4 5

GENERAL SAFETY

• Disconnect the drill from the battery unit before changing

accessories, servicing or performing any maintenance.

• Maintain the drill and battery in good condition. Check

moving parts alignment on a regular basis.

• Replace or repair damaged parts. Unauthorised parts may be

dangerous and will invalidate the warranty.

• Ensure the drill is switched o before installing the battery

pack.

• Keep the drill and charger clean.

• Remove baggy clothing, watches, ties, rings and other loose

jewellery.

• Ensure long hair is secured and not in the way while

operating the product.

• Evaluate your working area before using the product.

• Secure loose work pieces with a clamp, vice or similar

holding device.

• Avoid unintentional starting.

• Wear approved safety eye protection (standard spectacles

are not suicient)

• Maintain correct balance and footing. Ensure the floor is not

slippery and wear non-skid shoes.

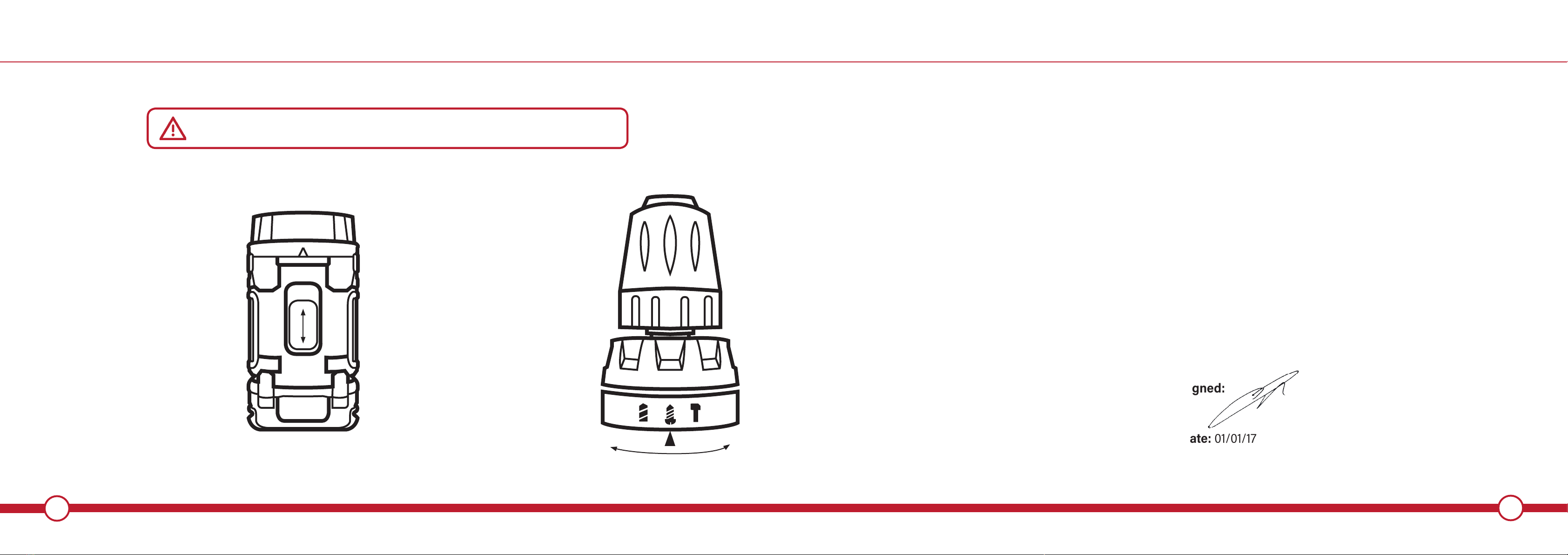

• Keep chuck direction switch in the locked position until the

drill is required for use.

• Keep children and unauthorised persons away from the

working area.

• Keep drill and charger in case and store in a safe, dry, child-

proof area where the temperature will not exceed 104ºF /

40ºC

• DO NOT use the drill where there are flammable liquid, solids

or gases, such as petroleum etc.

• DO NOT allow children to operate the drill.

• DO NOT operate the drill if any parts are missing as this may

cause failure and/or personal injury.

• DO NOT leave the drill operating unattended.

• DO NOT carry the drill with your finger on the power switch.

• DO NOT use the drill for a task it is not designed to perform.

• DO NOT operate the drill when you are tired or under the

influence of alcohol, drugs or any intoxicating medication.

• DO NOT get the drill or battery charger wet

• DO NOT use the drill in damp or wet locations.

BATTERY SAFETY

• Charge battery prior to first use. The battery pack is shipped

in a low charge state.

• Use only the charger provided to charge the drill battery.

• Do not attempt recharging the battery by means of an engine

generator or a DC power source.

• Do not short-circuit the battery by linking both terminals with

a metal object, or your fingers etc.

• Do not store the battery or drill in locations where the tem-

perature may exceed 104ºF / 40ºC.

• WARNING! Dispose of spent batteries correctly.

• DANGER! Do not attempt to dismantle the battery pack.

For safety and environmental reasons do not discard in

domestic waste or by burning. Only discard or recycle

according to local authority regulations.

• WARNING! Do not allow a leaking battery to contact your

body. If you come into contact with battery liquid take the

following actions immediately:

a) Skin contact: Wash immediately with soap and water, then

wash flesh in either lemon juice or vinegar.

b) Eye contact: Wash with a strong solution of boric acid, and

seek immediate medical attention.

• WARNING! DO NOT use the charger to charge any battery

other than that supplied for the drill. Other types of batteries

may explode.

• All mains electrical supply safety features must be followed

as described.

• Disconnect the charger from the mains power supply when

not in use.

• DO NOT operate the charger if it has been dropped, or has

received a sharp knock, or is damaged.

• DO NOT insert foreign objects or material into the hole

reserved for the battery.

• DO NOT force the battery into the charger. The battery will

only fit one way to ensure correct polarity alignment.

• DO NOT charge a second battery immediately. Consecutive

charging will overheat the charger. Allow the unit to cool

15 minutes before charging the next battery.

• DO NOT attempt to connect two chargers together.