Bulletin TI-H2PD-K Installation, Operation and Maintenance Manual

H2PD-150 and H2PD-300 Hydrogen Generators

www.parker.com/igfg

7

1-800-343-4048

All installation, operation, and maintenance procedures for the Parker Balston Hydrogen

Generator should be performed by suitable personnel using reasonable care.

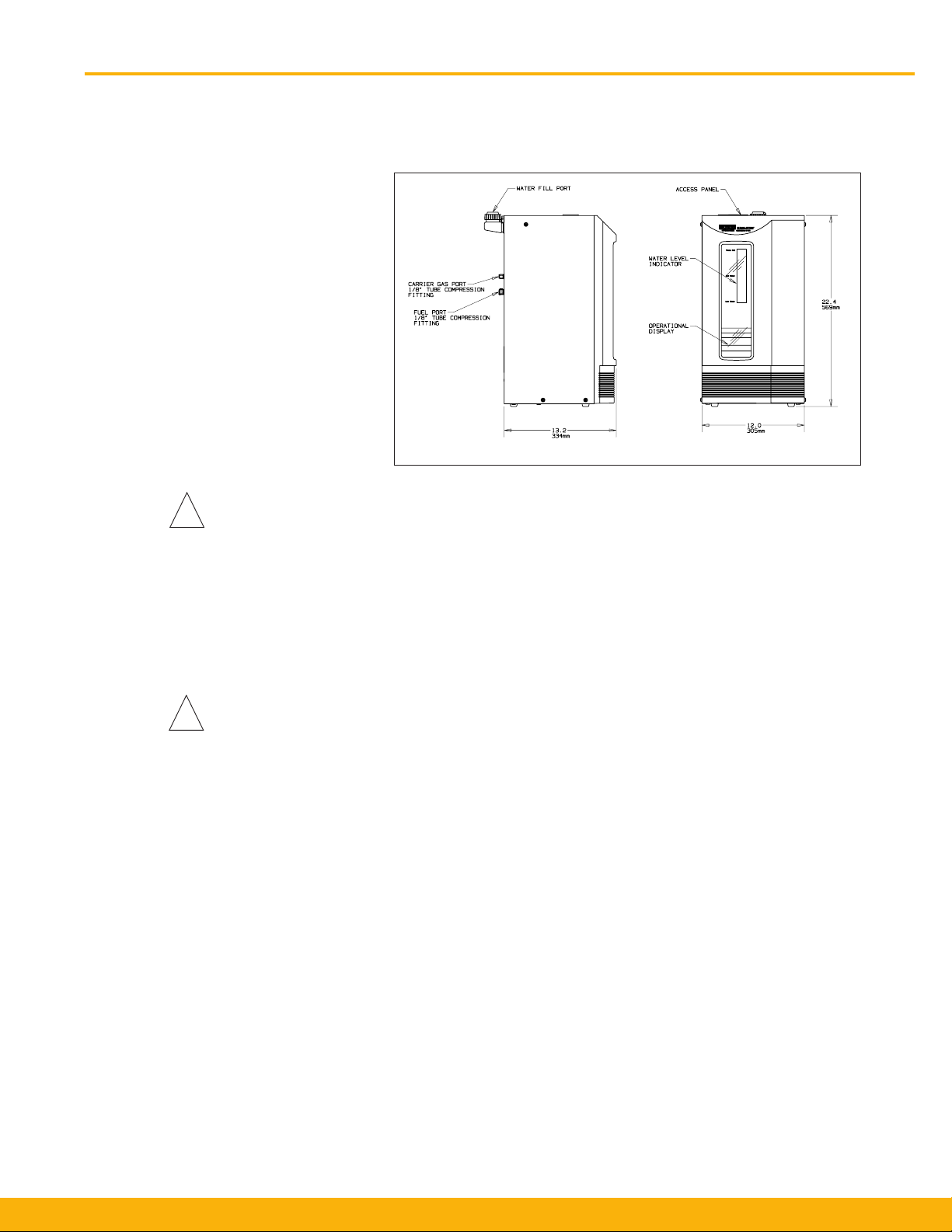

The Parker Balston H2PD-150 and H2PD-300 Hydrogen Generators are free-standing bench-top

