REPLACEMENT OF CHAIN/BAR 4

7

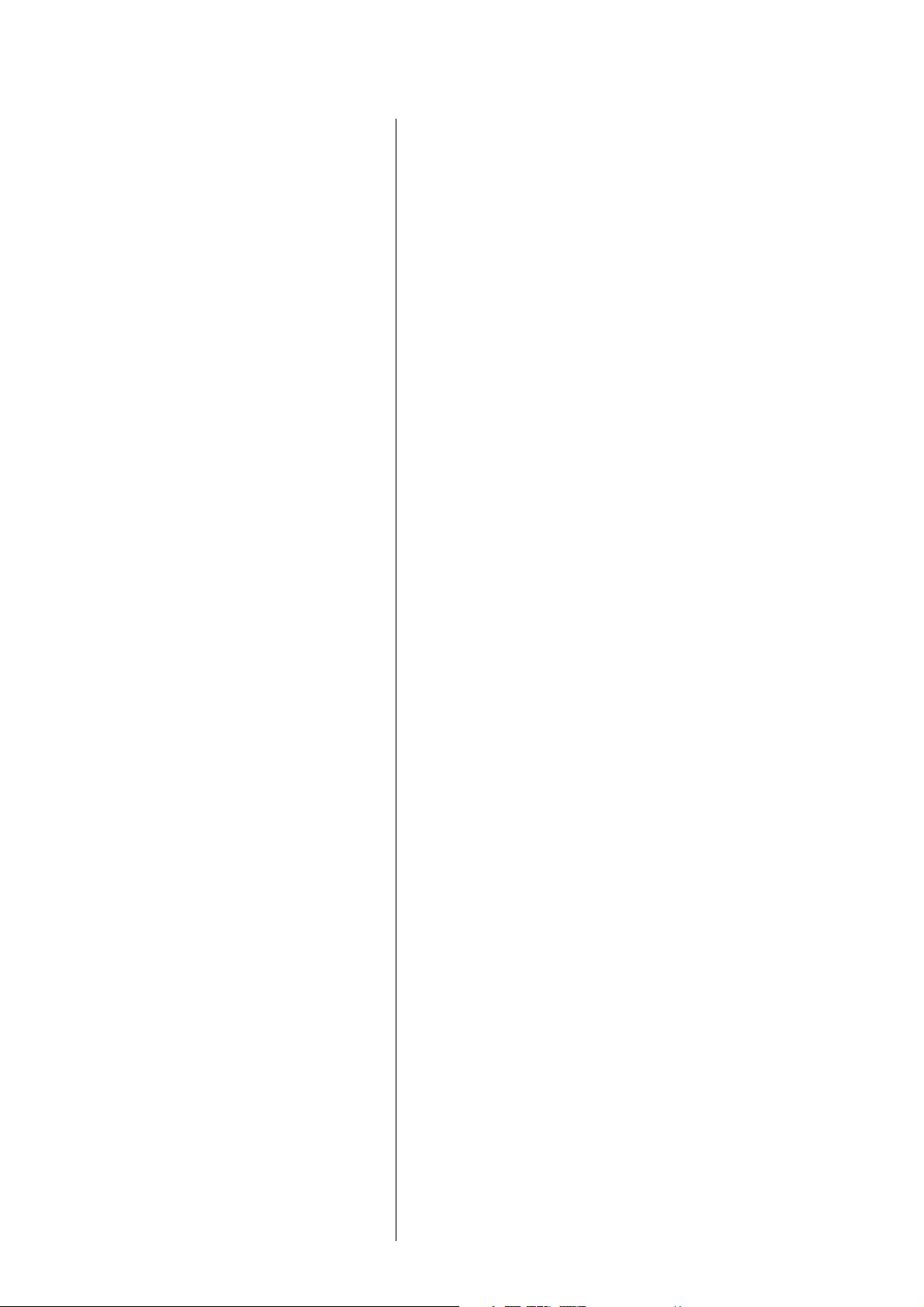

Fit the chain

Fit the bar and chain.

Fit the chain

Place the machine upright.

Place the chain in the bar and fit it

on the rim sprocket.

New chain

When a new chain has been fitted,

the bar tensioning lug must be

adjusted to its rearmost position.

New chain

Adjust the bar tensioning lug

to its rearmost position.

