Chapter

➀

Installation

1

C H A P T E R ➀

Introduction

Chapter Objective

The information in this chapter will enable you to:

❏Understand the product's basic functions & features

Product Description

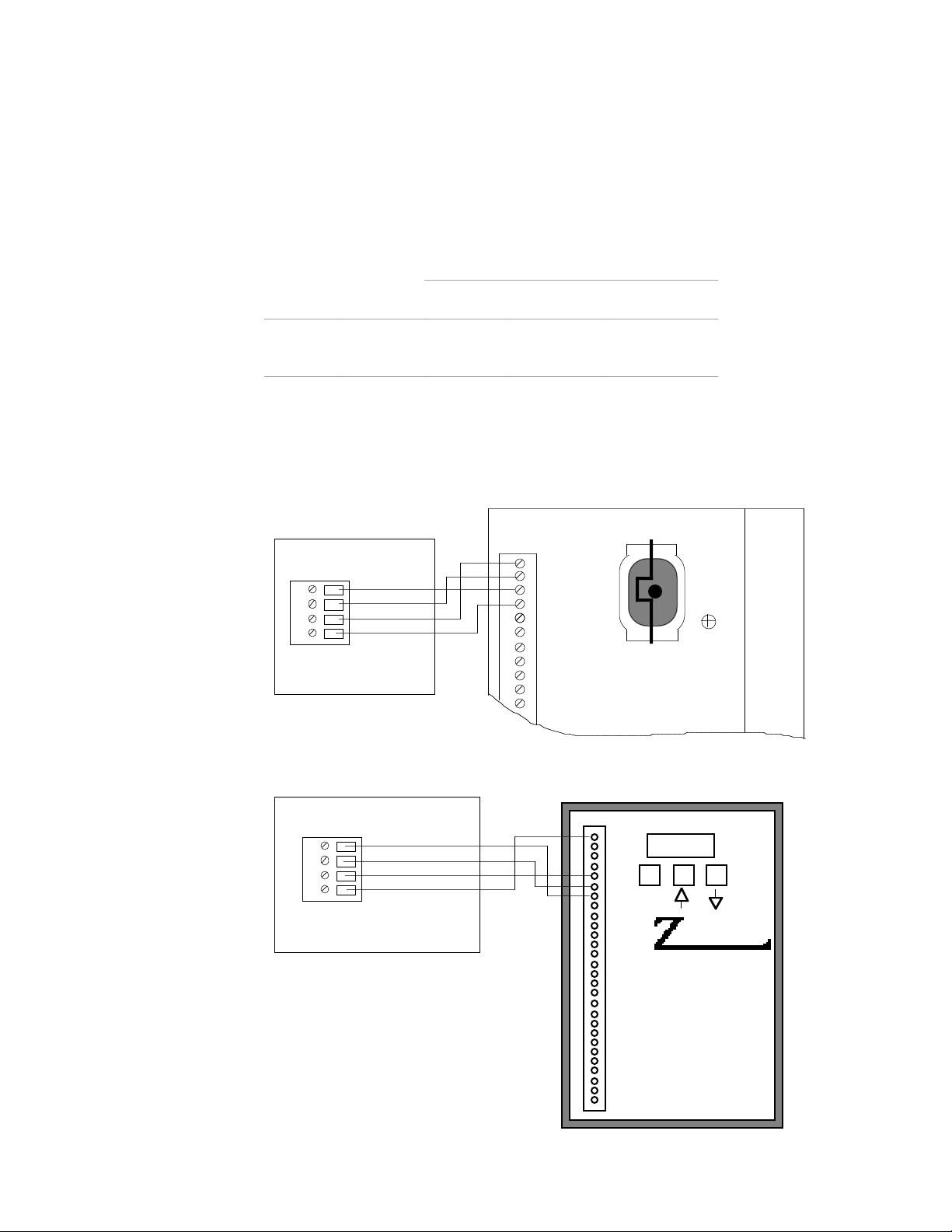

The RP240 is designed to operate as an operator interface for Compumotor's

Extended X (the SX Indexer/Drive, ZX Indexer/Drive, and Model 500 Indexer)

and 6000 Series products (6200 Indexer and 6250 Servo Controller). The

RP240 operates strictly as a dumb terminal. No programming of any kind

can be accomplished using the RP240. The RP240 is controlled by commands

available in the Extended X and 6000 Series command sets. The commands

allow the programmer to create a program (within the Extended X or 6000

Series product) to prompt an operator for numeric information, read

function keys, display variables and text, and control the 8 LEDs located on

the RP240.

