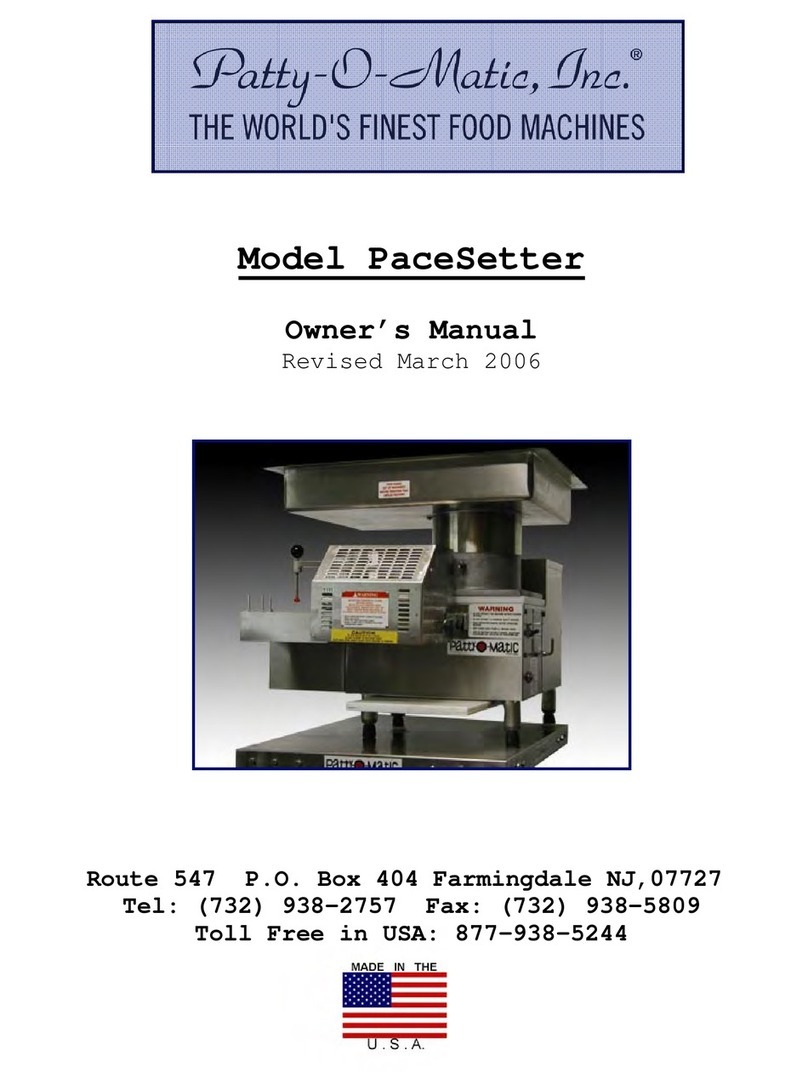

Patty-O-Matic PS21 User manual

Model PS21

Owner’s Manual

Revised October 2019

Patty-O-Matic Inc.

