Chapter Page

1 Introduction, Designated Use ........................................................................................ 1-1

1.1 Fundamentals ................................................................................................................... 1-1

1.2 Target groups.................................................................................................................... 1-2

1.3 Designated use ................................................................................................................. 1-2

2 Safe Operation, Pollution Control.................................................................................. 2-0

2.1 General remarks ............................................................................................................... 2-0

2.2 Definition of terms ............................................................................................................. 2-1

2.3 Operational safety instructions..........................................................................................2-3

2.3.1 Safety signs at the site ..................................................................................................... 2-3

2.3.2 Recommended working area ...........................................................................................2-3

2.3.3 Noise emissions ............................................................................................................... 2-4

2.4 To be observed ................................................................................................................. 2-5

2.4.1 Prior to switching-on or restoring of power....................................................................... 2-5

2.4.2 During operation............................................................................................................... 2-5

2.4.3 In case of maintenance and repair ................................................................................... 2-7

2.5 Emergency measures .......................................................................................................2-8

2.6 Operating and waste materials.......................................................................................... 2-8

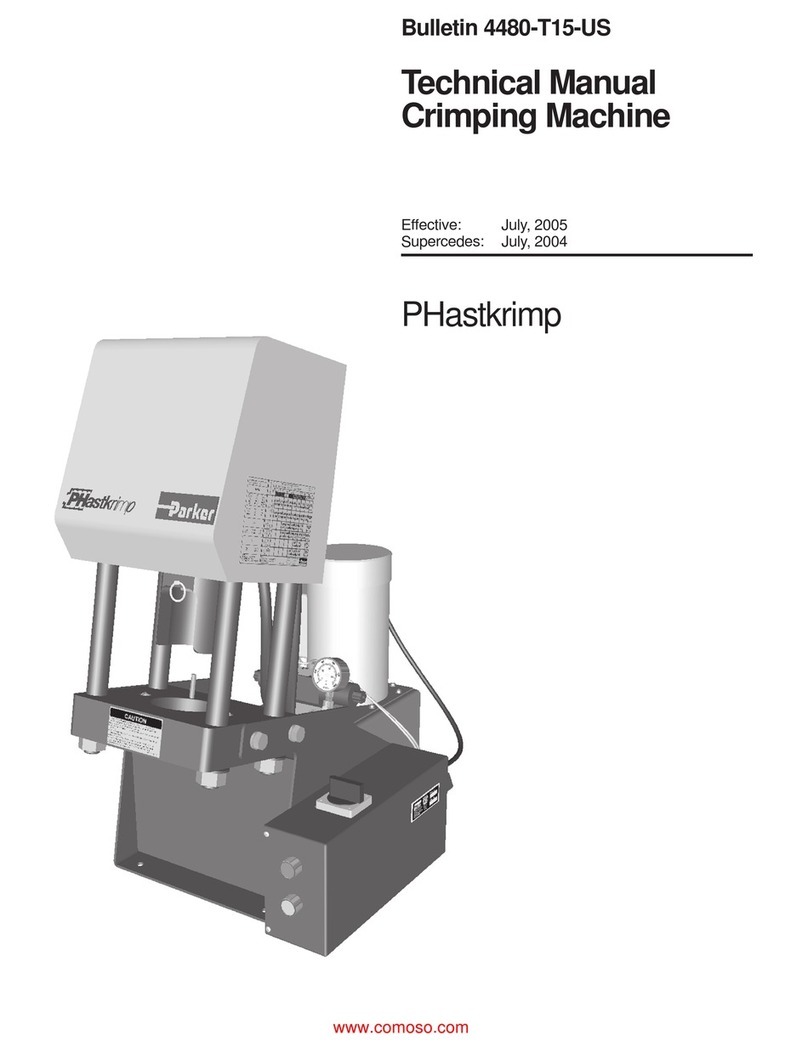

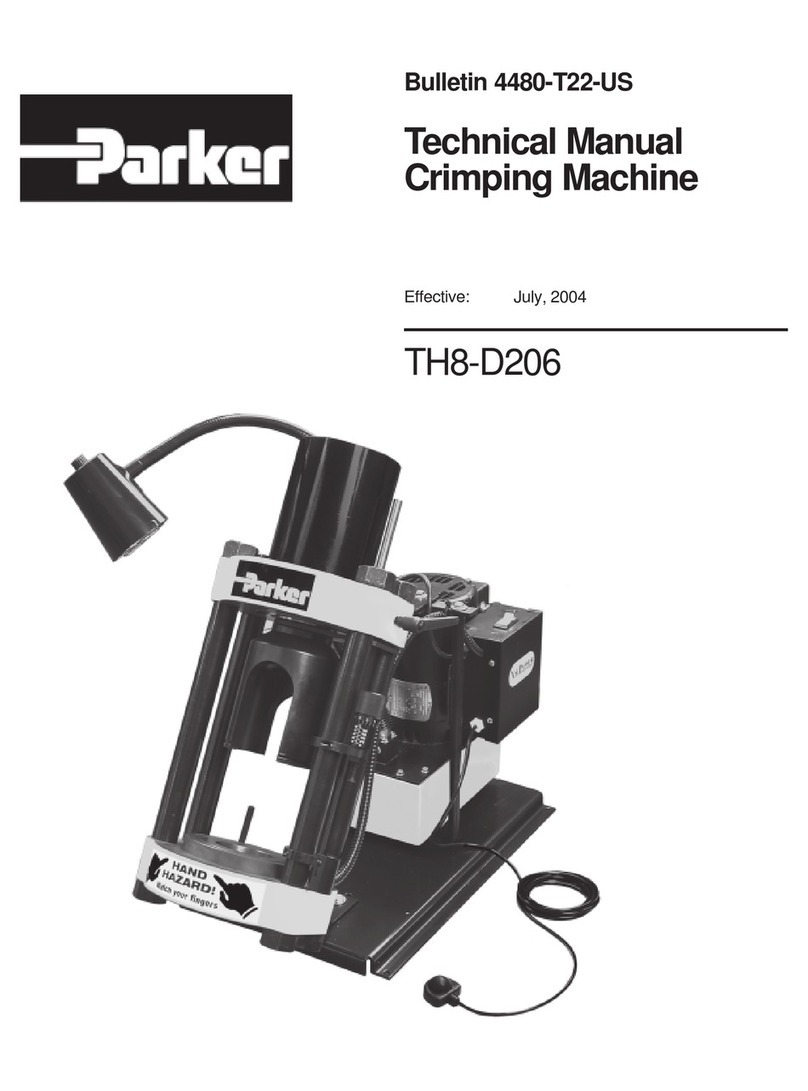

3 Construction and Function ............................................................................................ 3-1

3.1 Construction ...................................................................................................................... 3-1

3.2 Function ............................................................................................................................ 3-2

3.2.1 Assembly instructions....................................................................................................... 3-4

4 Transport, Dimensions, Installation, Intermediate Storage ........................................ 4-0

4.1 Transport........................................................................................................................... 4-0

4.1.1 Weights ............................................................................................................................ 4-0

4.2 Dimensions ....................................................................................................................... 4-0

4.3 Installation ......................................................................................................................... 4-1

4.3.1 Structural requirements .................................................................................................... 4-1

4.3.2 Energy required................................................................................................................ 4-1

4.3.3 Ambient conditions ........................................................................................................... 4-1

4.4 Intermediate storage of the plant....................................................................................... 4-2

4.5 Installation ......................................................................................................................... 4-2

5 Operation ......................................................................................................................... 5-1

5.1 First commissioning .......................................................................................................... 5-1

5.2 Switching-on...................................................................................................................... 5-2

5.3 Switching-off...................................................................................................................... 5-2

5.4 Restoring of power ............................................................................................................ 5-2

5.5 Operating mode ................................................................................................................ 5-3

5.6 Emergency stop ................................................................................................................ 5-4

Contents