Parker Hannifin Corporation

Hose Products Division

Wickliffe, OH

8

Crimping Machine

PHastkrimp

Bulletin 4480-T15-US

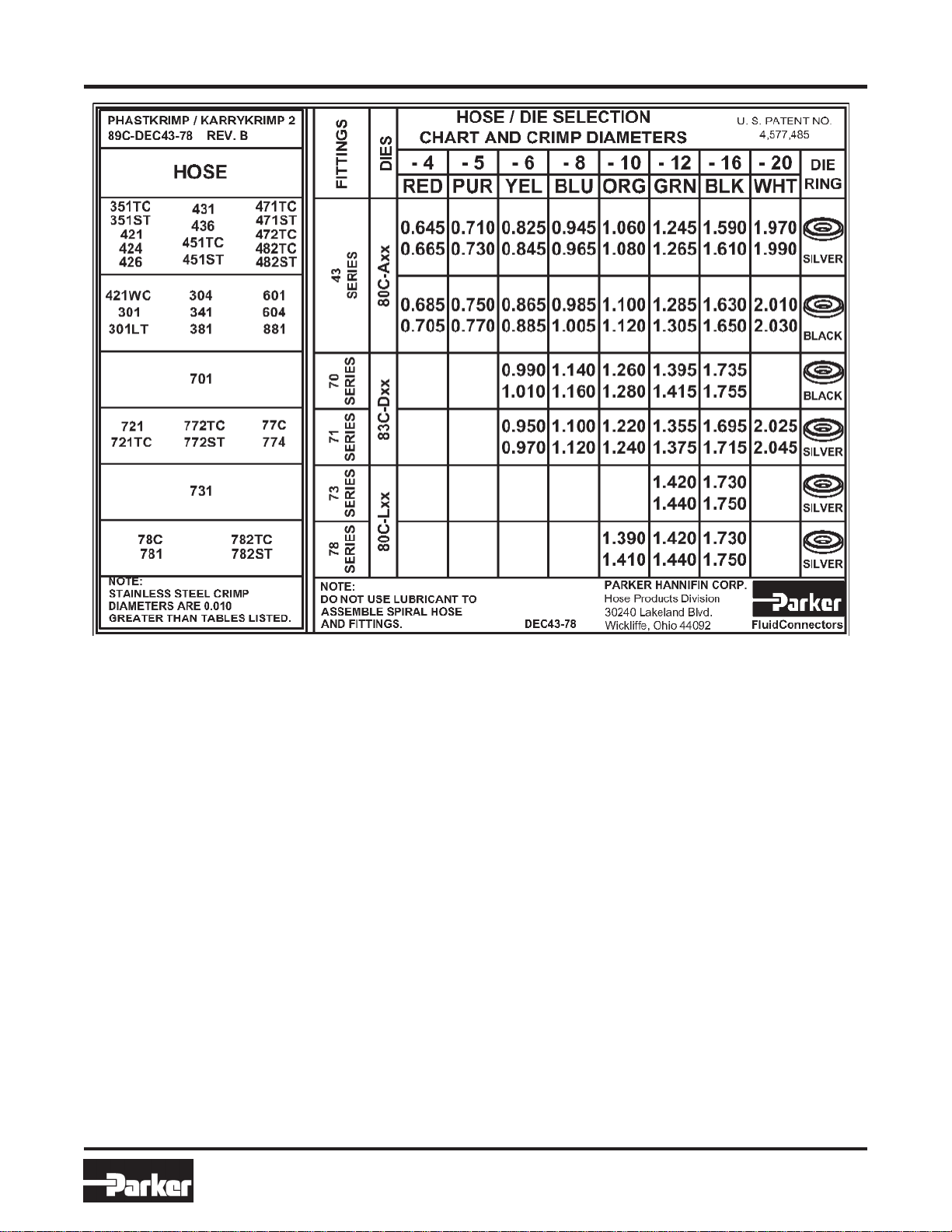

The following crimping dies are available for use with the PHastkrimp machine:

73 & 78 Series Fittings Dies (Olive Drab)

80C-L12 Size -12 (3/4") Color Coded Green

80C-L16 Size -16 (1") Color Coded Black

26 Series Fitting Dies (Silver)

80C-E04 Size -4 (3/16") Color Coded Red

80C-E05 Size -5 (1/4") Color Coded Purple

80C-E06 Size -6 (5/16") Color Coded Yellow

80C-E08 Size -8 (13/32") Color Coded Blue

80C-E10 Size -10 (1/2") Color Coded Orange

80C-E12 Size -12 (5/8") Color Coded Green

80C-E16 Size -16 (7/8") Color Coded Black

70 & 71 Series Fitting Dies (Black)

