8

Proper Procedure for Operating a Model 330A

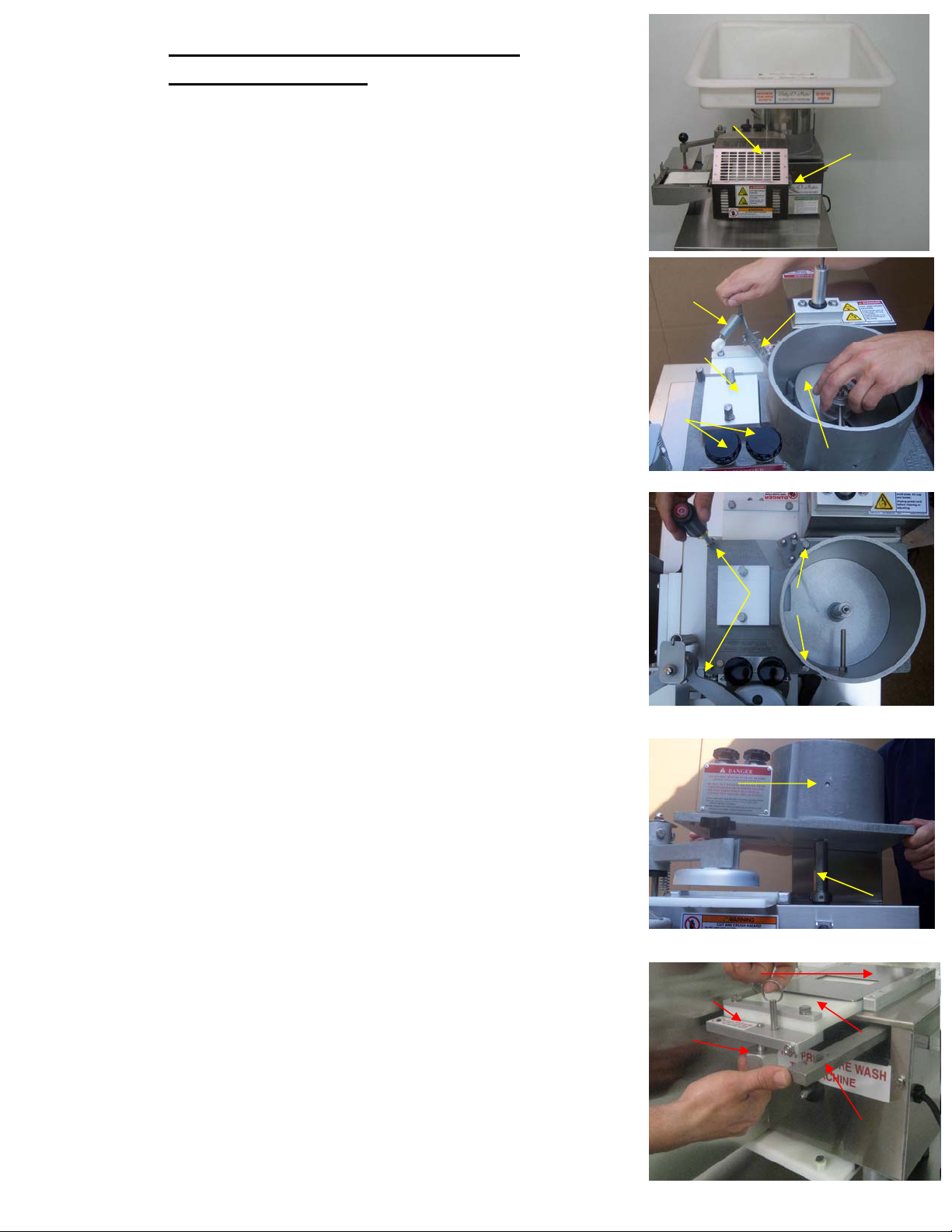

When the Model 330A is fully assembled with all guards secured in their proper

place, put product to be portion molded in the Feed Tray. Push the product through the

holes in the Feed Tray Guard into the Hopper opening. DO NOT PUT HANDS OR

FINGERS, OR FOREIGN OBJESTS, SUCH AS STOMPERS OR PLUNGERS

INTO THE HOPPER. THERE ARE NO STOMPERS OR PLUNGERS NEEDED

WHEN USING THIS UNIT, THEREFORE NONE ARE SUPPLIED. After you

allow product to drop into Hopper turn the machine on by moving the On/Off switch

down towards the on position. The machine may need to cycle a few times to prime the

machine with product. As patties are being formed continue to push product through the

holes and under the Feed Tray Guard. Patty paper may be added to the machine as

needed. The machine can hold up to 1 inch of paper at a time, but no more.