If the RP240 is not used with the SX, ZX, Model 500, 6200, or 6250, ASCII

command strings sent directly to the RP240 can be used to control the

functions contained within the RP240 (refer to Chapter ➅Direct Control of

the RP240).

RP240 Features

❏Operates directly with Compumotor's SX and ZX Indexer/Drives, and the Model

500 Indexer

❏Operates directly with Compumotor's stand-alone 6000 Series products (6200

and 6250)

❏Can be used with any controller capable of transmitting ASCII strings across

RS-232C

❏Screw terminal connections for easy wiring

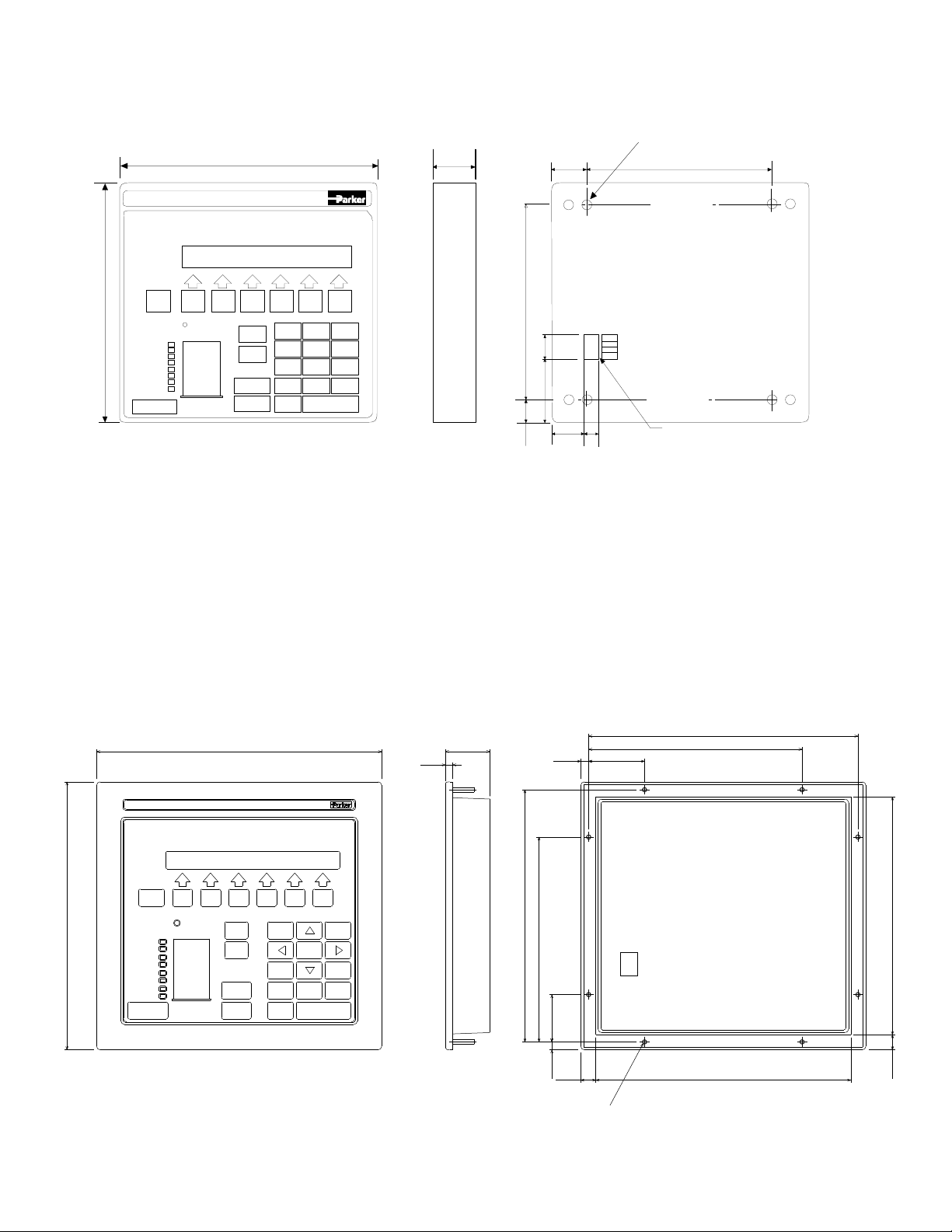

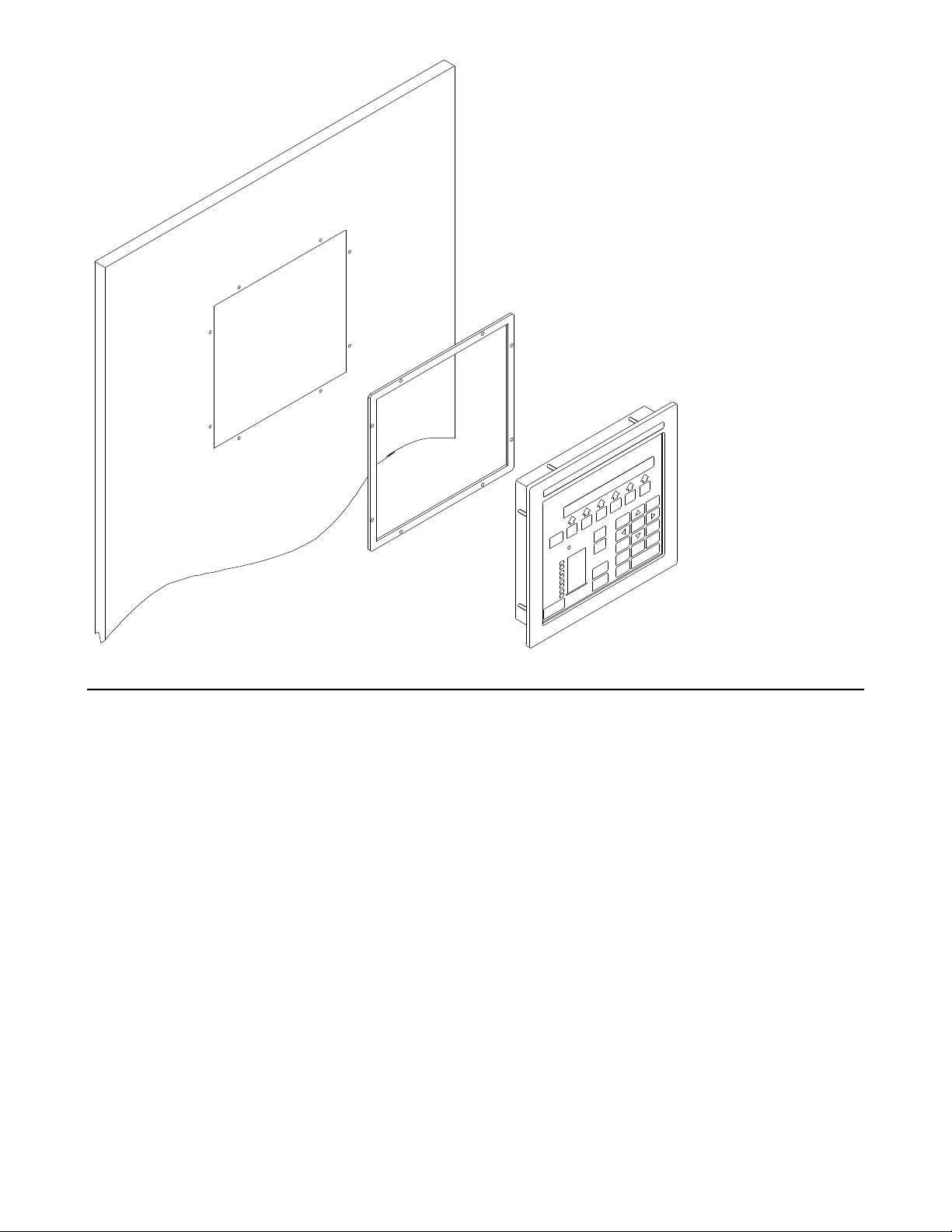

❏Optional NEMA specification ratings (standard RP240 is NEMA 12, optional

RP240-NEMA4 meets NEMA 4 & NEMA 12 specifications when panel mounted.)

❏Adjustable contrast for the LCD display

❏Eight independent LEDs

❏Numeric and function key data entry

❏Uses less than 100 mA of current at 5VDC