83C-D06 Size -6 (3/8") Color Coded Yellow

83C-D08 Size -8 (1/2") Color Coded Blue

83C-D10 Size -10 (5/8") Color Coded Orange

83C-D12 Size -12 (3/4") Color Coded Green

83C-D16 Size -16 (1") Color Coded Black

83C-D20 Size -20 (1-1/4") Color Coded White

43 Series Fitting Dies (Silver)

80C-A04 Size -4 (1/4") Color Coded Red

80C-A05 Size -5 (5/16") Color Coded Purple

80C-A06 Size -6 (3/8") Color Coded Yellow

80C-A08 Size -8 (1/2") Color Coded Blue

80C-A10 Size -10 (5/8") Color Coded Orange

80C-A12 Size -12 (3/4") Color Coded Green

80C-A16 Size -16 (1") Color Coded Black

80C-A20 Size -20 (1-1/4") Color Coded White

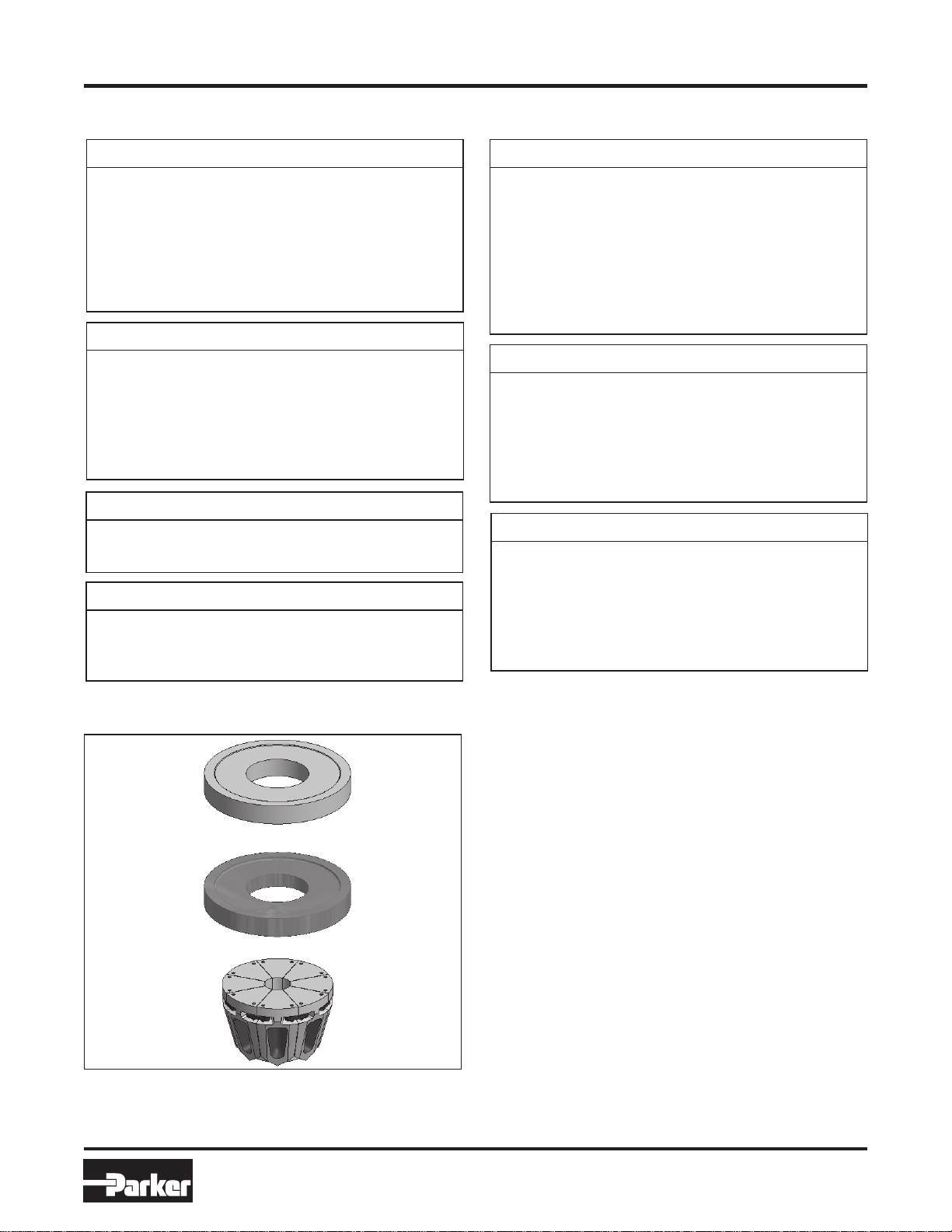

Silver

Die Ring

Black

Die Ring

Die Set

Figure 10: Die Rings and Die Set

81 Series Fittings Dies (Silver)

80C-V12 Size -12 (3/4") Color Coded Green

80C-V16 Size -16 (1") Color Coded Black

80C-V20 Size -20 (1-1/4”) Color Coded White

Operations and Crimping

HY Series Fitting Dies for AX hose (Silver)

80C-H585 Size -4 (1/4") Color Coded Brown

80C-H735 Size -6 (3/8") Color Coded Brown

80C-H840 Size -8 (1/2") Color Coded Brown

80C-H970 Size -10 (5/8") Color Coded Brown

80C-H1120 Size -12 (3/4") Color Coded Brown

80C-H1365 Size -16 (1") Color Coded Brown

HY Series Fitting Dies for BXX hose (Silver)

80C-H605 Size -4 (1/4") Color Coded Brown

80C-H775 Size -6 (3/8") Color Coded Brown

80C-H885 Size -8 (1/2") Color Coded Brown

80C-H1010 Size -10 (5/8") Color Coded Brown

80C-H1170 Size -12 (3/4") Color Coded Brown

80C-H1465 Size -16 (1") Color Coded Brown

The PHastkrimp Model 89C-061/062 is shipped without

dies.

The 43 Series dies are silver and inserts are color coded

by size. Refer to the die selection chart above, Parker

Catalog 4400 or CrimpSource online, at

www.parkerhose.com to determine which die set and die

ring to use when crimping a particular fitting, hose size

andtype.

The following tooling is used for crimping:

85C-R01 Silver Die Ring

To determine when to use, refer to die selection chart in

Parker Catalog 4400 or decal on side of crimper.

85C-R02 Black Die Ring

To determine when to use, refer to die selection chart in

Parker Catalog 4400 or decal on side of crimper.

See above for die set part numbers.

www.comoso.com