OPERATOR’S SECTION

L-B B5L0082/PAT 031-300-190-015 REVISION D 04/15/99

1

OPERATOR’S SECTION

1. GENERAL INFORMATION

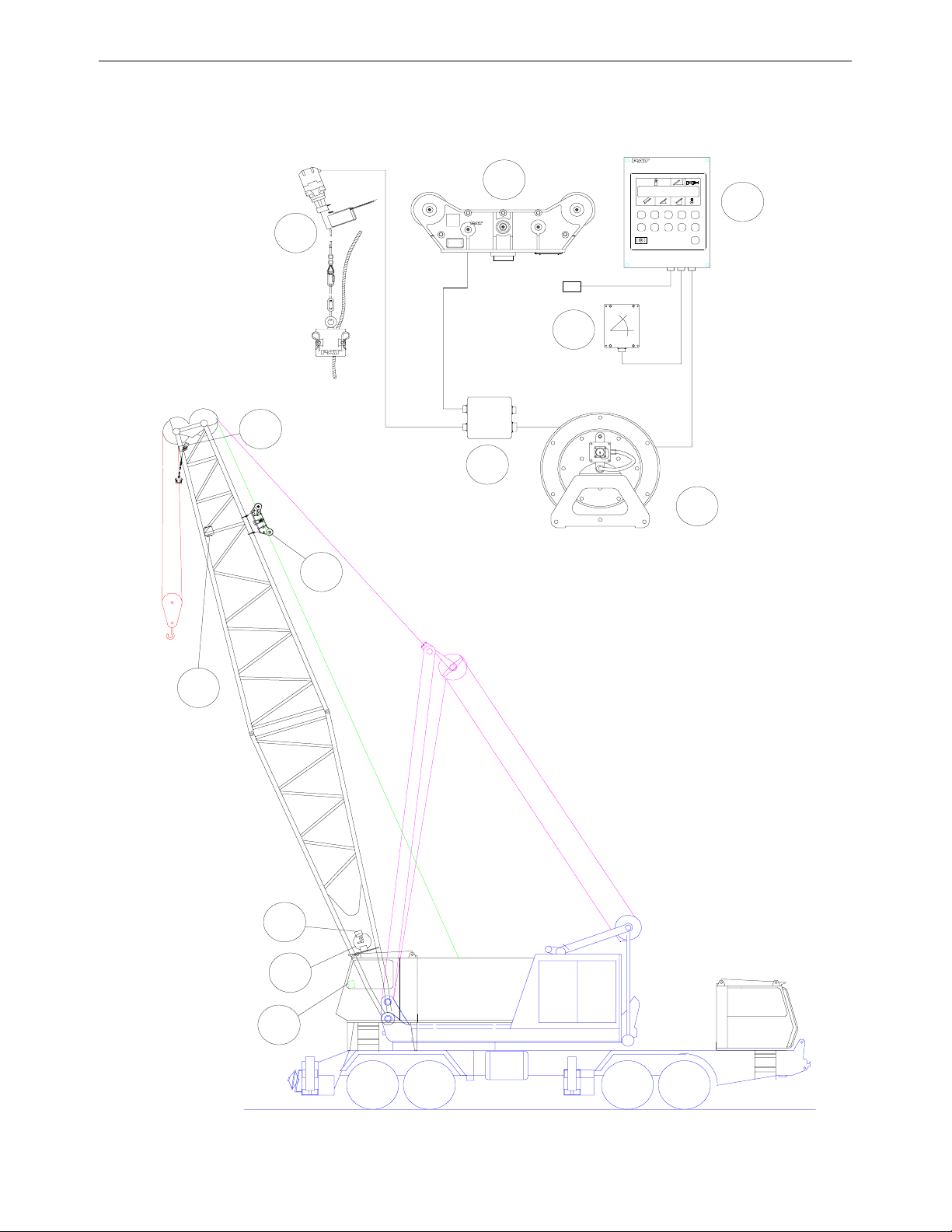

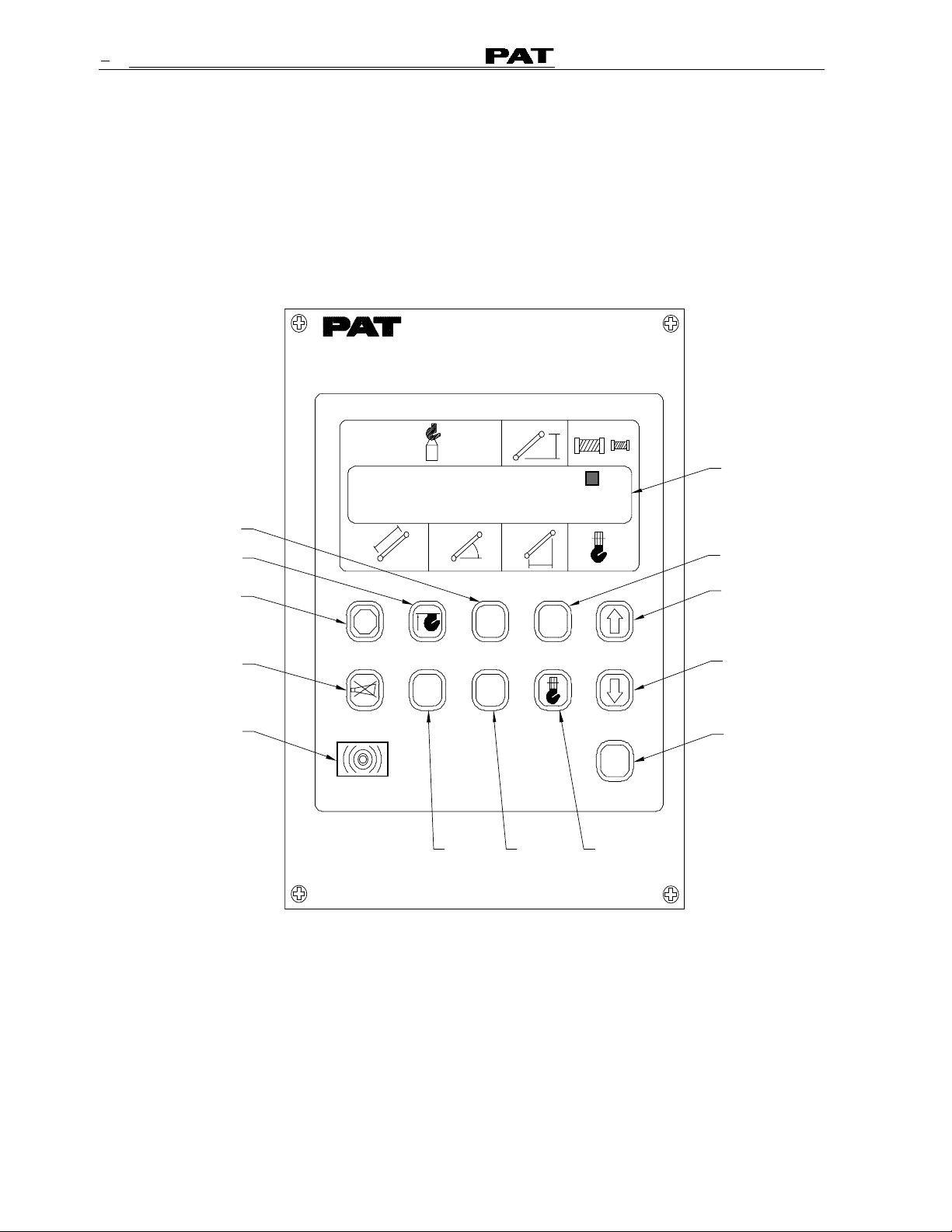

The PAT Length-Angle-Radius-Load Indicator System EI 65 has been designed to provide the

crane operator with the essential information required to enable the machine to be used

within its design parameters. The EI 65 System indicates the length and angle of the boom,

tip height, working radius and the total calculated weight being lifted by the crane.

Using various sensing devices, the EI 65 System warns the crane operator of certain

approaching hazardous conditions which could occur during the operation of his crane.

The purpose of this operator’s manual is to provide information to help him operate, maintain

and troubleshoot the PAT System.

The manual contains the system description, operating, and calibration information.

2. WARNINGS

• The EI 65 is an operational aid that warns a crane operator of certain approaching

hazardous conditions that could cause damage to equipment and personnel.

• The device is not, and shall not be, a substitute for good operator judgment, experience

and use of accepted safe crane operating procedures.

• The responsibility for the safe operation of the crane shall remain with the crane operator

who shall ensure that all warnings and instructions supplied are fully understood and

observed.

• Prior to operating the crane, the operator must carefully and thoroughly read and

understand the information in this manual to ensure that he knows the operation and

limitations of the indicator and crane.

• Proper functioning is dependent upon proper daily inspection and observations of the

operating instructions set forth in this manual.

Always refer to operational instructions and load charts provided by the

crane manufacturer for specific crane operation and load limits.