Route 547 P.O. Box 404 Farmingdale NJ,07727

(732)938-2757 Toll Free in USA: 877-938-5244

www.pattyomatic.com

E469483

NSF/ANSI 8

E475191

2

Table of Contents

• Introduction to Your Machine Page 3

• Installing Mold Plate Guard Page 3

• Installing Feed Tray Page 3

• Accessories Included with the Model PS21 Page 4

• Parts to Become Familiar with Page 5

• Label Location and Description Pages 6&7

• Operating Procedure Page 8

• Setting Ring Pin Pressure Plate Page 8

• Changing Mold Plate and Spacer Plate Page 9

• Proper Disassembly for Cleaning and Sanitizing Page 10&11

• Installing Patty Paper Page 12

• Points of Lubrication Page 12

Parts Representation

• Feed Tray Assembly Page 13

• Mold Plate Guard Assembly Page 13

• Knock Out Cup Assembly Page 13

• Hopper Assembly Page 14

• Feeder Assembly Page 14

• Assembled Machine Views Page 15

• Paper Interleaver Assembly Page 16

• Ring Pin Pressure Plate Page 17

• Mold Plate Assembly Page 17

• Assembled Hopper and Feeder Page 17

• Electrical Switches Page 18

• Tower Assembly Page 19

• Main Shaft Assembly Page 20

• Crank Housing Assembly Page 21

• Motor To Main Shaft Page 22

• Knock Out Cam Assembly Page 23

• Knock Out Shaft and Lever Assembly Page 23

• Main Motor Side View Page 24

• Mold Plate Guide Rails Page 24

• Main Shaft Outside Machine View Page 24

• Wiring Diagram Page 25

• Warranty Information Page 26

• Important Information Guide Page 27

• Notes Page 28

3

Installing the Mold Plate Guard

Loosen Guard Bolts on the Hopper

and the rear post. Place Mold Plate

Guard under the washers located

under the bolt heads. Tighten bolts

using the provided Speed Driver.

To activate the interlock, slide push

rod into the plunger, inside the

keylatch, and turn rod to the right.

This will lock the push rod in place

and activate the interlock.

Installing the Feed Tray

Place stainless steel tube of Feed

Tray over the Hopper. Make sure

the Plunger on the bottom of Feed

Tray depresses the Tower Stem

inside the Tower Sleeve.

Installing Machine onto Riser

Platform

Place machine on the riser platform

making sure the 4 legs of the

machine go into the 4 leg wells on

the Riser Platform. The Picture

shown shows the front view of the

Riser Platform.

Leg Wells

Thank you and congratulations on the purchase of your new Model PS21 Patty Molding Machine from

Patty-O-Matic, Inc! The Model PS21 will form, interleave paper between, and stack patties. This machine is

designed for easy operation and cleaning. Please become familiar with this manual and your machine will

give you many years of service.

The Model PS21 is shipped to you in at least three cartons which contain the patty machine, feed tray,

mold plate guard, spare parts box, receiving table, riser platform, and the manual. If you purchased your

machine with any other accessories, such as a mobile table or patty paper, these items may be in a separate

carton.

Your machine is equipped with two interlocks. One is located on the front of the machine and one is

located on the top of the machine. The Mold Plate Guard must be installed on the machine to engage the

interlock on the front of the machine and the Feed Tray including the guard must be installed on top of the

Hopper to engage the interlock on top of the machine.

Guard Bolts

Interlock Tower

Push Rod &

Round Keylatch

Plunger located

on back of Tray

If you have any questions or concerns after reading these

instructions, please do not hesitate to contact the factory at:

Feed Tray

Feed Tray

Guard

4

Accessories Equipped with the Model PS21

1

2

Item# Description Part #

1 Spare Parts Box 655

Holds Spare Parts, Patty Paper Sample, Machine Lubricant, Speed Driver, and

Locator Rings c/w instructions

2 Receiving Table 609-6

3 Speed Driver 544

4 8 Ounce Bottle of Machine Lubricant and Cleaner 600

5 Gallon of Machine Lubricant(Separate Order Only) 600A

6 Machine Locator Rings 610-2

6

3

4

5

Please become familiar with some of the parts

of your machine prior to operating machine

Mold Plate Assembly Side View

T-Knob

Mold Plate Assembly Underside View

T-Knob Hole

Feed Tray Guard

Feed Tray Guard and Mold Plate Guard are installed for your

safety. Do not tamper with them in any way!

Mold Plate Guard

Knock Out Cup

Assembly

Refer to Page 12

Please become familiar with some of the parts

of your machine prior to operation

Back Drive

Ring Pin

Hopper

Retaining Rod

Feeder

Retractable

Meat Stop

Pressure

Plate

Mixer

Collar

Chamber

Lid

Feeder Washer

Feeder Top

View

Feeder Side

View

Double Seal

Spacer Plate

Ring Pin Pressure Plate

6

Proper Label Location for a Model PS21

9

2

3

1

5

6

7

2

10

5

11

9

12

4

8

7

Item # Description Part#

1. Danger Label 3 514-09a

2. Warning Orange 514-02

3. Patty-O-Matic 514-08

4. Safety instructions 514-06

5. Danger Label 2 514-00

6. Serial Tag For UL Machines 514-15UL

7. Store Tool 514-14

8. Warning Manual 514-01

9. Danger on/off 514-05

10. Do Not Pressure Wash 514-04

11. Unplug Machine 514-07

12. Made in USA 514-19

8

Setting the Ring Pin Pressure Plate for your Patty Size

The Purpose of the Pressure Plate is to entrap the amount of product necessary to form your

patty. This part is also used in controlling the firmness of your patty. With the Pressure Plate set

correctly you will in turn have:

- less leakage, oozing, and coating of parts

- less over working of your product

- and less strain on your machine.

-----------------------------------------------------------

If your patty weight is 8 ounces, keep the ring pin in the storage hole as described in the

picture. This will allow the Pressure Plate to move all the way into the Hopper and stop on the

welded stop, which traps the most product and is the maximum volume setting.

If your mold cavity is for 4 ounces, remove the ring pin from the storage hole and place it in

the 4 ounce hole.

If your mold cavity is for 6 ounces, place the ring pin in the 6 ounce hole.

If you would like to have a tightly packed patty, move the ring pin to a higher than

recommended setting for that particular weight.

THESE ARE ONLY RECOMMENDED SETTINGS. A VARIETY OF CIRCUMSTANCES MAY

CALL FOR YOU TO INSERT THE RING PIN IN A DIFFERENT LOCATION.

2

1

3

5

6

1 - Ring Pin in storage hole

2 - 2 ounce hole

3 - 3 ounce hole

4 - 4 ounce hole

5 - 5ounce hole

6 - 6 ounce hole

7 - 7 ounce hole

1

8

4

7

Proper Procedure for Operating a PS21

When the Model PS21 is fully assembled with all guards secured in their proper place, put product to be

molded in the Feed Tray. Push the product through the holes in the Feed Tray Guard, or under the Feed Tray

guard and into the Hopper. DO NOT PUT HANDS OR FINGERS, OR FOREIGN OBJECTS, SUCH AS

STOMPERS OR PLUNGERS INTO THE HOPPER. THERE ARE NO STOMPERS OR PLUNGERS

NECESSARY WHEN USING THIS UNIT, THEREFORE NONE ARE SUPPLIED. After you allow

product to drop into the Hopper turn the machine on by moving the On/Off switch down towards the on position.

The machine may need to cycle a few times to prime the machine with product. As patties are being formed

continue to push product through the holes and under the Feed Tray Guard. Patty paper may be added to the

machine as needed. The machine can hold up to 1 inch of paper at a time, but no more.

As the Mold Plate moves back and forth to form patties, a thin coating of product may accumulate over its

surface. This coating may also accumulate on the edges of the Knock Out Cup or on the front of the Hopper and

Spacer Plate. This accumulation does occur on all molding machines. It is nothing to be concerned with. There

are certain machine settings that may lessen this accumulation.

9

Mold Plate and Connecting Arm Rear View

Hopper Front View Double Seal Spacer Plate

Back Drive

Connecting Arm

Mold Plate

Ring Pin

Retaining Rod

Guard Block

Thickness

Fraction Stamp

Retaining Rod

Location Hole

T-Knob

Double Seal

Spacer Plate

Changing Your Machine’s Mold Plate

Always disconnect the machine from its power source

before attempting to change or clean any of the machines component parts.

If the Mold plate is all the way into the machine, remove the T-Knob from the Back Drive by lifting the ring

pin and unthreading the knob. Pull the Mold Plate out from the back of the machine. If the Mold Plate is slightly

out of the machine and you prefer to remove it without removing the T-Knob, simply pull the ring pin out and

unhook the Connecting Arm from the T-Knob. Then slide the Mold Plate from the back of the machine.

When changing the Mold Plate always use the corresponding Double Seal Spacer Plate and Knock Out Cup.

