx Preventative Maintenance Guide................................................................40

Removing the Main Belt..............................................................................................................40

Installing the Main Belt...............................................................................................................45

Replacing the Infeed Belt............................................................................................................ 45

Service Bulletins & Maintenance................................................................................................46

Belt Alignment and Verification................................................................................................. 50

Camera Settings and Calibration................................................................................................. 50

InspectRx & InspectRx Pro Preventative Maintentance Kit....................................................... 56

Hardware Preventative Maintenance........................................................................................... 57

InspectRx PM Process CheckList................................................................................................58