Parker Hannifin S.p.A. S.B.C. Division user’s manual PSU

3

1. PSU (POWER SUPPLY UNIT) ............................................................................... 4

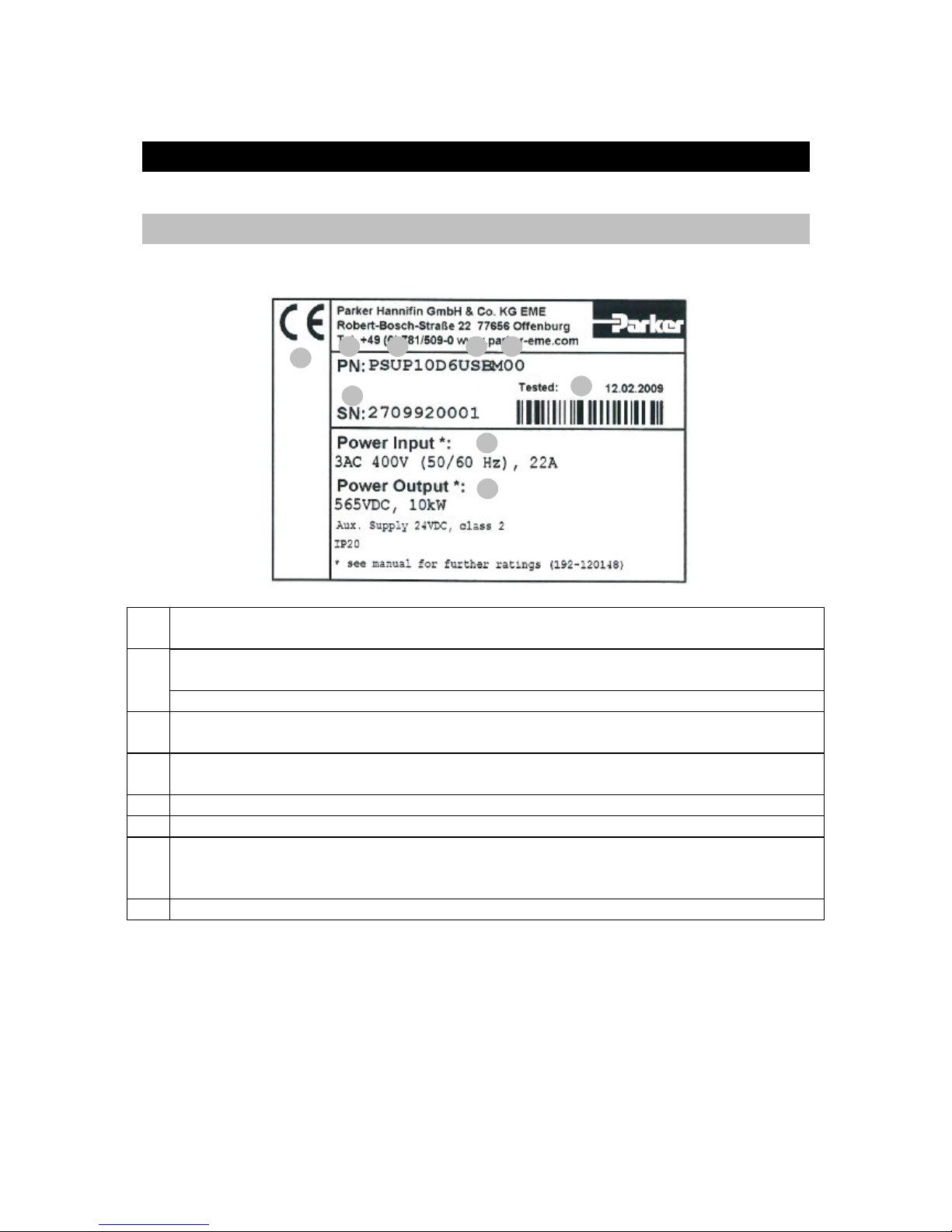

1.1.Identfication ............................................................................................................... 4

1.2.Condition of utilization .............................................................................................. 5

1.2.1.Filters .................................................................................................................. 5

1.2.2.Cable ................................................................................................................... 5