The thickness fraction stamped on the Double Seal Spacer Plate should match the fraction stamped on the front

right corner of the Mold Plate. For example: if your Mold Plate is stamped “4F ½” then the Double Seal Spacer

Plate should be stamped “1/2”. The Double Seal Spacer Plate is held in place by the Retaining Rod. The Retaining

Rod is secured by a spring into the Guard Block. Lift the Retaining Rod up and to the side so it does not protrude

into the Double Seal Spacer Plate. There is no need to remove the Retaining Rod from the Guard Block. After

putting the new Mold Plate and corresponding Double Seal Spacer Plate into the machine, lift the Retaining Rod

and let it go into the hole located on the front of the Double Seal Spacer Plate. Make Sure that the Double Seal

Spacer Plate is in the locked position and the O’Rings are facing up. Failure to do so may cause the Double Seal

Spacer Plate to move with the Mold Plate, and could damage the machine. Since no Double Seal Spacer Plate is

required when using a 3/4” Mold Plate, leave the Retaining Rod in the storage position.

This Side Up

10

- Remove the four Hopper Bolts using the

provided speed driver. The two bolts on

the Chamber Lid may be removed for

additional cleaning.

- Remove Pressure Plate by detaching

Pressure Plate Spring and sliding Pressure

Plate from inside of the Hopper. Pull

Retractable Meat Stop out of the hopper

until it stops. Remove feeder by loosening

bolt using the tool provided. Twist feeder

washer away from bolt and lift feeder from

the inside

- Remove Feed Tray by lifting it off the

Hopper, and Mold Plate Guard by

loosening the Guard Bolts, and unlatching

the push rod.

- Remove the Mold Plate by pulling the ring

pin and disengaging the Connecting Arm

from the T-Knob. This will allow the Mold

Plate to be removed from between the Guide

Rails and removed from the machine. The T-

Knob may also be un-screwed from the Back

Drive as an alternate means of disassembly.

Proper Disassembly for Cleaning

your Model PS21

Always Unplug Machine from its

Electrical Source Before Cleaning

-Loosen the two Hopper Bolts using the

disassembly tool provided. The two bolts on

the chamber lid may be loosened to be able to

remove the Chamber lid for additional

cleaning if necessary.

10

Feed Tray

Mold Plate Guard

Chamber

Lid

Guard Bolt

Hopper Bolts

Hopper

Main Shaft

Mold Plate

Back Drive

T-Knob

Spacer Plate

Connecting Arm

Retractable

Meat Stop

Ring Pin

Guard Bolt

Feeder

Washer

Pressure Plate

Spring

Pressure Plate

Chamber

Lid Bolts

Main Shaft

- Remove Hopper by sliding it toward the

on/off switch and lifting it off the Main

Shaft.

- After the Hopper is removed from the

machine, remove Spacer Plate from the top

of the Mold Plate. *Note--Occasionally the

Spacer Plate sticks to the bottom of the

Hopper. 3/4” Molds do not use a spacer

plate. Retaining Rod should be left in

storage position when using a 3/4” mold.

11

!

*To Re-Assemble the Machine reverse the above procedure. Hopper bolts should only be hand

tightened with the speed driver provided.

*The Knock Out Cup Should be installed on the Machine before the Feed Tray and Mold Plate

Guard, but after all other parts are in place. The Mold Plate should be all the way forward and the

Knock Out Arm should be in the down position for the cup to align with the Mold Plate properly.

Patty-O-Matic Inc. offers the highest quality patty paper, machine lubricant, and

machine grease. Please contact the factory for information on these products.

Paper Sleeves Stops should be

adjusted for different size patty paper

- Remove the Knock Out Cup by loosening

the Knock Out Knob while holding the other

end of the bolt with the Speed Driver

provided with the machine.

- All of the parts that were removed from the

machine can now be washed and sanitized

thoroughly. USDA recommends the

sanitizing solution should be 50 parts per

million but no more than 200 parts per

million. The machine itself should be

cleaned and sanitized by hand. After all

the parts are cleaned, sanitized and dry

they should be coated in mineral oil as an

extra protectant.

DO NOT HOSE DOWN OR PRESSURE

WASH THIS MACHINE!

Installing Patty Paper on Interleaver

-Place a stack of paper no thicker

than 1 inch under the pressure foot.

Slide the hole in the paper over the

center pin.