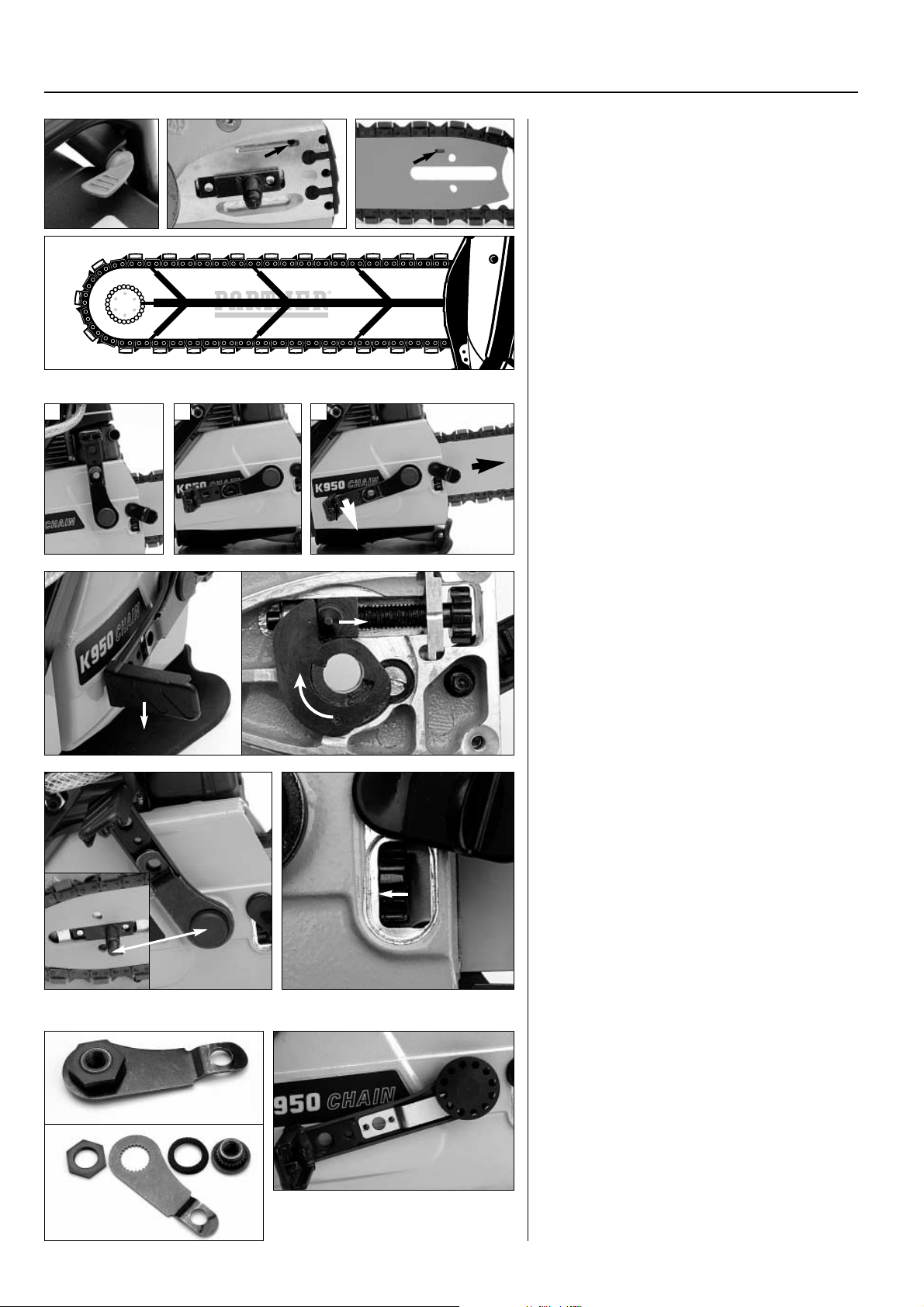

Fit the cover

Old version:

Position the cover. Fit the flange,

tighten the screws and lift into the

lever.

New version:

Press down the lock spring and fit

the castellated nut, tighten slightly.

Tension the chain as described in

chapter 5.