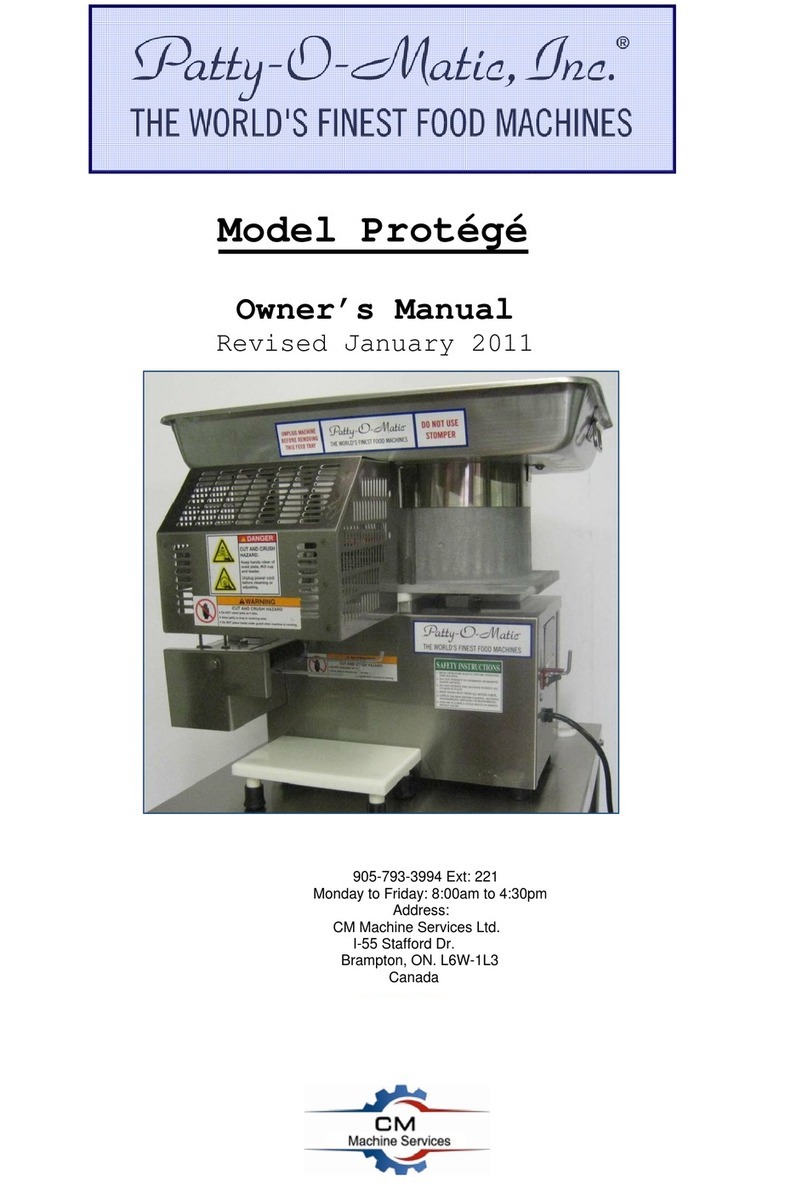

As the Mold Plate moves back and forth to form patties, a thin coating of product

may accumulate over its surface. This coating may also accumulate on the edges of the

Knock Out Cup or on the front of the Hopper and Spacer Plate. This accumulation does

occur on all molding machines. It is nothing to be concerned with. There are certain

machine settings that may lessen this accumulation.