*Placing more than 1 inch of paper

may cause improper paper feeding.

Center Pin

Shown without guard for better visual

Knock Out Knob

Speed Driver

Pressure Foot

Paper Sleeve Stops

Knock Out Cup

12

!

Points of Daily Lubrication For

Your Model PS21:

The Following Parts should be lubricated daily

- Pressure Foot should be lifted up

and oiled. Hold the Acorn Nut and

lift up. Place a few drops of oil on

the Pressure Foot shaft.

Always Unplug Machine and use Food Approved Oil and Grease!

- Knock Out Shaft should be oiled

when the Knock Out Arm is in the

up position. The picture shown

displays the Arm in the up position.

- Tower Stem should be oiled when the

Feed Tray is removed as shown.

- Rod End Bearings should be oiled

with a few drops of oil. There are two

Rod End Bearings to be oiled. Do not

allow oil to drip onto the Conveyor

Belt.

- Main Shaft should be oiled when the

machine is disassembled as shown in this

picture. Be sure to oil the bottom of the shaft

by the Hopper Bushing.

- The inside of the machine can be lubricated

through the Rear Inspection Opening. By

spraying lithium grease here, you can

lubricate all internal moving components.

- The Grease Fitting on the side of the machine

by the On/Off switch should be greased once

every two weeks. 3 to 4 shots of grease are

recommended.

Tower Stem

Pressure

Foot Shaft

Rod End

Bearings

Main Shaft

Acorn Nut

Rear Inspection

Hole

Grease Fitting

located on this side

Conveyor Belt

Knock Out Shaft

Knock Out Arm

13

!

Grease Fitting

Item# Description Part #

1 Quick Feed Tray Guard Assembly 543-QP

2 Feed Tray Guard Hardware 541-B

3 Stainless Steel Flange Support 554

4 Mold Plate Guard Assembly PS21-550SC

5 Push Rod Collar 553-1B

6 Push Rod 553-5

5&6 Push Rod and Collar Assembly 553

7 Knock Out Knob PS21-571-7

8 Knock Out Arm (partial view) 502B

9 Knock Out Cup Plastic Washer 571-6

10 Round Knock Out Cup(Specify Size) 571-1

11 Knock Out Cup Flat Washer and Lock Washer 571-8

12 Knock Out Air Valve (shown in red for visual affect) 571-4

13 Knock Out Cup Bolt 571-9

14 Knock Out Cup Fender Washer 571-10

15 Feed Tray Tower Plunger and Bolt(Located on the bottom

of the feed tray) 620-17

-Knock Out Cup Assembly is Part #PS21-571

-Knock Out Cup Hardware Only is Part #PS21-571-H1

Poly Coved Feed Tray

Mold Plate Guard

Knock Out Cup Assembly

Knock Out Cup Assembly

Exploded View

1

3

15

5

10

9

7

14

11

9

7

4

6

2

8

12

13

14

2-1/4”

space

Item# Description Part #

1 Hopper Casting PS21-545

2 Chamber Lid PS21-545-A

3 Hex Hold Down Bolt (also used as Hopper hold down) 556B

4 Retaining Rod PS21-551-1C

5 Guard Block PS21-551-C

6 Retractable Meat Stop PS21-555

7 Pressure Plate Block Hardware 548-CR

8 Pressure Plate Block Assembly PS21-547-YR

9 Feeder PS21-557

10 Retaining Rod Spring 551-1A

11 Hopper Threaded Plug 607

12 Guard Block Mounting Screws PS21-551-C1

13 Feeder Washer PS21-560

14 Mixer Collar Set Screw 559

15 Mixer Collar PS21-558

16 Shear Key and Screw PS21-562

17 Feeder Washer Bolt PS21-558B

Hopper Front View

Hopper Rear View

4

5

Feeder Top View

Hopper Bottom View

11

12

13

14

7

9

3

4

10

8

7

5

3

2

1

6

15

16

17

6

15

Many parts are also sold as assemblies. Please

contact the factory for further information:

Toll Free in the U.S.A. 877-938-5244

Outside the U.S.A. 732-938-2757

Machine Front View

Machine Left Side View

Machine Rear View

Machine Right Side View

Item# Description Part#

19 Feed Tray Tower Sleeve 620-16

20 Feed Tray Tower Block 620-6

21 Tool Holder 601

22 On/Off Switch 500

23 Power Cord 115-01

24 On/Off Switch Guard 501

25 Round Key Latch Assembly PS21-553-R

26 Plunger Switch(Located inside machine) 608-1B

27 Ring Pin Pressure Plate 546-3

28 Mold Plate Back Drive 564

29 Connecting Arm 455

30 T-Knob 567

31 Grease Fitting 701

32 Knock Out Spring Threaded Holder 490E

33 Ring Pin 546C

34 Weight Shaft Support Hardware 530

Item # Description Part #

1 Paper Interleaver Arm and Bolts PS21-505

2 Knock Out Arm and Bolts 502B

3 Knock Out Cup 571-1

4 Paper Weight 532

5 Knock Out Bumper PS21-504

6 Knock Out Shaft PS21-449

7 Conveyor Belt 534

8 Pressure Bolt Tip 506D

9 Pressure Bolt PS21-506

10 Pressure Foot Spring 508

11 Pressure Foot Hardware PS21-506B

12 Paper Interleaver Arm Bolt(2) PS21-505-1

13 Knock Out Shaft Acorn Nut 503

14 Knock Out Spring Tab PS21-498C

15 Knock Out Spring PS21-490

16 Knock Out Arm Bolt(2) 502-1

17 Knock Out Shaft Bushing (white bushing pressed

into Machine Frame) 462

18 Paper Interleaver Arm Bushing (white bushing)

505-1B

1

2

3

4

6

7

8

9

10

11

12

5

34

13

14

15

16

17

32

18

19

20

21

22

24

25

26

23

27

28

29

30

31

33

16

!

Paper Return

Bracket

Paper Motor

Paper Interleaver Top View

Item # Description Part #

1 Paper Interleaver Motor c/w

Extension Shaft 516

2 Weight Shaft 527

3 Weight Shaft Support 529

4 Rod End Hardware 523

5 Rod End Bearing (2 required) 522

6 Paper Interleaver Front Pulley 521

7 Paper Weight (2 required) 532

8 Interleaver Adjustment Slots N/A

9 Paper Interleaver Back Pulley 520

10 Pin Holder Bolt and Nuts

(2 required) 526

11 Paper Pin, Nuts, and Washers 525

12 Paper Pin Assembly 524-A

13 Motor Extension Shaft and Screws 517

14 Paper Sleeve Stop 248A

15 Stainless Steel Paper Pivot Rod(2) 247

16 Paper Stop 248

17 2 Return Bracket Mounting Screws249

18 Left Return Spring 246L

19 Right Return Spring 246R

Item# Description Part#

20 Spring Adjusting Collar w/ set screw 244

21 Set Screw (one in each collar) 245

22 Pivot Rod Support Bracket 243

23 Paper Motor Cover c/w Hardware PS21-537

24 Interleaver Support Hardware 499

25 Interleaver Support Bar PS21-497

26 Interleaver Support Bar Spacers PS21-498

27 Weight Shaft Hardware 528

28 Conveyor Belt 534

29 Conveyor Belt Guard PS21-536

30 Paper Interleaver Casting Frame 519

31 Weight Shaft Spacers (Not Shown) 531

32 Interleaver to Support Bar Hardware PS21-539-1

5

5

10

1

2

6

7

4

4

8

9

10

11

12

3

31

26

25

32

13

14

19

18

22

21

20

17

16

15

24

23

27

28

29

30

17

!

