1. INTRODUCTION

Customer Instruction

1. GENERAL

Encourage the customer to review instructional

material provided with the saw to achieve the best

performance and reliability; and to ensure safety

for himself and others.

2.

SAFETY

Follow standard safety procedures established for

any hand-held concrete saw. Discuss proper

operating pressure and proper oil flow. Instruct

customer on correct blade rotation.

3.

SAFETY EQUIPMENT

Go over all safety clothing and equipment that

must be used. Stress the importance of eye

protection.

4.

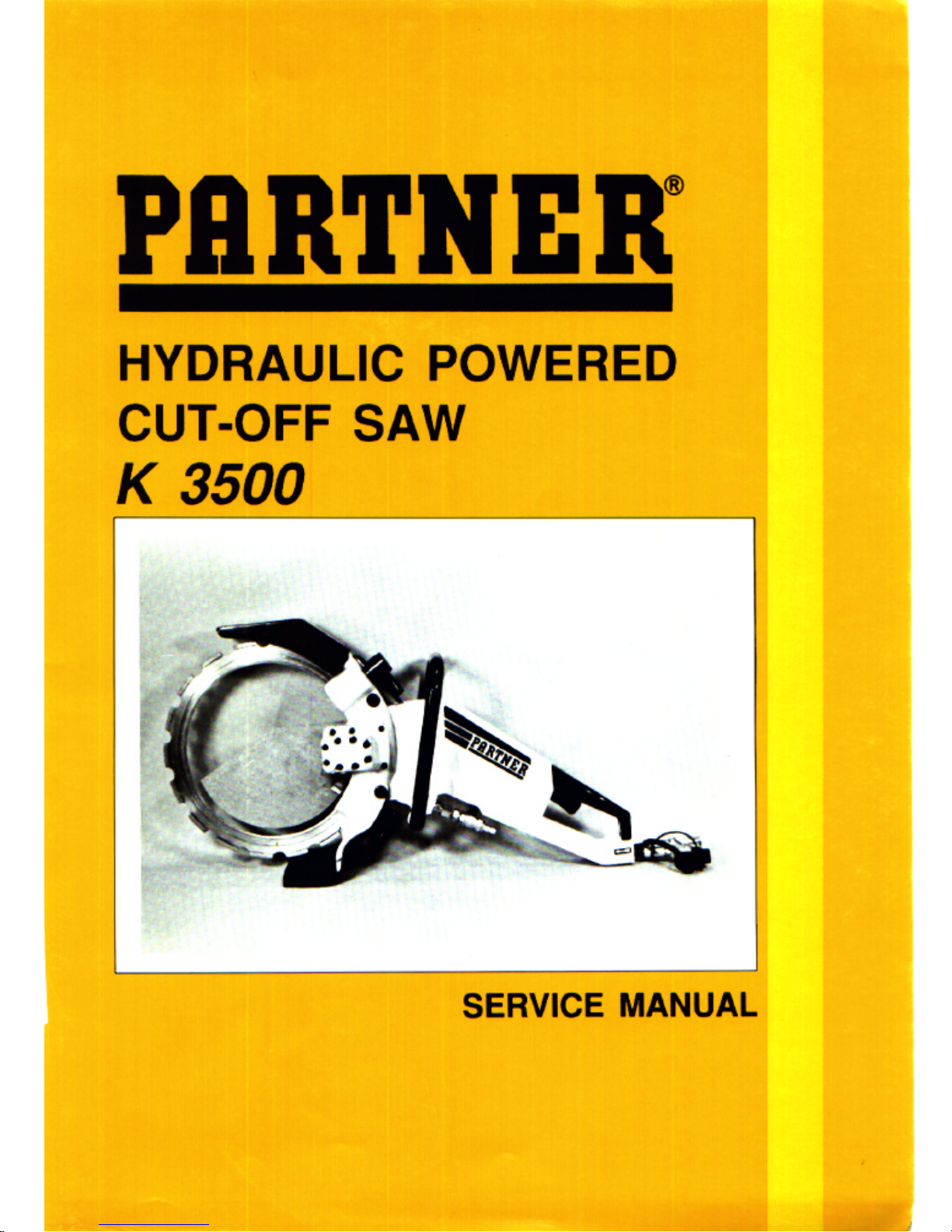

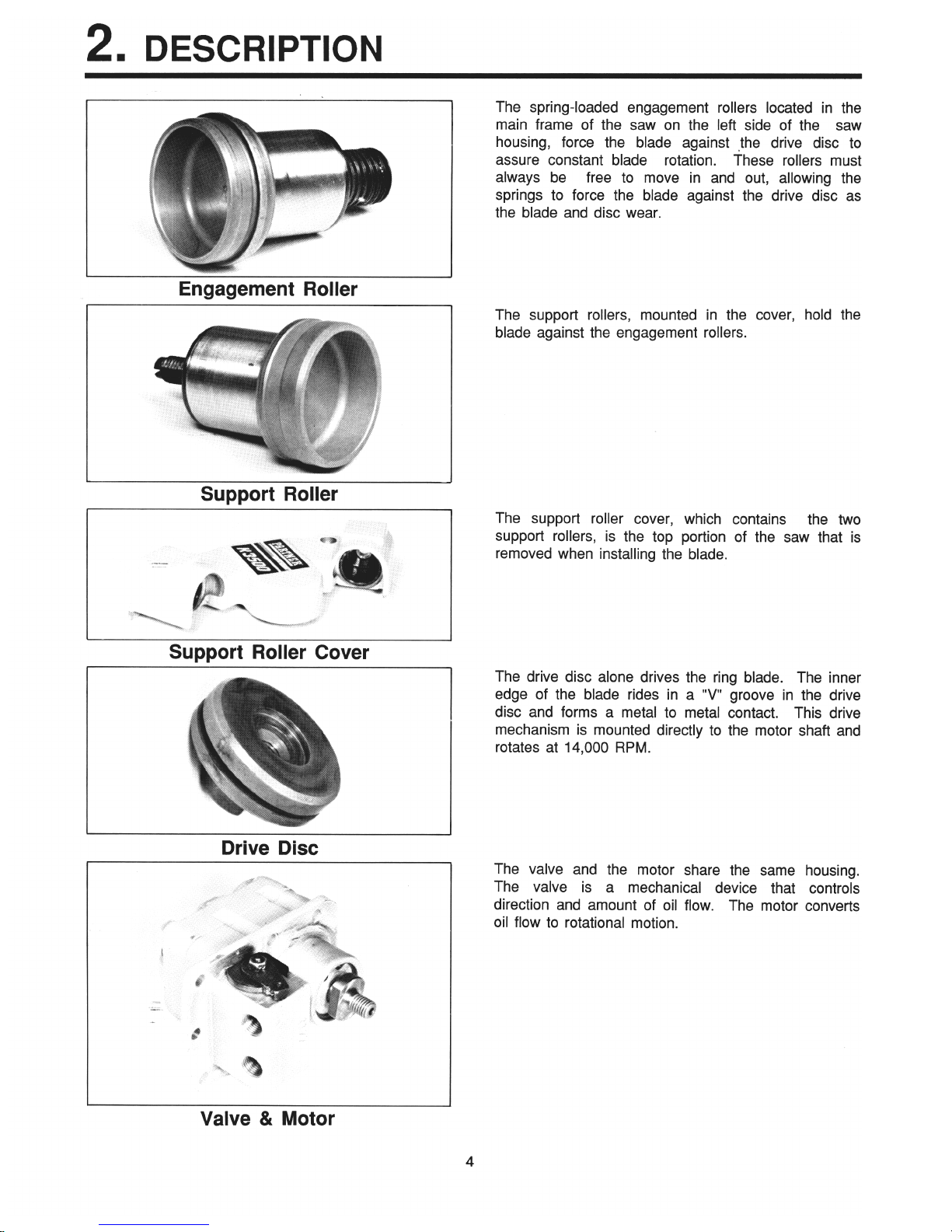

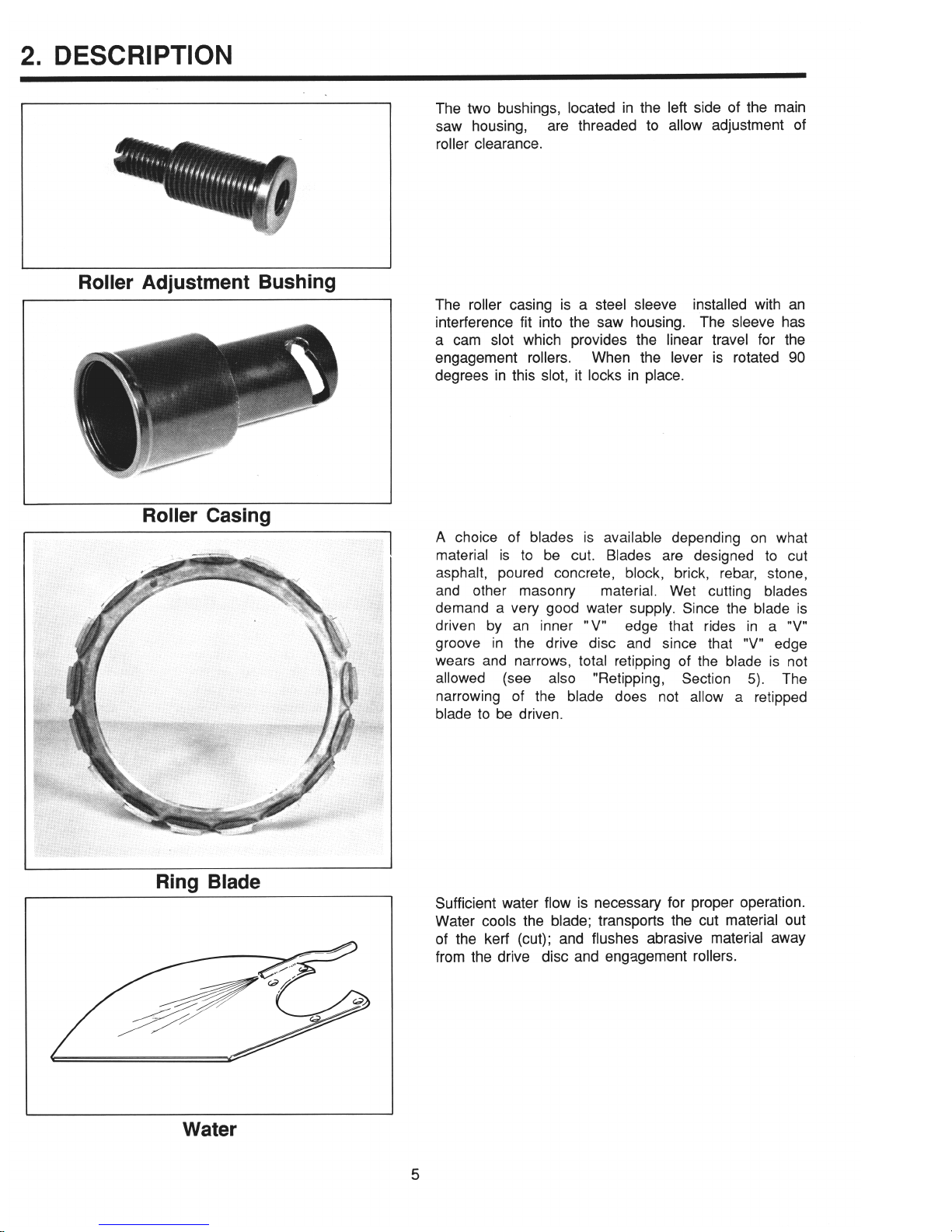

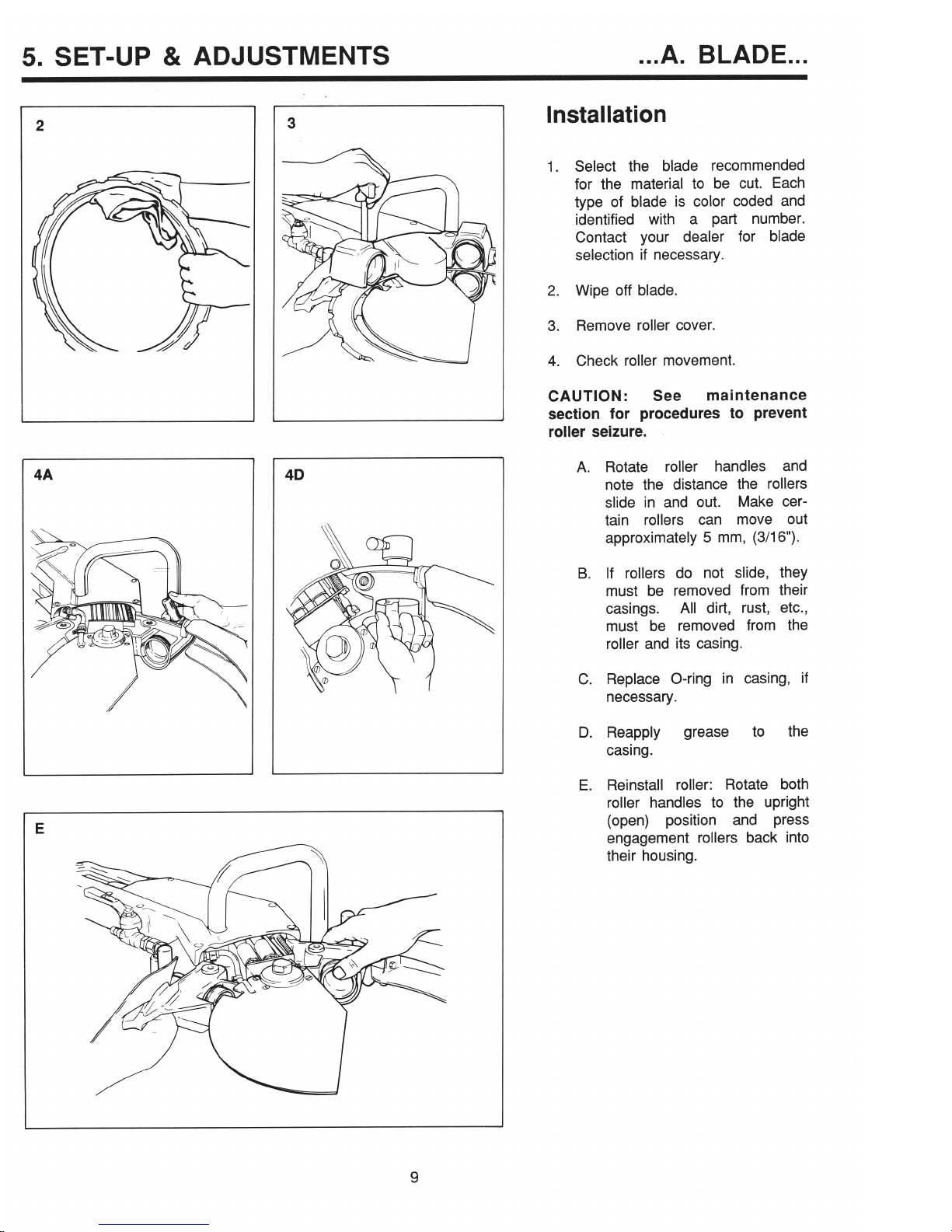

CUTTING BLADES, ROLLERS, AND

DRIVE DISC

Inform the customer about matching the blade

type to the type of material to be cut. Show how

to adjust the rollers. Give guidelines on what to

expect on roller life, drive disc life and blade life,

all of which vary with the operating technique and

the material being cut. Tell the customer, when

the blade slows or stops cutting, to first check the

condition of the drive disc before making other

adjustments. Advise him that blades are for wet

cutting, not dry cutting.

5. CONTROLS

Show the customer the correct starting position

and how the controls work when cutting. Stress

the importance of keeping all controls clean to

allow proper movement.

6.