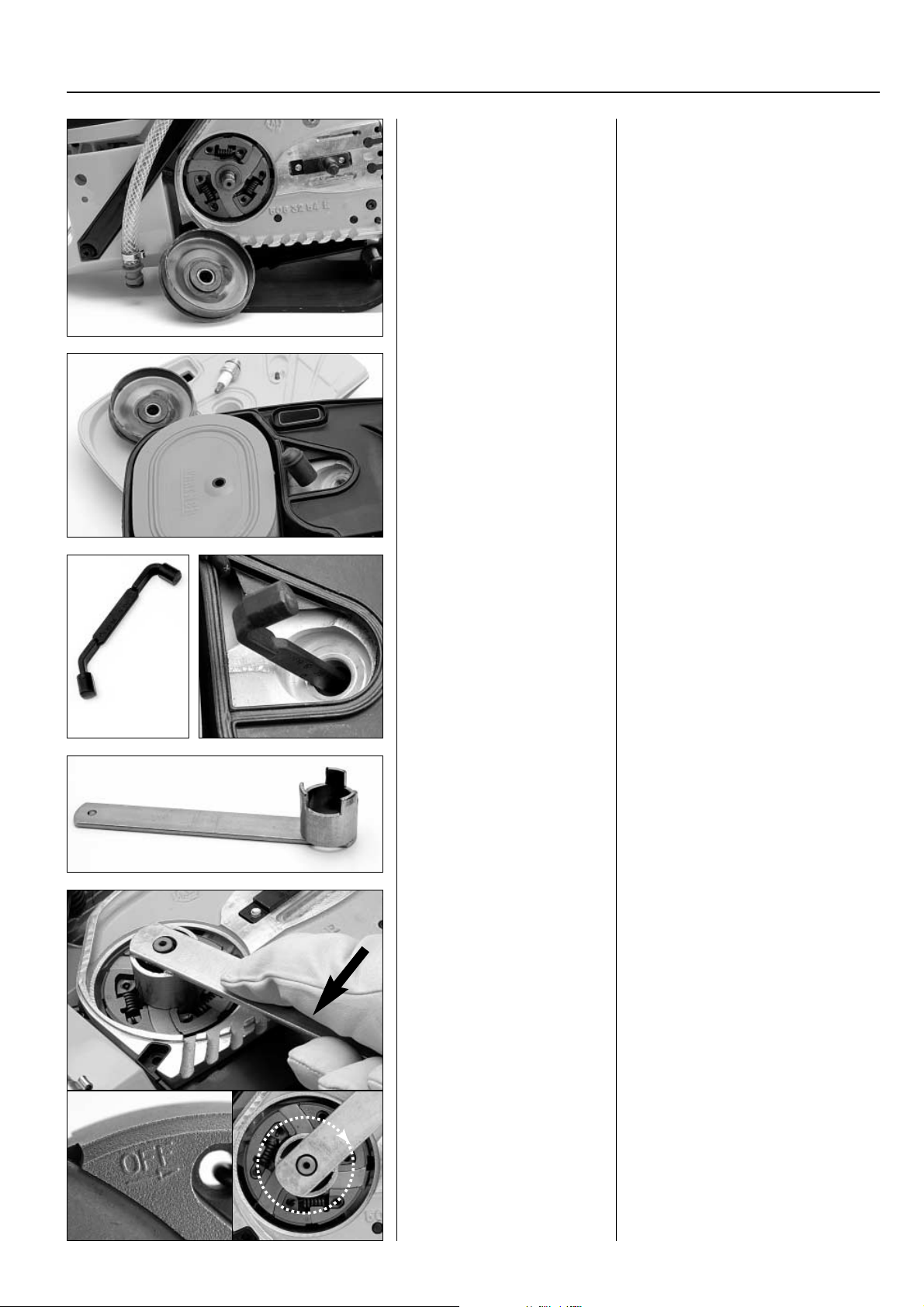

Adjust the lock-nut

When upright, the lever should lock

the bar. If the tensioning force is in-

correct, the flange nut is tightened as

follows:

Old version

1. Lift up the flange from the lever

and tighten it firmly until the bar is

securely locked.

2. Mark the nut in line with the

cover’s contour.

3. Remove the flange and undo the

nut and rubber seal.

4. Rotate the bar nut so that the

mark lines up with the arm. Fit the

seal and nut, tighten.

Adjust the lock-nut

When upright, the lever

should lock the bar. If it does

not, adjust as follows:

Old version

1. Tighten the flange until

the bar is securely locked.

2. Mark the nut in line with

the cover’s contour.

3. Remove the flange and

undo the nut at the back.

4. Rotate the bar nut so that

the mark lines up with the

arm. Fit the seal and nut,

tighten.

Fit the cover

Old version:

Position the cover. Fit the

flange and lift into the lever.

Tension the chain.

New version:

Press down the lock spring and

fit the castellated nut, tight-

en slightly. Tension the chain

as described in chapter 5.

New version

Adjust the lever’s locking position

every time the cover is fitted.Press

down the lock spring (A) and tighten

the castellated nut (B). Tighten light-

ly by hand.

Check that the castellated nut is in

the right position in the lock spring

by moving the lever upward, in line

with the cover’s contour where it

should lock the bar.

If it does not, adjust the castellated

nut. Move the lever to the horizontal

position and choose another hole in

the castellated nut.

New version

Press down the lock spring

(A) and lightly hand-tighten

the castellated nut (B).

Check that the castellated

nut is in the right position in

the lock spring by moving

the lever upward, where it

should lock the bar.

1. 2.

3. 4.

Old version New version

A

B