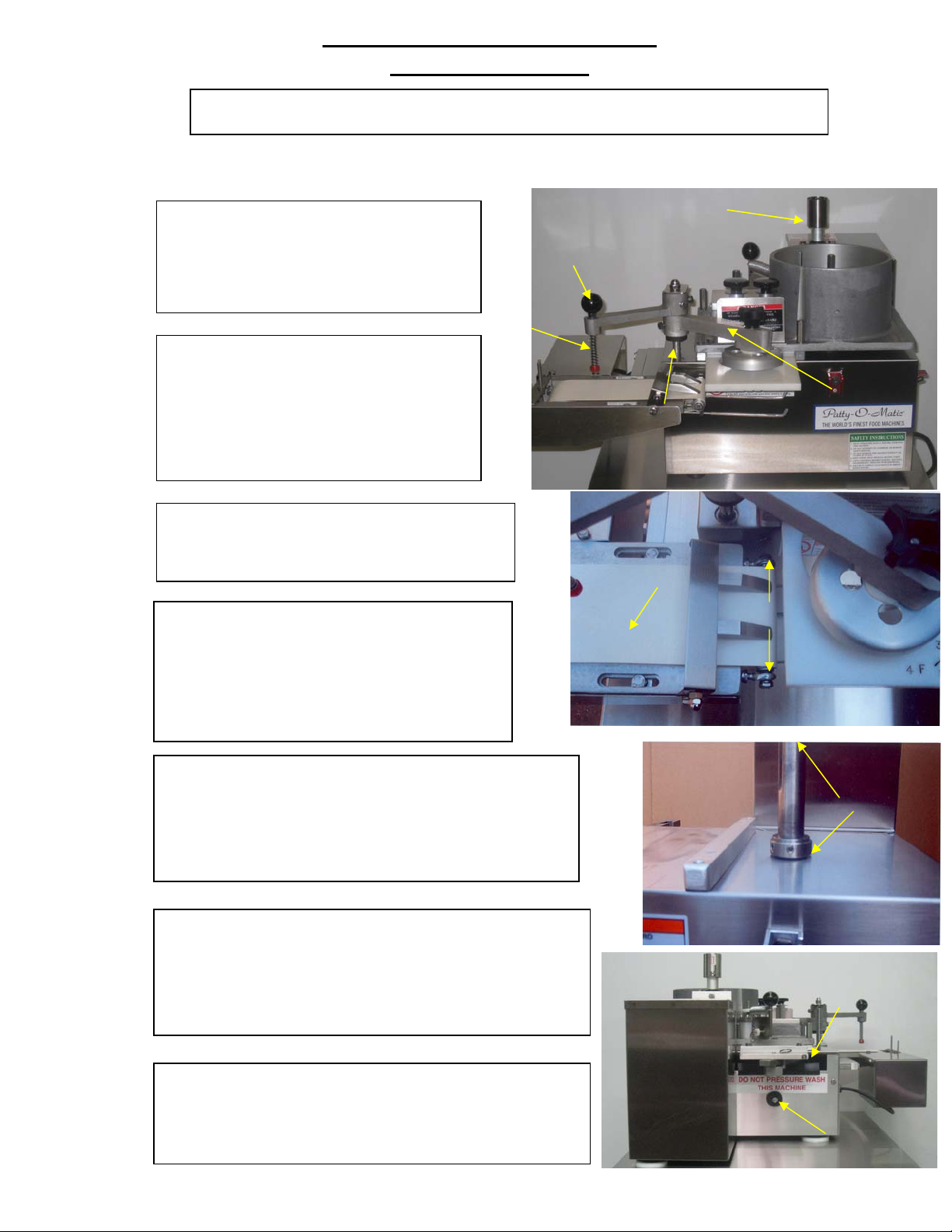

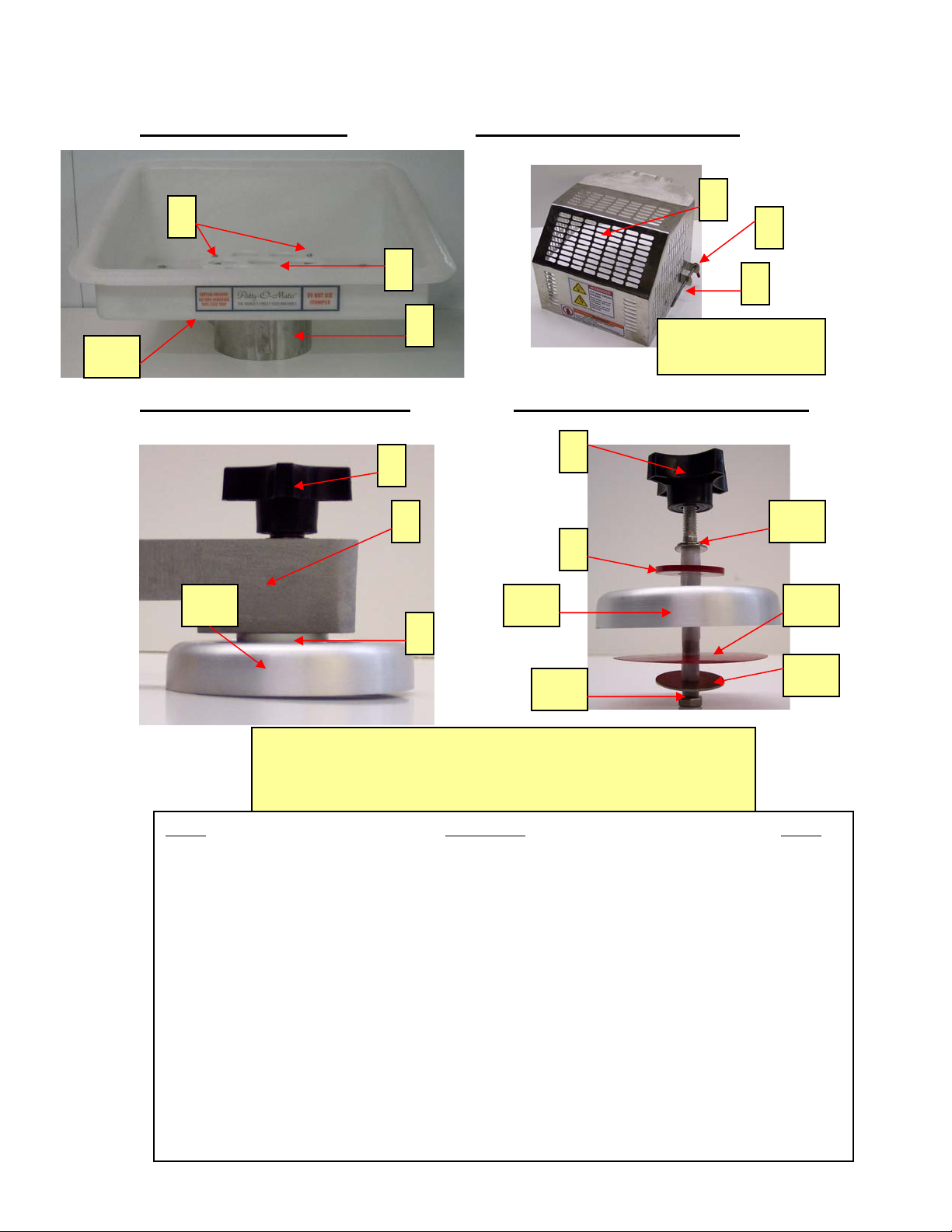

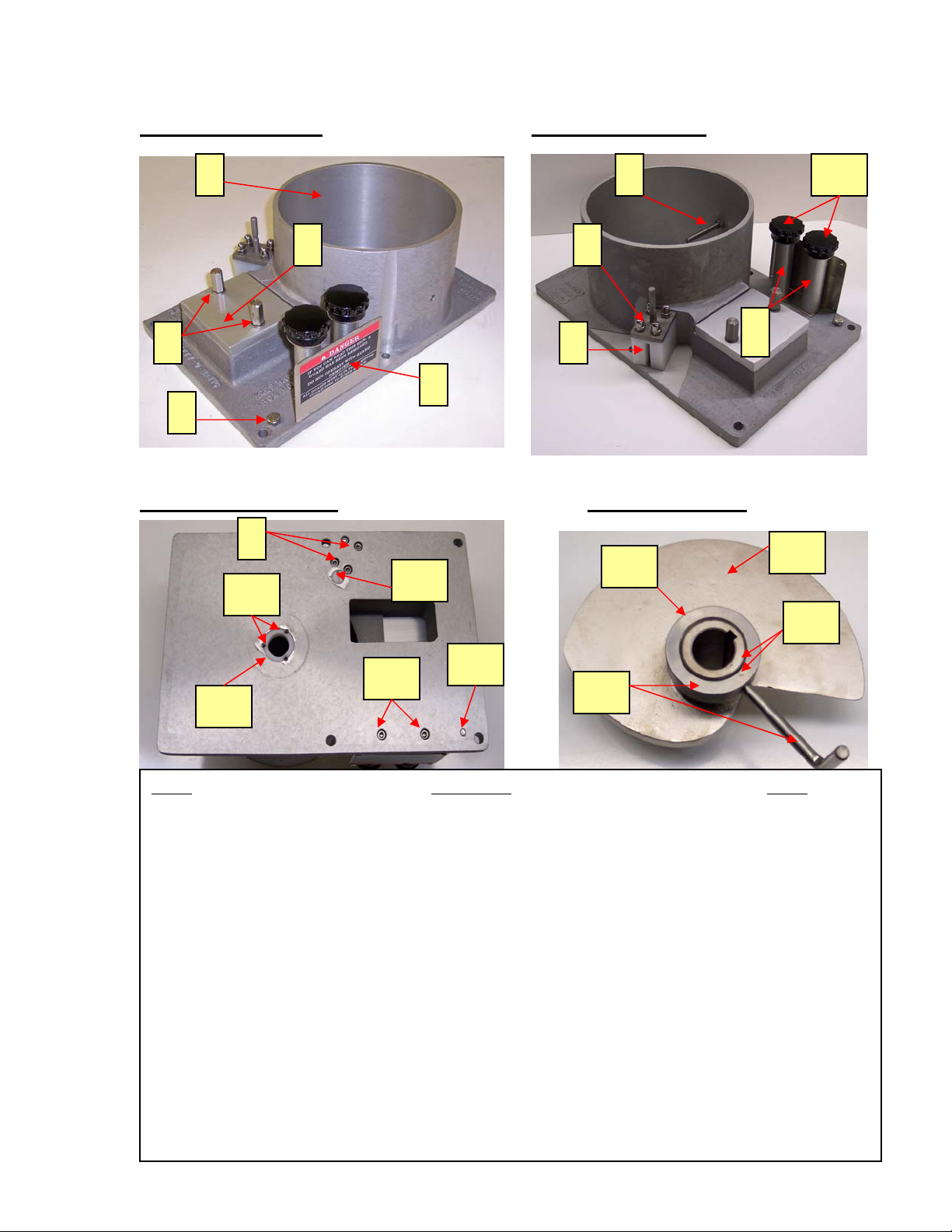

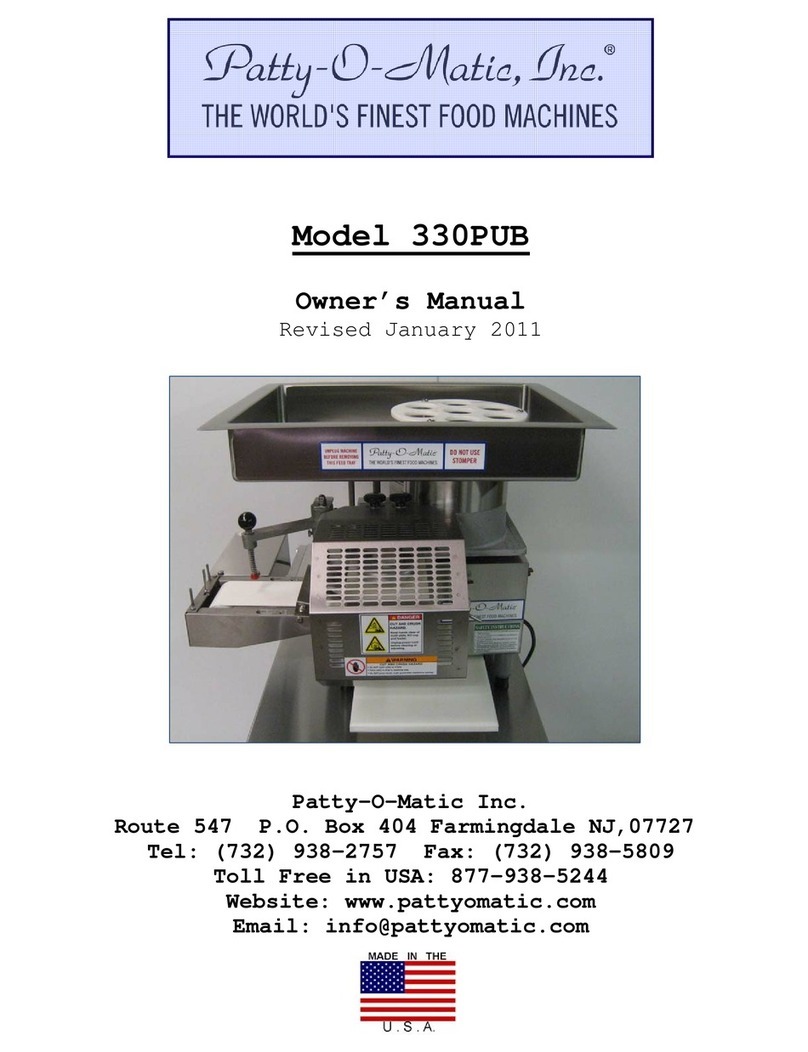

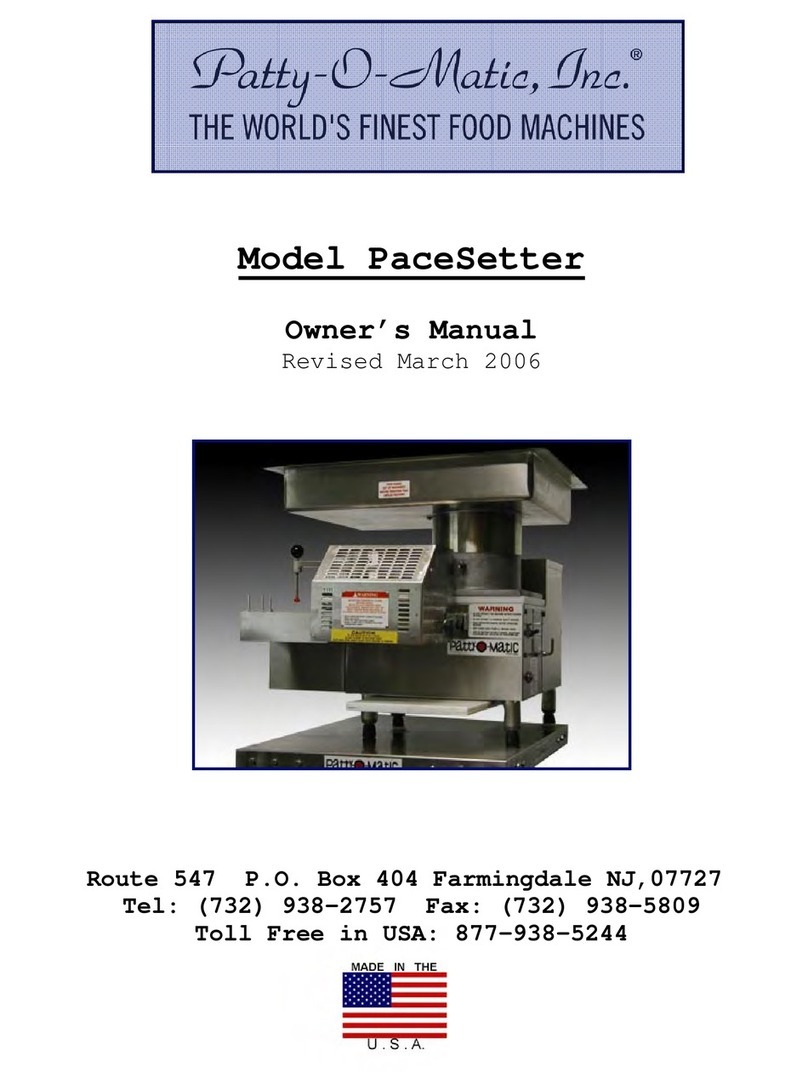

Setting the Ring Pin Pressure Plate for your Patty Size

The Purpose of the Pressure Plate is to entrap the amount of product necessary to form

your patty. This part is also used in controlling the firmness of your patty. With the Pressure

Plate set correctly you will in turn have:

- less leakage, oozing, and coating of parts

- less kneading of your product

- and less strain on your machine.

-----------------------------------------------------------

If your patty weight is 8 ounces, keep the ring pin in the storage hole as described in the

picture. This will allow the Pressure Plate to move all the way into the Hopper and stop on the

welded stop which is the maximum volume setting.

If your patty is 4 ounces remove the ring pin from the storage hole and place it in the 4

ounce hole.

If you patty weight is to be 6 ounces, place the ring pin in the 6 ounce hole.

If you would like to have a tightly packed patty, move the ring pin to a higher than

recommended setting for that particular weight.