WORKING TECHNIQUE

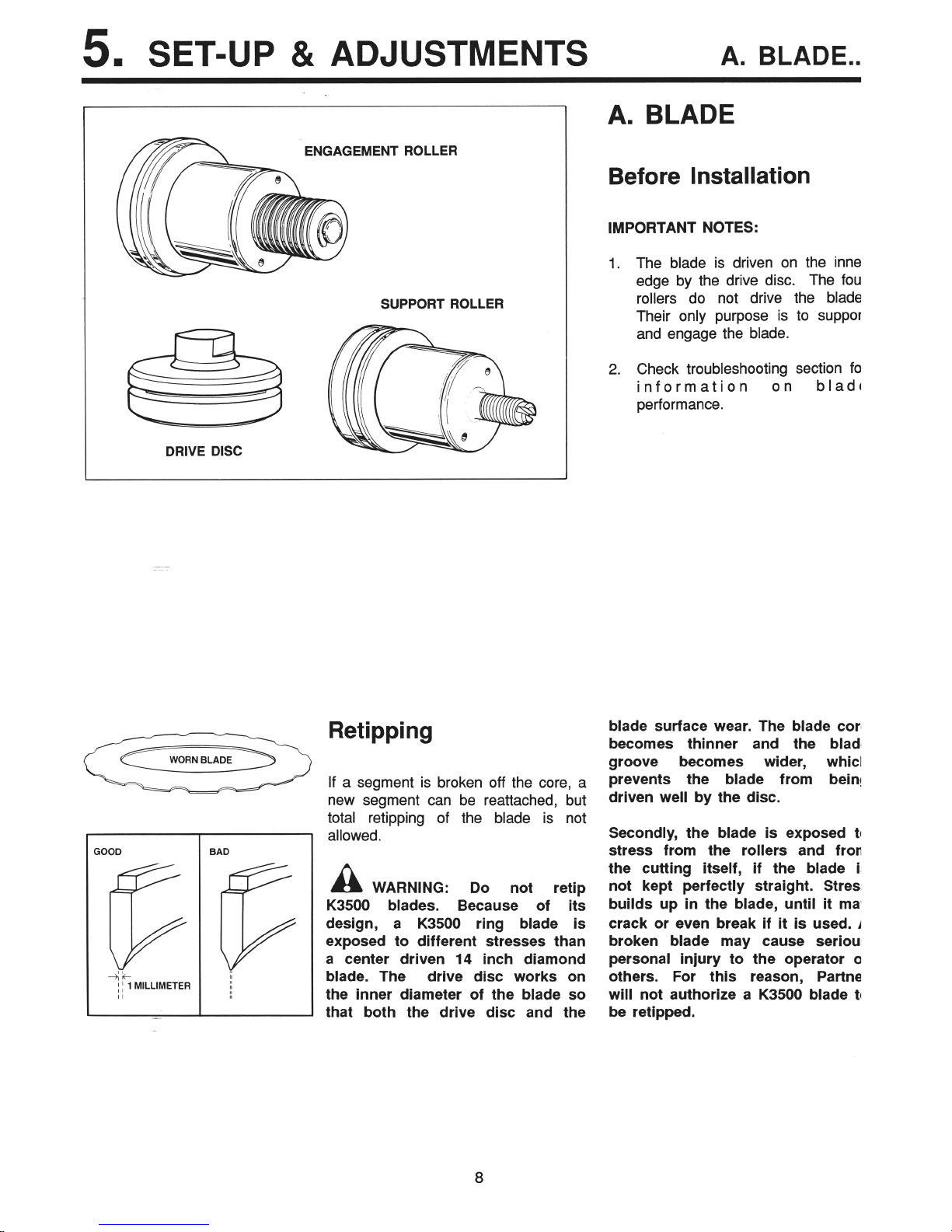

Demonstrate approved cutting techniques with

special emphasis on avoiding unsafe practices

such as twisting the blade in the cut. Emphasize

the importance of ample water supply on the

blade and of keeping all water nozzles free of

blockage.

7.

MAINTENANCE

Inform the customer about the maintenance which

he or the operator can perform. Stress the

importance of lubricating the engagement rollers

and checking the wear of the drive disc on a

regular basis to avoid unexpected blade slippage.

Follow maintenance schedule provided in the

Service Manual.

8. WARRANTY

Cover the information in the warranty and send in

the warranty registration card. The warranty

covers breakdown due to defective material or

workmanship for 6 months.

3