Hold Down Bolt

Ring Pin Pressure Plate

Mold Plate Bottom View

PS21 Feeder Washer

& Shear Key

Hopper and Feeder Assembly

Double Seal Spacer Plate

May be metal

Mold Plate Side View

Item # Description Part #

1 Pressure Plate Spring and collar 549

2 Ring Pin Adjustment Holes N/A

3 Ring Pin(shown in

the storage hole) 546C

4 Ring Pin Pressure Plate 546-3

5 Back Drive Stop Bolt 565

6 Mold Plate Back Drive 564

7 Air Grooves (colored for visual) N/A

8 Round Mold Plate Only 563-1

9 Set of Back Drive Hardware 568A

Item # Description Part #

10 Back Drive Clamp 568

11 T-Knob 567

12 Hopper Casting PS21-545

13 Hold Down Bolt 556B

14 Feeder Washer PS21-560

15 Retractable Meat Stop PS21-555

16 Shear Key and Screw PS21-562

17 Spacer Plate( Specify Size) 569DS

18 PS21 Feeder Washer bolt PS21-558B

19 Double Seal Spacer Plate O’Rings 569A

Part # PS21 -563 - Mold Plate Assembly

-Includes Round Mold Plate, Back Drive Assembly and Knock Out Cup Assembly

Other Shapes Available

4

2

1

3

8

6

5

7

9

10

16

11

13

14

14

13

15

12

17

13

18

19

18

!

Machine Switches Front View

Guard Switch Interior View

On/Off Switch Interior View

Tower Switch Interior View

Item# Description Part

1 Round Key Latch 609-A1

2 On/Off Switch Guard 501

3 On/Off Switch Boot 500B

4 Power Cord 115-01

5 Wire Grommet 487

6 Guard Switch 608-1B

7 Guard Switch Wire 608-1D

8 On/Off Switch (insulated in electrical tape) 500

9 Tower Switch 620-10B

10 Tower Switch Wire 620-10A

11 15 AMP Circuit Breaker 115-15

Part # 608-5A – Includes Guard Switch and Wire Part # 620-10 – Includes Tower Switch and Wire

8

7

1

2

3

4

5

6

1

9

10

11

3

3

11

19

!

Tower Assembly w/ Tower Block

Tower Assembly

Exploded Bottom View

Tower Assembly Top View

Item# Description Part #

1 Tower Sleeve 620-16

2 Tower Stem 620-3

3 Tower Tube 620-5

4 Tower Block 620-6

5 Tower Locator Lock Bolt 620-7

6 Tower Switch 620-10B

7 Rubber Seal 464S

8 Tower Block Hardware 620-8

9 Tower Jam Nut 620-06

10 Tower Spring 620-9

11 Tower Acorn Nut 620-15

12 Tower Bushing 620-4

13 Tower Switch Wire 620-10A

1

3

4

5

7

13

Tower Assembly

Machine View

6

2

3

6

10

1

11

9

12

2

3

1

3

8

4

20

!

Main Shaft Assembly Interior View

Main Shaft

Exploded View

2

3

5

1

2

7

9

10

3

11

12

5

1

Item# Description Part#

1 Main Shaft Bushing (pressed into Machine Frame) 470

2 Main Shaft Thrust Washer 469-1

3 Timing Sprocket 465T

4 Chain Tension Adjuster Bolt 463

5 Main Shaft Bearing (pressed into Machine Frame) 464A

6 Timing Chain and Link 471

7 Main Shaft Clamp 467

8 Main Shaft Clamp Hardware 468

9 Main Shaft Fender Washer and Hardware 240-1

10 Main Shaft Driven Sprocket(Specify Amount of Teeth) 240

11 Main Shaft Threaded Insert Set Screw 464-2

12 Main Shaft Threaded Insert c/w Set Screw and Locking Nut 464-1

13 Main Shaft Sprocket Key 241

14 Grease Line System(Not completely shown) PS21-704

15 Main Shaft C/W Insert and Set Screw 464

8

7

6

4

14

15

9

10

13

Table of contents

Other Patty-O-Matic Commercial Food Equipment manuals

Patty-O-Matic

Patty-O-Matic Pacesetter User manual

Patty-O-Matic

Patty-O-Matic 330A User manual

Patty-O-Matic

Patty-O-Matic 330A User manual

Patty-O-Matic

Patty-O-Matic 330PUB User manual

Patty-O-Matic

Patty-O-Matic Protege User manual

Patty-O-Matic

Patty-O-Matic Protege User manual

Patty-O-Matic

Patty-O-Matic PR12 User manual