Patol Limited

1 INTRODUCTION

1.1 General

The Patol 5000 Series of equipment is specifically designed for the protection of

establishments and systems where a movement of materials with a potential fire hazard is

a routine occurrence.

The 5000 Series system employs enhanced Infra-red monitoring technology that enables

the detection of fire initiating materials, whilst they are being transported, and before they

have reached a flame condition.

The system has many applications within industries such as Power Generation, Coal

Mining, Process Plant, Road Transportation and Rail Networks and has been specifically

designed to both meet the rigors of these environments and to provide the reliability

required.

The equipment monitors for fire and fire potential of materials in transit. The system can

detect anomalies where combustion has not yet been reached, but where there is sufficient

energy for a fire initiation upon destination arrival.

A typical example is in the coal feed systems on power stations where coal on the ‘out field

stack’ may very well smoulder with little adverse effect for long periods of time. However, if

imported to the power station it may have devastating effects on conveyor systems, holding

hoppers, blending plants etc.

♦ Detection of hazards at temperatures below flame point including both embers and

buried hot spots.

♦ Air purged system for Dusty environments with air pressure monitoring.

♦ Eight high integrity detectors for maximum reliability

♦ Multi-facet lensing provides wide uniform coverage superior to some ember/spark

detectors.

♦ Coincidence- Double Knock - option for unit detectors as standard.

♦ Timed auto reset / coincidence analyser circuit.

♦ Tuned response - solar blind.

♦ Special configurations and application specific calibration options.

♦ Specifically designed for high EMC compliance

1.2 Principles

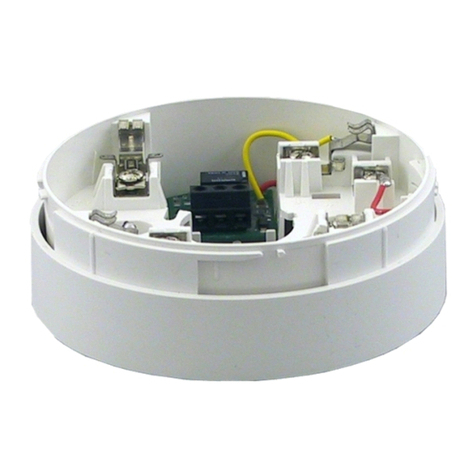

The principle of operation is that

temperature dependant black body

emissions occur for all materials.

These emissions range through the

infra red spectrum to visible light.

Both the wavelength and level of

peak energy emission are related to

temperature.

The Series 5000 detectors are

designed to detect the changes in

these emissions that occur when a

hot body enters the field of view of

the detector.

By the use of both optical filtering and electronic analysis of the various parameters the

system is blind to visible light from the sun or local luminaires, whilst being able to detect

relatively low temperature material moving through the field of view.

123456789

200 C

320 C

SOLAR

o

o

10

Typical Black Body Energy Emissions

5000 RESPONSE FILTER

WAVELENGTH (Micrometres) Fig. 1

Page 3 of 15Series 5000 - Manual 5010 / 5020 D1125 - Issue 2 - 1 December 2009