Introduction

Follow these instructions when installing, operating, or servicing the

product.

Isysnet 24VDC Expansion Power Supply,

Series A

(PSSSE24A)

The 24VDC expansion power supply unit (PSSSE24A) passes 24VDC

field power to the I/O modules to the right of the power supply. This

unit extends the backplane bus power for up to 17 I/O modules to the

right of the supply and creates a new field voltage partition.

The expansion power supply also separates field power from I/O

modules to the left of the unit, effectively providing functional and

logical partitioning for:

• separating field power between input and output modules

• separating field power to the analog and digital modules

• grouping modules to perform a specific task or function

You can use multiple expansion power units with the I/O adapters

to assemble a full system. For instance, if you are using the

PSSCDM12A or PSSCDM18PA adapter, you may use a PSSSE24A

expansion power unit to add additional modules in 5 to 17 module

increments. For example, if you had a 36 module system with a I/O

adapter, you would have two PSSSE24A expansion power units

to provide more PointBus current for modules to the right of the

supply.

Installation & Service Instructions

E105P

Isysnet 24VDC Expansion Power

Supply, Series A (PSSSE24A)

ISSUED: January, 2007

Supersedes: June, 2005

Doc.# E105P, ECN# 060961, Rev. 2

Do not connect 120/240VAC to the PSSSE24A terminals.

Damage to the supply will result.

ATTENTION

You can only use the PSSSE24A expansion power unit with

the I/O adapters.

ATTENTION

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER USE OF THE

PRODUCTS AND/OR SYSTEMS DESCRIBED HEREIN OR RELATED

ITEMS CAN CAUSE DEATH, PERSONAL INJURY AND PROPERTY

DAMAGE.

This document and other information from Parker Hannifin Corporation,

its subsidiaries and authorized distributors provide product and/or system

options for further investigation by users having technical expertise. It

is important that you analyze all aspects of your application, including

consequences of any failure and review the information concerning the

product or systems in the current product catalog. Due to the variety of

operating conditions and applications for these products or systems, the

user, through its own analysis and testing, is solely responsible for making

the final selection of the products and systems and assuring that all

performance, safety and warning requirements of the application are met.

The products described herein, including without limitation, product

features, specifications, designs, availability and pricing, are subject to

change by Parker Hannifin Corporation and its subsidiaries at any time

without notice.

EXTRA COPIES OFTHESE INSTRUCTIONS ARE AVAILABLE FOR INCLUSION

IN EQUIPMENT / MAINTENANCE MANUALSTHAT UTILIZETHESE PRODUCTS.

CONTACT YOUR LOCAL REPRESENTATIVE.

Pneumatic Division

Richland, Michigan 49083

Safety Guide

For more complete information on recommended application guidelines, see

the Safety Guide section of Pneumatic Division catalogs or you can download

the Pneumatic Division Safety Guide at: www.parker.com/safety

WARNING

• To avoid unpredictable system behavior that can cause personal

injury and property damage:

• Disconnect electrical supply (when necessary) before installation,

servicing, or conversion.

• Disconnect air supply and depressurize all air lines connected to this

product before installation, servicing, or conversion.

• Operate within the manufacturer’s specified pressure, temperature,

and other conditions listed in these instructions.

• Medium must be moisture-free if ambient temperature is below

freezing.

• Service according to procedures listed in these instructions.

• Installation, service, and conversion of these products must be

performed by knowledgeable personnel who understand how

pneumatic products are to be applied.

• After installation, servicing, or conversion, air and electrical supplies

(when necessary) should be connected and the product tested for

proper function and leakage. If audible leakage is present, or the

product does not operate properly, do not put into use.

• Warnings and specifications on the product should not be covered by

paint, etc. If masking is not possible, contact your local representative

for replacement labels.