THESE ARE ONLY RECOMMENDED SETTINGS. A VARIETY OF CIRCUMSTANCES

MAY CALL FOR YOU TO INSERT THE RING PIN IN A DIFFERENT LOCATION.

12

3

4

5

6

7

8

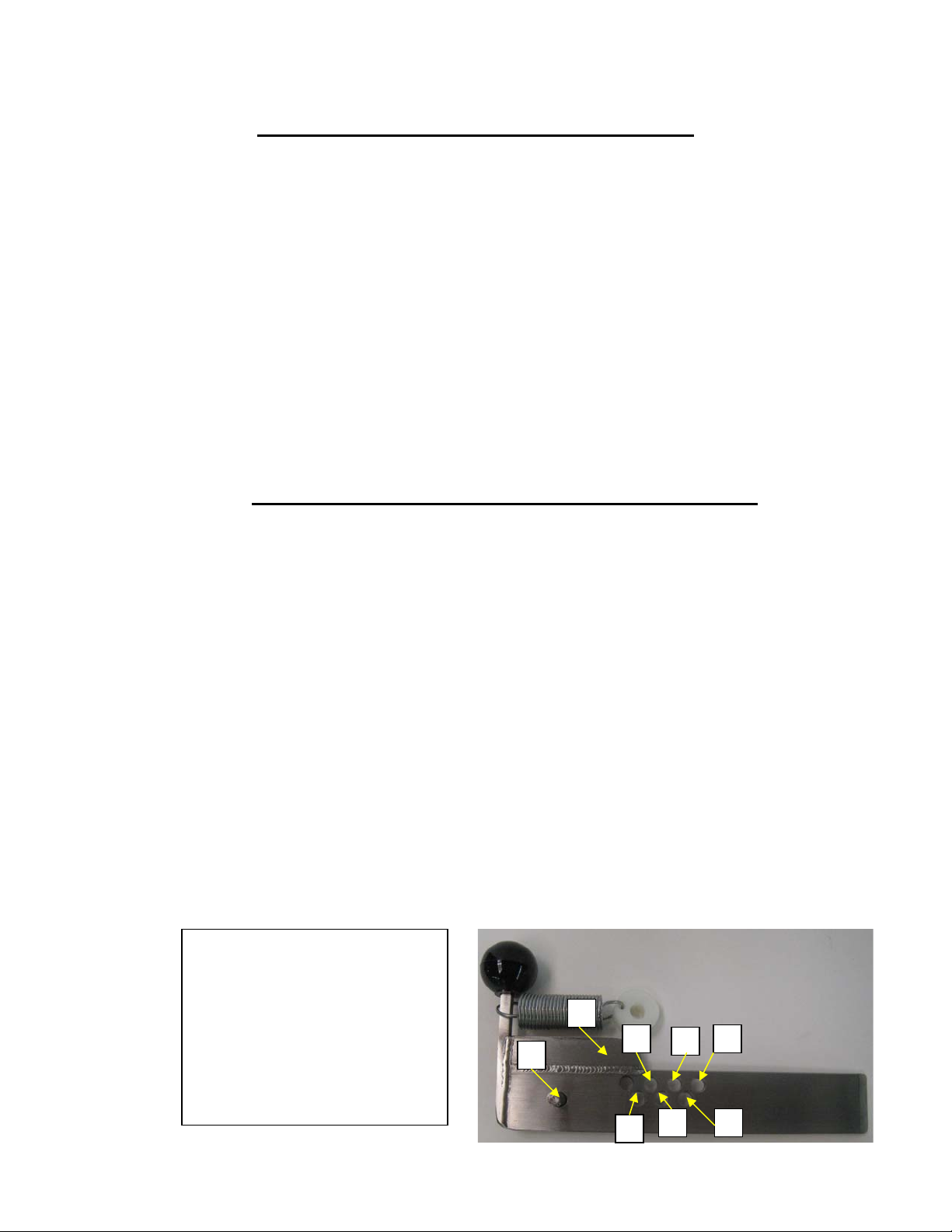

1 - Ring Pin in storage hole

2 - 2 ounce hole

3 - 3 ounce hole

4 - 4 ounce hole

5 - 5ounce hole

6 - 6 ounce hole

7 - 7 ounce hole

8 - 8 ounce welded stop