6

TSM DS 50-003/REV.C/031-300-190-003/04-20-07

DS50 TROUBLE SHOOTING MANUAL LEVEL 3

1. INTRODUCTION TO TROUBLESHOOTING THE PAT DS 50

1.1. SYSTEM OUTLINE

The PAT Overload Warning System Model DS 50 is designed to disable the

boom down and up, hoist up and tele out crane functions when the crane

attempts to lift over its limits. These limits are specified in the load capacity

chart provided by the crane manufacturer.

When the DS 50 system detects an overload condition the following crane

functions are disabled immediately.

a. telescope out

b. boom up and boom down

c. hoist up

To remove the overload condition the operator must achieve a safe working

condition. This can be achieved by lowering the load and repositioning the

crane or decreasing the radius by telescoping in. Observe that the radius can

not be decreased by lifting the boom. The boom up function is disabled while

attempting to overload the crane.

The system design allows you to operate the crane in an emergency situation

or system failure without the DS 50 system in operation. In this situation leave

the crane electric switch in the off position and press the override button while

you operate the crane manually. The DS 50 Overload Warning System is not

operative and can not warn the operator with the electric power switch in off

position.

Warning

Bypassing the DS 50 Overload Warning system

may results in property damage, injury or death.

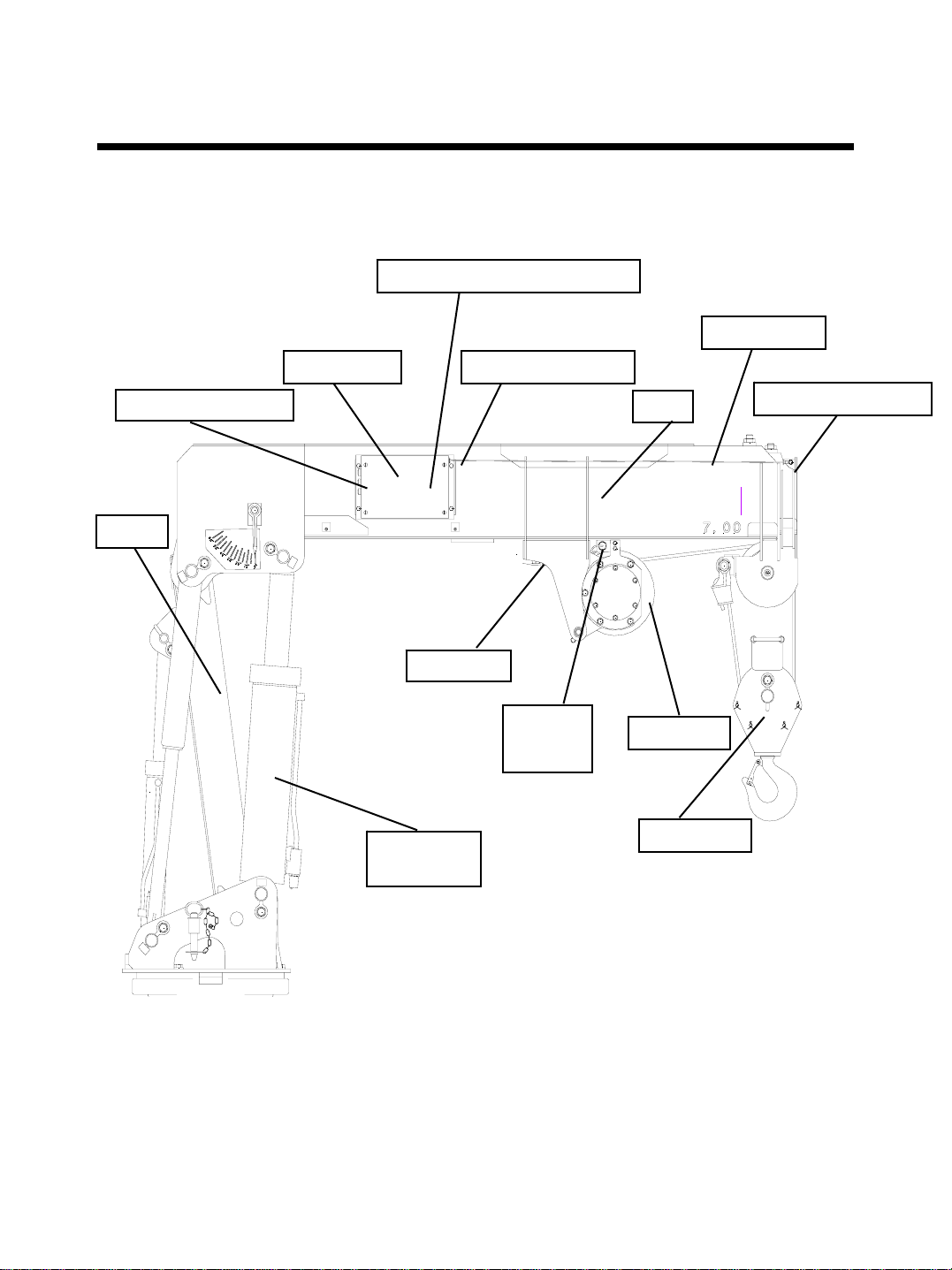

The DS 50 system contains a central unit with integrated length and angle

sensor. The load cell is supporting the hoist drum and used to measure the

load on hook.