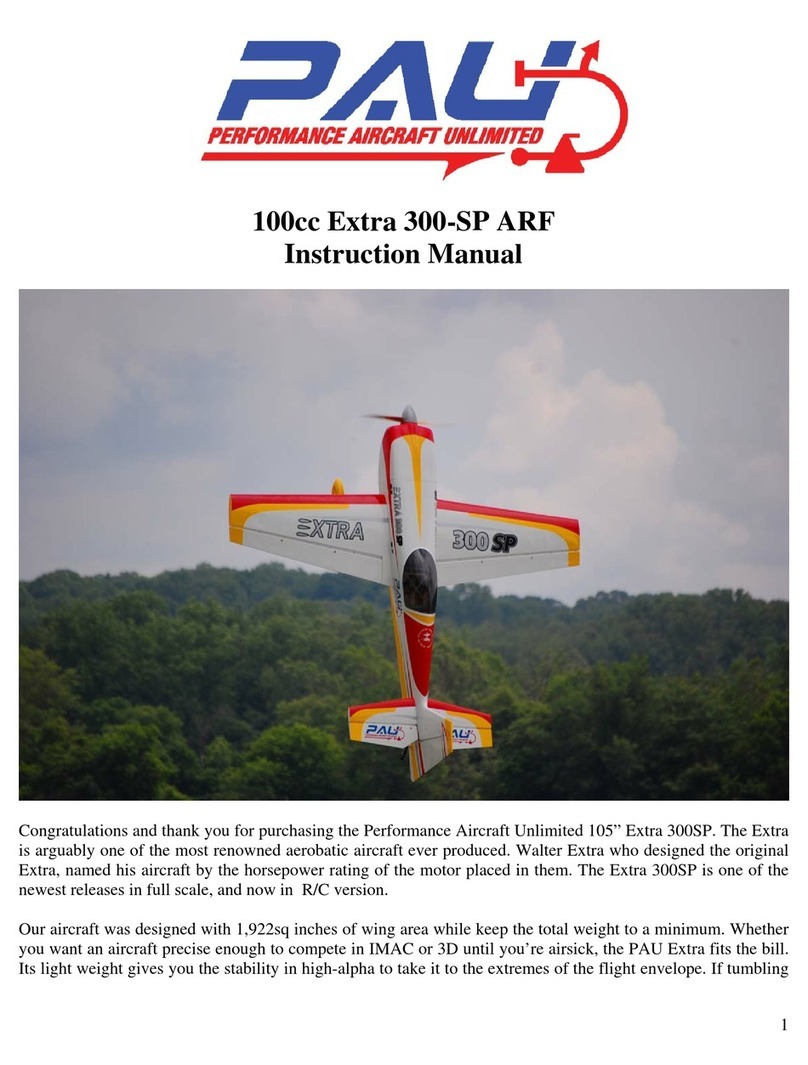

PAU 30% Sukhoi 26M User manual

Table of contents

Other PAU Toy manuals

Popular Toy manuals by other brands

GREAT PLANES

GREAT PLANES Ultimate Biplane EP ARF instruction manual

Faller

Faller Dunghill 130529 Assembly instructions

Acctron

Acctron Vertex-Link Mini user manual

The Learning Journey

The Learning Journey Techno Kids Around Town instruction manual

marklin

marklin 48291 instruction manual

KidKraft

KidKraft Everyday Heroes Assembly instructions

Troy Built Models

