Centripetal Force Accessory Model No. ME-8089

4®

Introduction

PASCO’s Computer-Based Centripetal Force Accessory

(ME-8089) allows students to investigate the relationships

between centripetal force, radius, mass, and velocity for

an object undergoing uniform circular motion. Traditional

experiments in this area involve the swinging of masses

above the head. The traditional approach is difficult to

execute and data is rarely sufficient for an understanding

of the relationships. With a computer interface, Force

Sensor, and photogate, the Computer-Based Centripetal

Force Accessory removes these difficulties by allowing

the student to directly measure and observe the force and

velocity of the mass as it rotates.

Masses are included with the apparatus to facilitate a

range of mass trials. The sliding and stationary mass hold-

ers provided with the accessory attach to a PASCO Rotat-

ing Platform (ME-8951). Spinning the Rotating Platform

and allowing it to slow down (without assistance) varies

the velocity. The platform can be manually spun by hand

or automatically with a Motor Drive (ME-8955) and DC power supply. Sliding the captured

masses along the grooves in the rotating platform changes the radius. For radius measurements, a

convenient measuring scale is included on the top edge of the platform.

Equipment Setup

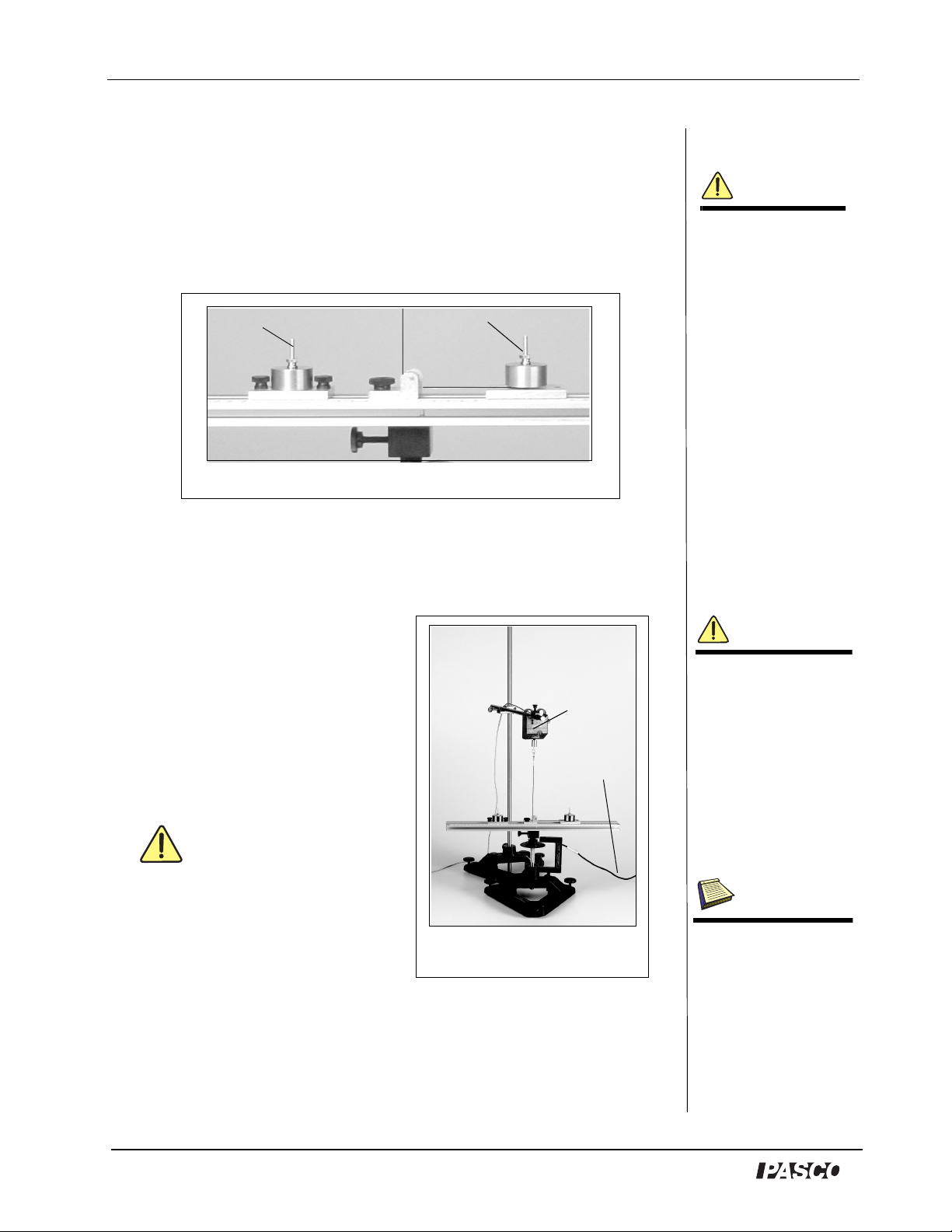

1. Insert the photogate post into the base

stand and into the photogate head.

2. Use a thumbscrew to mount a Photogate

Head (ME-9498A) to the bottom of the

“A” base (See Figure 2). Let the Photogate

Head rest over the first ring on the 3-step

pulley of the Rotating Platform. (Note:

Ensure that the positioning of the

photogate does not restrict movement of

the shaft).

3. Connect the photogate to a computer

interface (ScienceWorkshop or

PASPO RT).

Figure 1: Setup with Force

Sensor on Stand

Figure 2: Photogate on Base

of Centripetal Apparatus

photogate

pulley

steel rod

cable

to interface