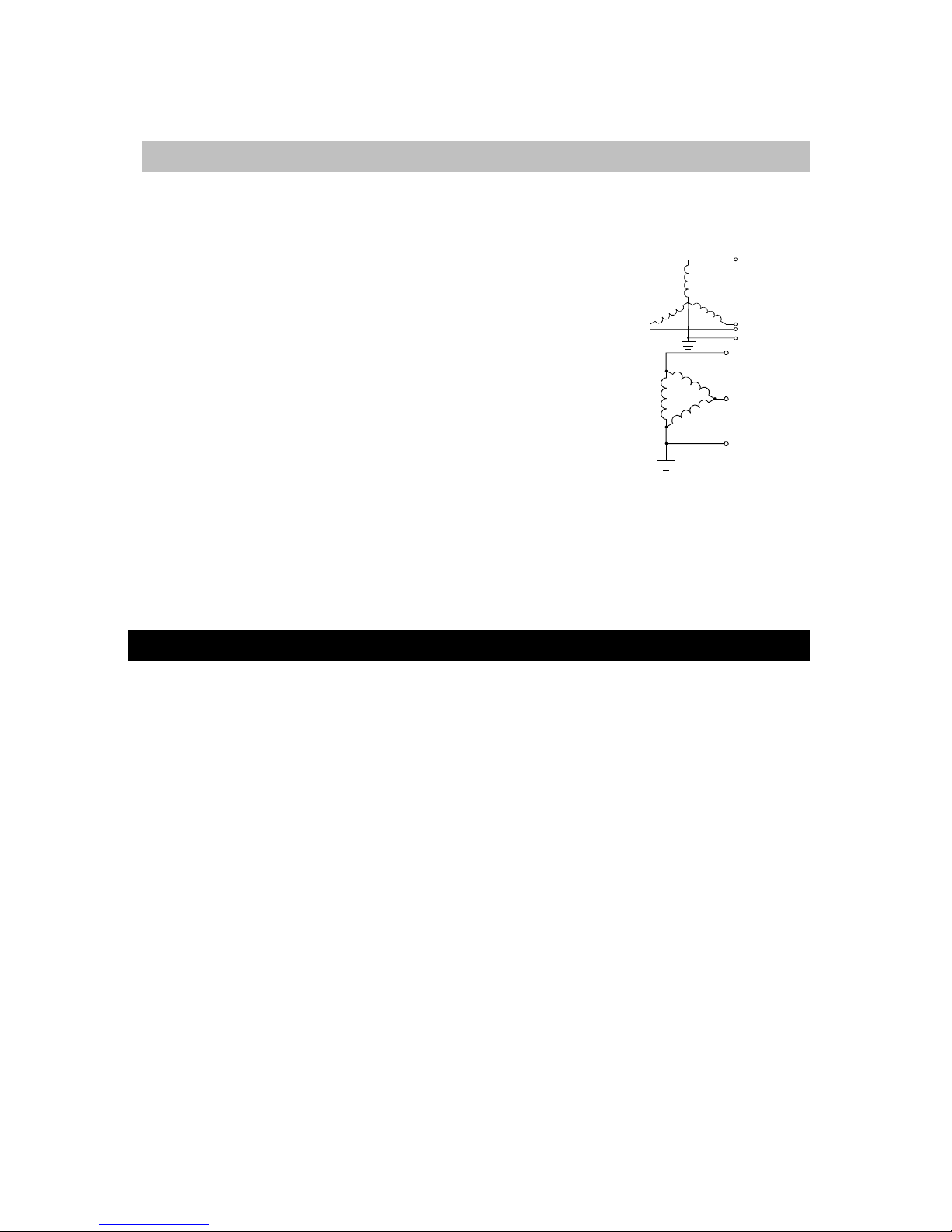

1.2.3.Grounding ........................................................................................................... 5

1.2.4.PSU protections .................................................................................................. 5

1.2.5.Hardware PSU .................................................................................................... 6

2. MOUNTING ............................................................................................................ 7

2.1.Connectors layout ....................................................................................................... 8

2.1.1.LED Status ......................................................................................................... 8

2.1.2.Signal connectors ............................................................................................... 8

3. MODULE CONNECTIONS ..................................................................................... 9

3.1.1.Rail system ......................................................................................................... 9

3.1.2.Communication connection ................................................................................ 9

3.2.Mains supply ............................................................................................................ 10

4. PARAMETERS SET-UP ...................................................................................... 10

4.1.1.Voltage supply .................................................................................................. 10

5. REVISION HISTORY OF THE USER MANUAL .................................................. 11