Bulletin 1531-001/USA Pump/Motor Division

700 Series Service Procedure

Parker Hannin Corporation

Hydraulic Pump/Motor Division

Greeneville, TN 37745 USA

5

Preliminary Checks

Hydraulic systems are often trouble-free. Hence, the

problem an operator complains of could be caused by

something other than the hydraulic components.

Thus, once you have determined that a problem ex-

ists, start with the easy-to-check items, such as:

• Parts damaged from impact that were not

properly repaired, or that should have been

replaced

• Improper replacement parts used in previous

servicing

• Mechanical linkage problems such as bind-

ing, broken or loose parts, or slipping belts

Hydraulic Components

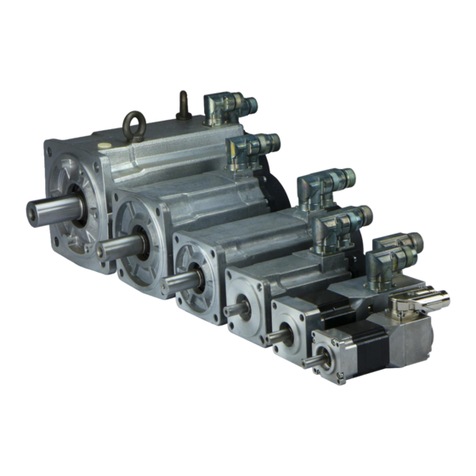

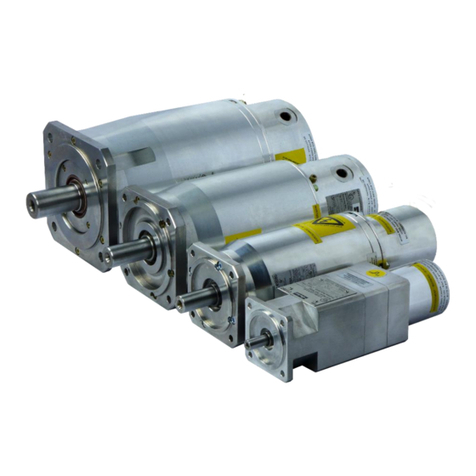

If the motor has low speed or torque, look at the check

list on the next page rst. Since these motors maintain

volumetric and torque efciencies during their usual

life, the problem is usually elsewhere in the hydraulic

system.

However, there are hydraulic system problems which

can drastically reduce the long life designed into these

motors. Three key areas to check are:

• Temperature: Do not exceed 180˚F.

• Fluid: Viscosity at the maximum temperature

must exceed 50 ssu.

• Filtration: A Beta 25 ratio of at least 2.

Troubleshooting Guide

Preparation

Make your troubleshooting easier by preparing as fol-

lows:

• work in a clean, well-lighted place

• have proper tools and materials nearby

• have an adequate supply of clean, petro-

leum-based solvent

• prior to any motor disassembly, plug the

open ports and case drain

• clean all dirt from outside the motor

• prior to assembly, lightly oil all seals, rollers,

rolls and the threaded bolt ends

Since solvents are ammable, be

extremely careful when using any

solvent. Even a small explosion

could cause injury or death.

Wear eye protection and be sure

to comply with OSHA and other

maximum air pressure require-

ments.

WARNING

WARNING

NOTE Before troubleshooting any system prob-

lem, check service literature published

by the equipment and/or component

manufacturers. Follow their instructions, if

given, for checking any component other

than the motor unit.