units. Do not suspend the hydrogen generator from the wall or ceiling. Its weight and size

could pose a falling hazard. The generator should be located indoors, protected from severe

weather conditions, and free from excessive ambient dust or dirt. Do not install the generator

outdoors.Theambienttemperatureoftheairsurroundingthegeneratormustbebetween50°Fand

104°F(10°Cand40°C).Placethehydrogengeneratorinanuprightposition,onalevelsurface,in

close proximity to both the electrical power supply and the equipment requiring the hydrogen supply.

The Parker Balston Hydrogen Generator weighs 58 lbs. (26 kg.) Use proper equipment and lift-

ing techniques for transporting this equipment to its installation location. The hydrogen generator

isintendedtoremainstationarywhenlledwithwaterandelectrolyte.Ifnecessary,thegenerator

may be relocated over shortdistanceswhenlled.Do not grasp the front panel when moving

the hydrogen generator. Lift the generator by the metal case only. The generator should remain

uprightwhenmoved.Forlongdistancemoves,thegeneratormustbeshutdownanddrained.(See

Shutdown section of this manual.)

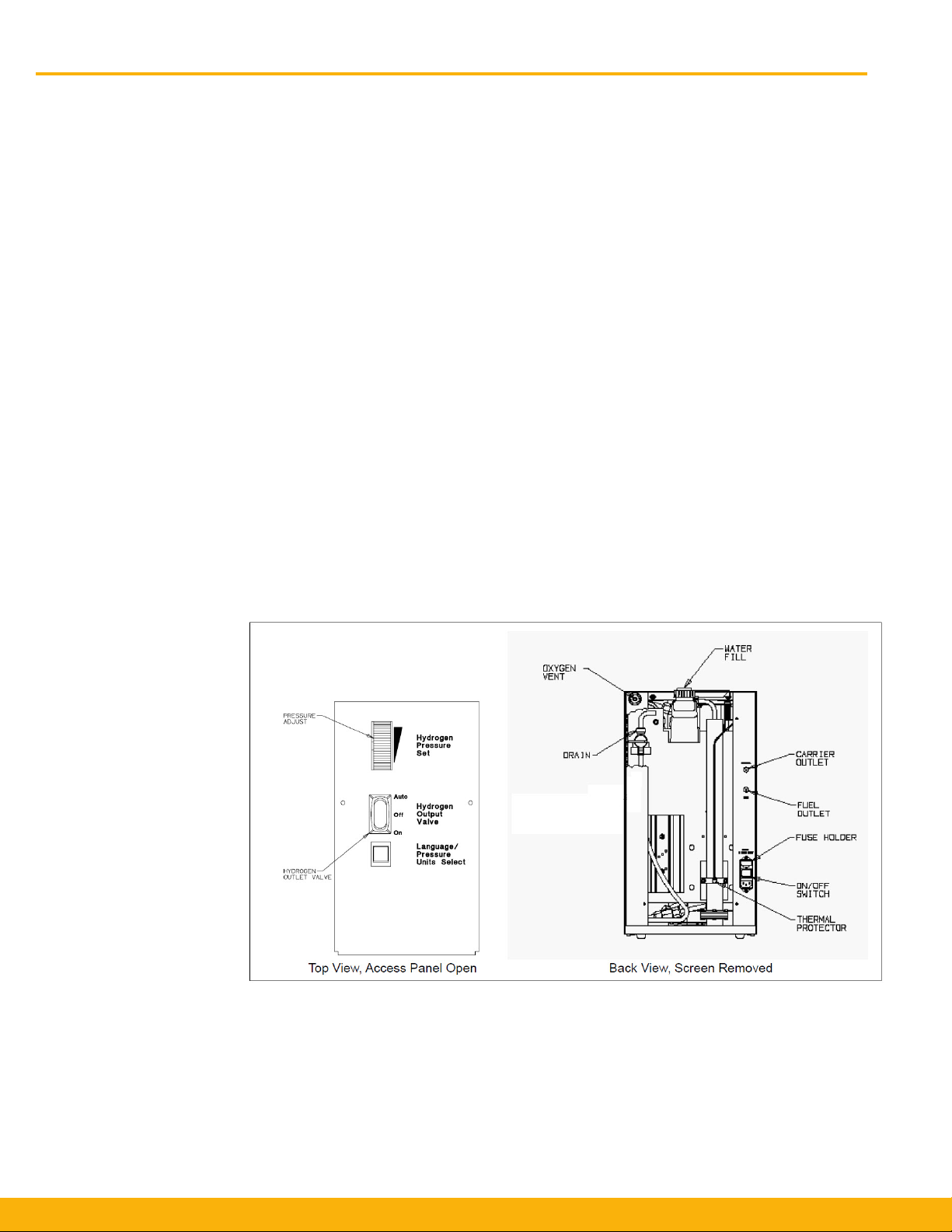

Power - The Parker Balston Hydrogen Generator may be operated by a 120 VAC or a 230 VAC,

50/60 Hz power supply. (Note: Main supply line voltage must be within ±10% of the nominal

rated voltage for the generator.) See product label on the rear panel of the hydrogen generator for

factory voltage setting. To connect the generator to the power supply, simply plug the female end of

the electrical cord into the receptacle on the right side of the generator, and the opposite end into a

three-pronged earthed power receptacle.

Note: Protect the generator from sudden, transient uctuations in electrical power by using

a surge suppressor. Parker recommends using a surge suppressor meeting the following

specications:

Joule Rating 1000 or greater

Surge Amps 84,000 or greater

Max Noise Reduction 80+ (db)