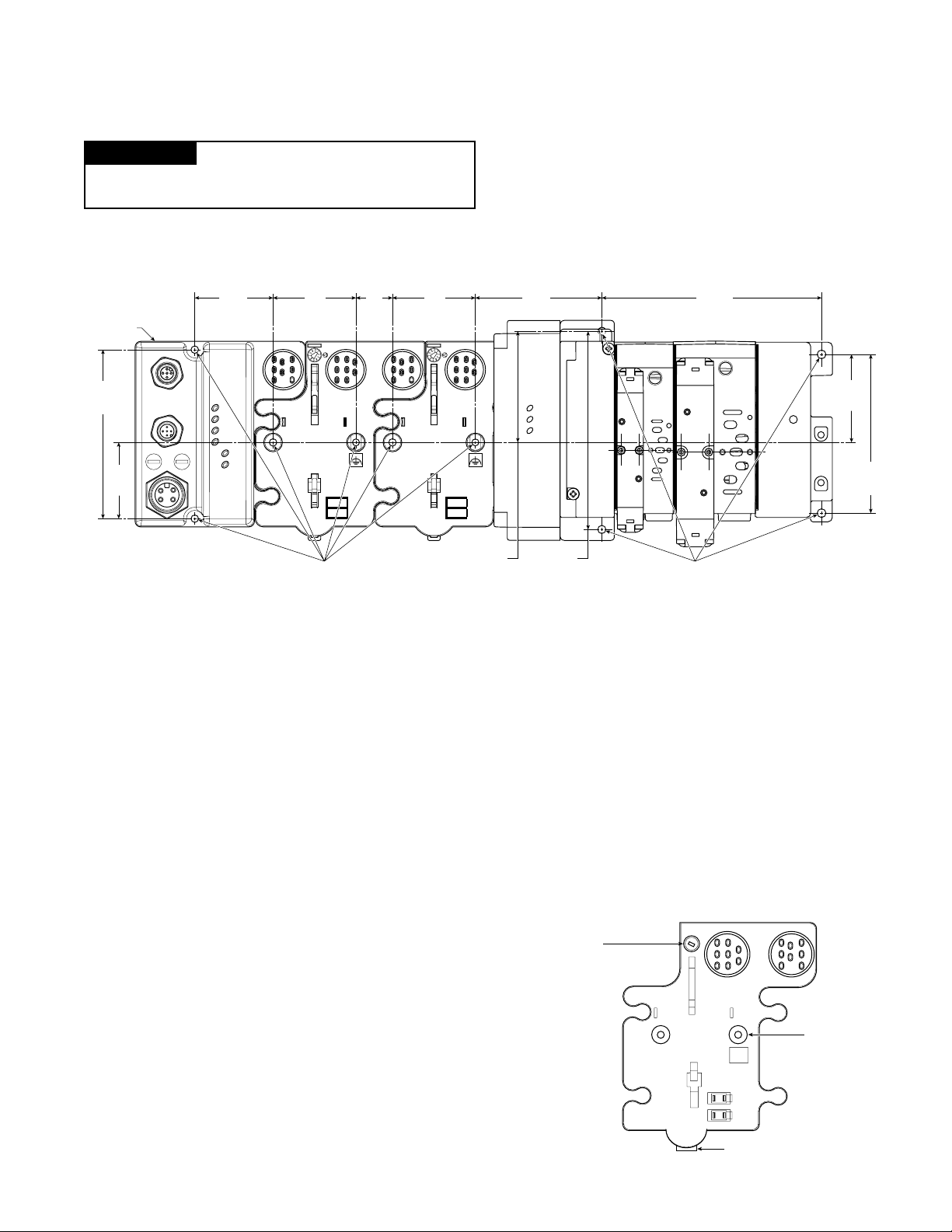

PSSSE24A

24V dc Power Supply

System

Power

Field

Power

A

U

X

P

O

W

E

R

PSSSE24A

24VDC

Expansion

Power Supply

Wire

Marker

Mini 7/8”

Power

Connector

LED

Indicators