Patty-O-Matic Protege User manual

Other manuals for Protege

1

Table of contents

Other Patty-O-Matic Commercial Food Equipment manuals

Patty-O-Matic

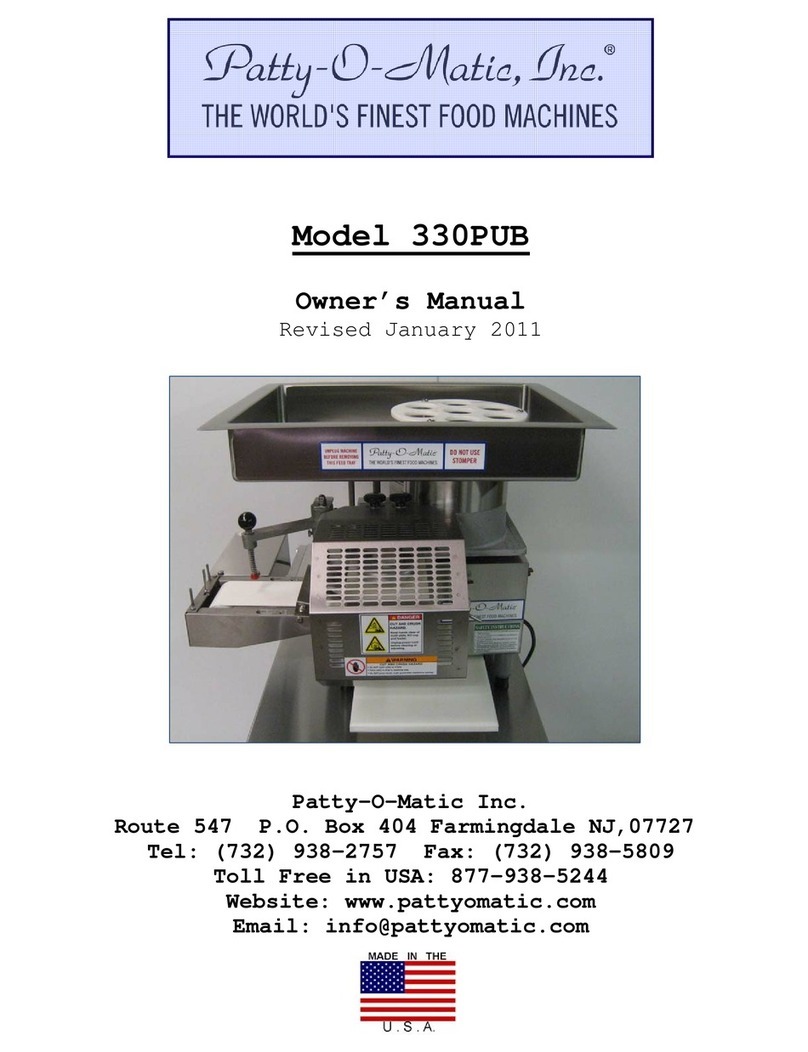

Patty-O-Matic 330PUB User manual

Patty-O-Matic

Patty-O-Matic 330A User manual

Patty-O-Matic

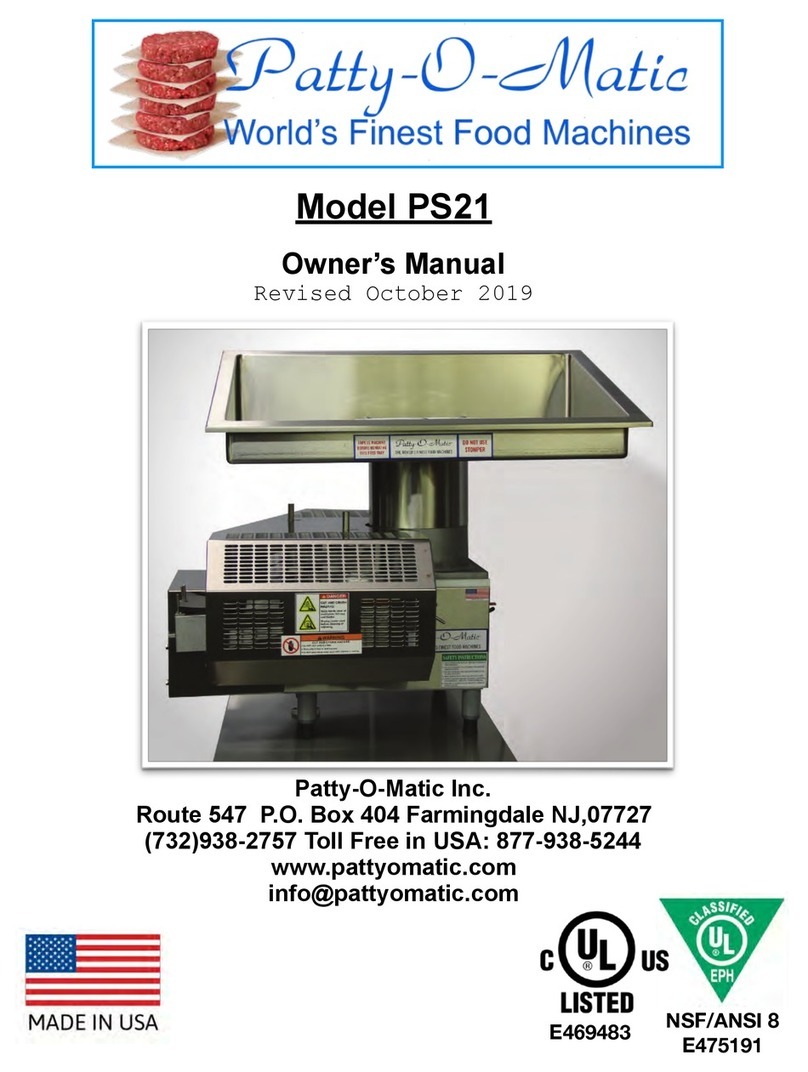

Patty-O-Matic PS21 User manual

Patty-O-Matic

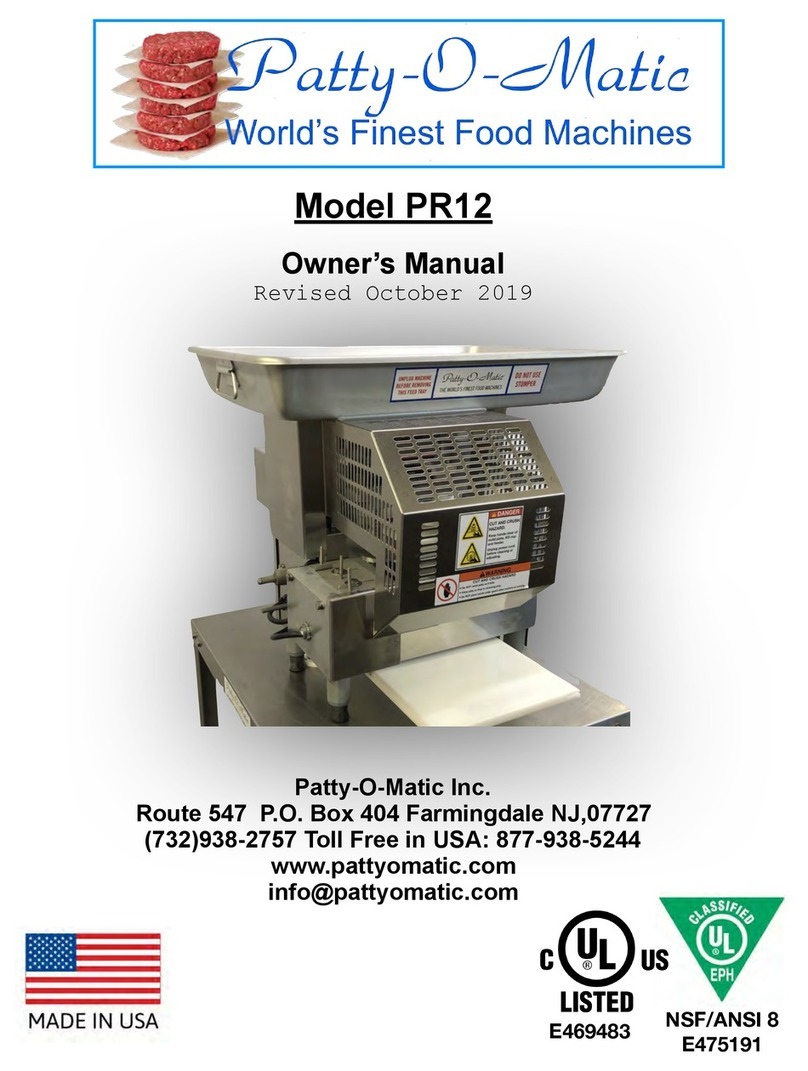

Patty-O-Matic PR12 User manual

Patty-O-Matic

Patty-O-Matic 330A User manual

Patty-O-Matic

Patty-O-Matic Pacesetter User manual

Patty-O-Matic

Patty-O-Matic Protege User manual

Popular Commercial Food Equipment manuals by other brands

Market Forge Industries

Market Forge Industries Universe Plus STGL Series Installation operation & maintenance

Daub

Daub D/ Cross Slicer 208 Information sheet

Diamond

Diamond FLAV-R-SAVOR FSHC-6W Series Installation and operating manual

Duke

Duke HOT/FROST HF35-2 Installation and operation manual

ARTEZEN

ARTEZEN Calybra Translation of the original instructions

Hatco

Hatco Glo-Ray 2-Go GRS2G Series Installation and operating manual

INTERNATIONAL CARBONIC

INTERNATIONAL CARBONIC PREMIER 2000 Service and installation manual

sinmag

sinmag SM-120a Operation manual

ACP

ACP AXP20 instruction sheet

Bartscher

Bartscher 700378G instruction manual

CARTER-HOFFMANN

CARTER-HOFFMANN LOGIX9 Series Owner's/operator's manual

croydon

croydon RDACO instruction manual