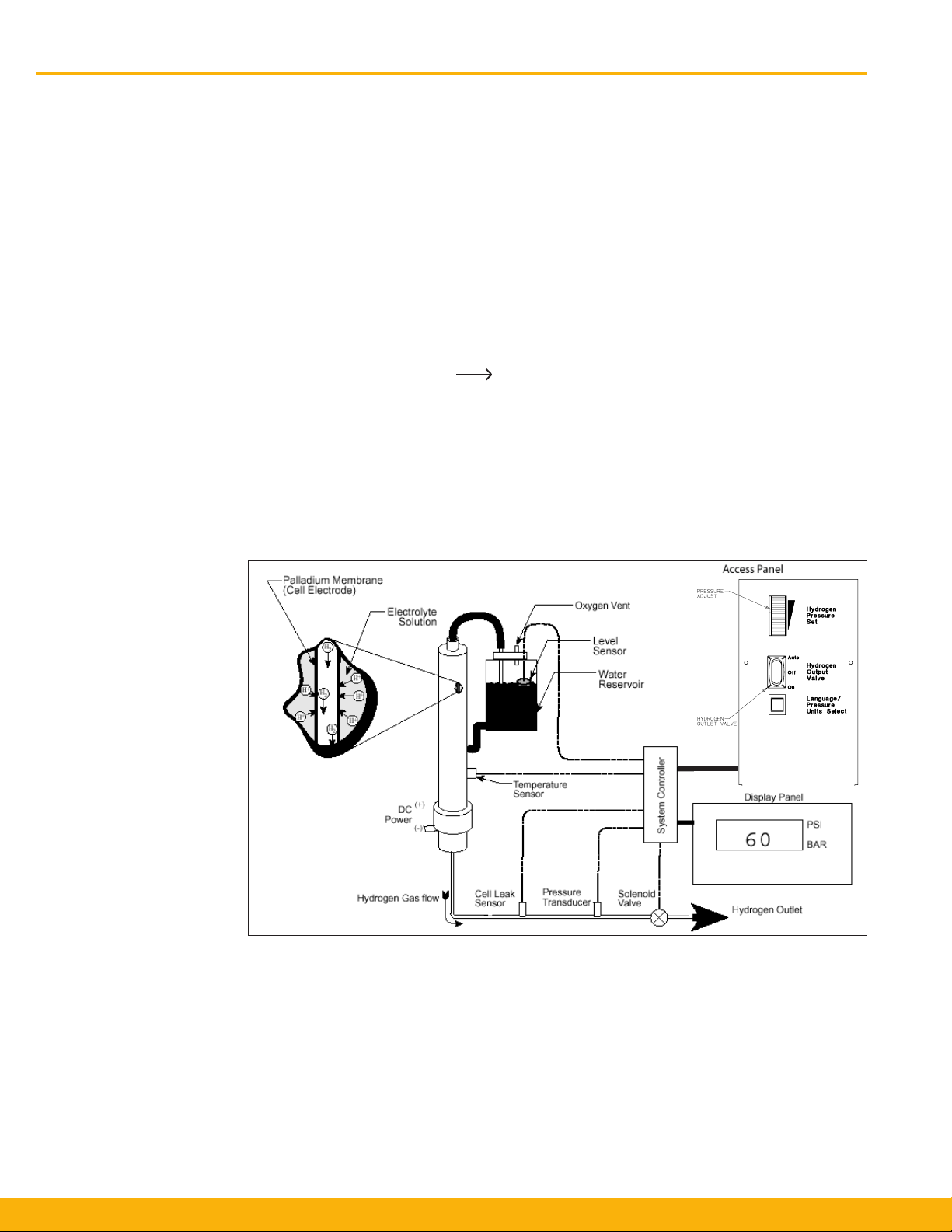

Deionized Water - The Parker Balston Hydrogen Generator must be supplied with deionized water

on a regular basis. The water should be 5 Megohm-cm, or better quality deionized water.

Caution: Do not use tap water or deionized water with less than 5 Megohm-cm resistivity.

Metallic ions and suspended solids present in substandard water may poison the palladium

membrane, rendering the cell inoperable. If the generator is operated with any liquid other

than 5 Megohm-cm (or better) deionized water, the warranty will be void.

Piping - The outlet connections for the Parker Balston Hydrogen Generators are a 1/8” compres-

siontting.Alltubingandttingsdownstreamfromthehydrogengeneratorshouldbecleanstain-

lesssteeltominimizecontaminationofthehydrogenstream.Ifcoppertubinghasbeenusedwith

hydrogen in the past and has yielded acceptable results, there is no need to alter an existing piping

congurationtoinstalltheParkerBalstonHydrogenGenerator.Thepipingcongurationforthe

hydrogen delivery system should include a means for venting subpurity hydrogen generated during

system warm-up. This may also be accomplished by disconnecting the downstream instruments.

Parker strongly recommends the installation of a shutoff valve and pressure regulator at the process

orinstrumentbeingsuppliedwithhydrogenfromthegenerator.(Iftheprocessorinstrumenthasits

own internal shutoff valve and pressure regulator to isolate it from the hydrogen line, this installation

is unnecessary.)

Forconvenience,thehydrogenstreamfromtheParkerBalstonHydrogenGeneratorismanifolded

for carrier and fuel gas applications. There is no difference in hydrogen quality between the two

ports.Thegeneratorisshippedwitha1/8"ferrulettingonthefuelgasportandapipeplugonthe

carriergasport.Ifhydrogenisbeingusedasacarriergas,simplyremovethepipeplugfromthe

carrier port and replace with the nut and ferrule supplied in the accessories bag. (Note: If one port

is not being used, it must be capped.)Thecombinedowfromthecarrierandfuelgasportsmust

not exceed the capacity of the generator.

Location

Transporting

Utilities

Piping for Carrier Gas and

Fuel Applications

Installation