6 GB

Introduction

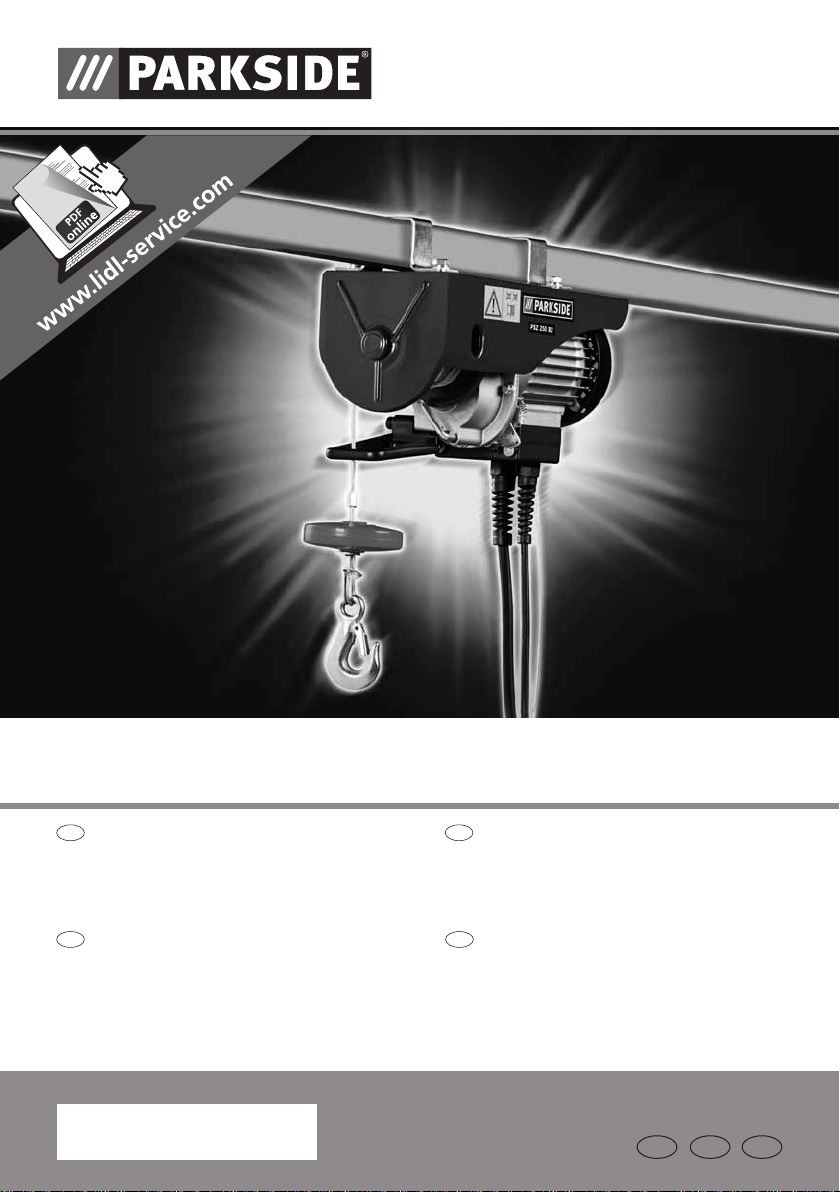

Cable winch PSZ 250 B2

Introduction

Please familiarise yourself with the appli-

ance before preparing it for use and using

it for the first time. To do so, please care-

fully read the following operating instructions and

the important safety information. Use the product

only as described and for the indicated purpose.

Keep these instructions in a safe place. If you pass

the device on to anyone else, please ensure that

you also pass on all the documentation.

The cable hoist is used to hoist and lower loads in

indoor spaces in accordance with the equipment

power. Only use the device as described. Any other

use is not intended. The user / operator, not the ma-

nufacturer, is liable for damages or any type of injury

resulting from any other use. Please note that our de-

vices were not constructed for commercial, manual,

or industrial use. We do not accept any warranty li-

ability if the device is used for commercial, manual,

or industrial operations, or activities similar to these.

Intended use

Scope of delivery

Technical Data

Parts description

1

2

4

6

8

10

11

12

13

15

14

16

3

5

7

9

Mounting bracket

Hoisting drum

Shut-off weight

Emergency stop switch

Remote control unit

Control lead

Deflection pulley

Maximum cable length lever

Auto-stop mechanism lever

Steel cable

Hook

Push button

Mains lead

Motor

Additional hook

1 Cable hoist

2 Mounting bracket with mounting materials (Fig. C)

1 Deflection pulley with additional hook and

mounting materials (see Fig. D)

1 Set of instructions for use

Duty type 3–20 % - 10 min: S3 = Intermittent duty

without the effect of starting. During a 10 min period

the max. operating time is 20 % (2 min).

Mechanical group M1.

The rated power of the device does not vary with

the position of the load.

The value of the A-rated noise emission in the

operator position is less than 70 dB.

The cable hoist must be operated at ambient tempe-

ratures from 0 °C to 40 °C and a relative humidity

below 85 %. Height above sea level: max. 1000 m.

Voltage: 230 V~50 Hz

Rated current: 2.2 A

Power input: 500 W

Duty type: S3 20 % 10 min

Rated load: 125 / 250 kg (without /

with deflection pulley)

Hoisting height: 11.5 / 5.7 m (without / with

deflection pulley)

Rated speed: 8 / 4 m / min (without / with

deflection pulley)

Steel cable

diameter: 3.0 mm

Steel cable

tensile strength: 1870 N / mm2

Insulating level: B

Degree of

protection: IP54

Power unit class: M1

Net weight: 9.3 kg

Gross weight: 10.5 kg

Mounting opening for hook in deflection

operation