Troy Built Models BF-110C ZERSTORER instruction manual

Model Rockets

Model Rockets Super CENTAURI Assembly instructions

Pacherie

Pacherie PCR-015 Assembly instructions

Horizon Hobby

Horizon Hobby E-FLITE Ultimate 3D BNF Basic instruction manual

Trix

Trix 15 001 manual

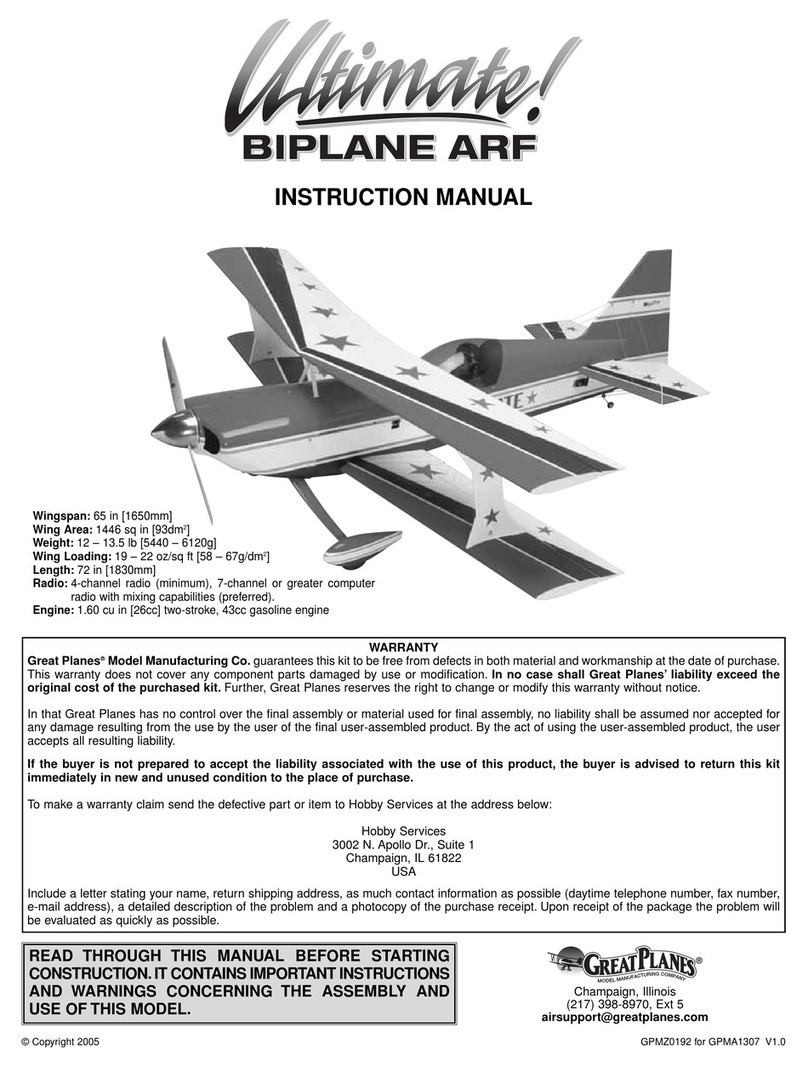

GREAT PLANES

GREAT PLANES ultimate! Instruciton manual

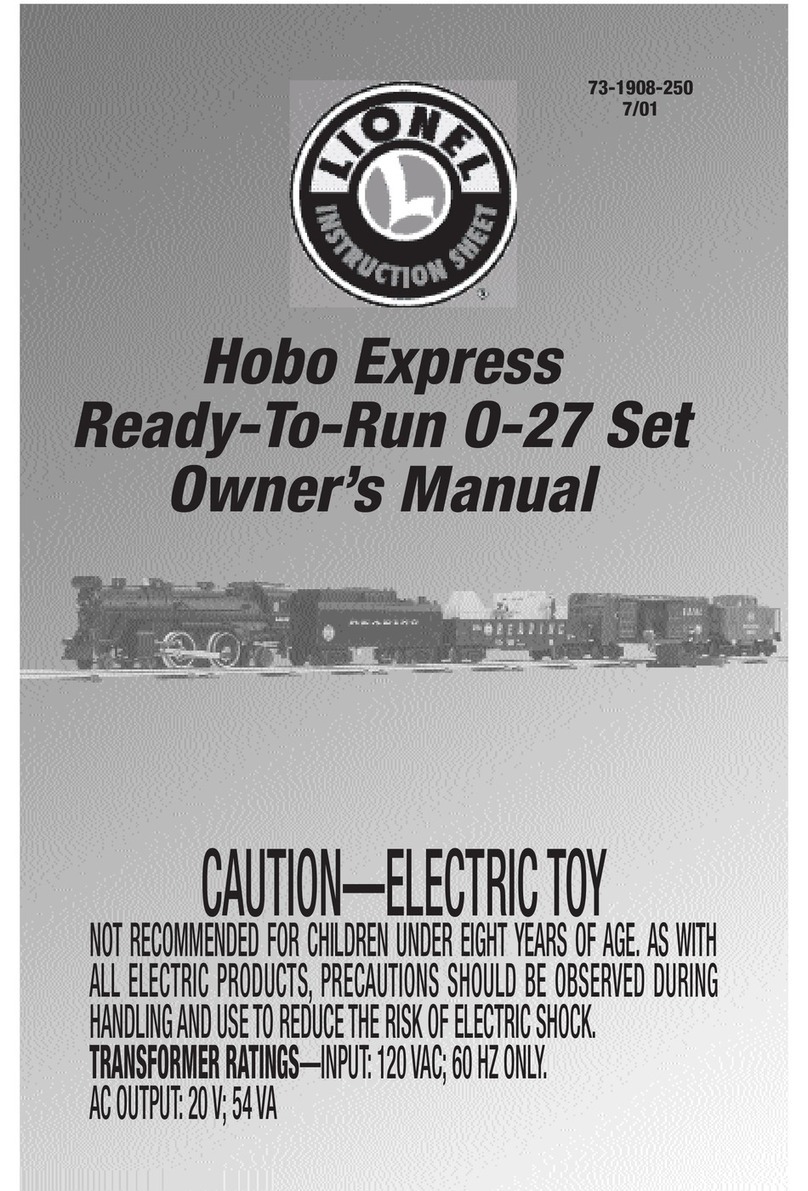

Lionel

Lionel HOBO EXPRESS owner's manual

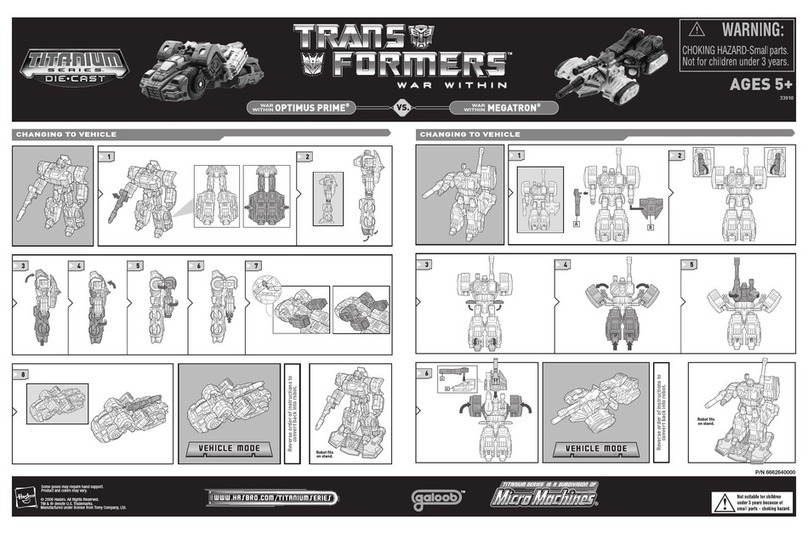

Hasbro

Hasbro Titanium War Within Optimus Prime vs.... manual

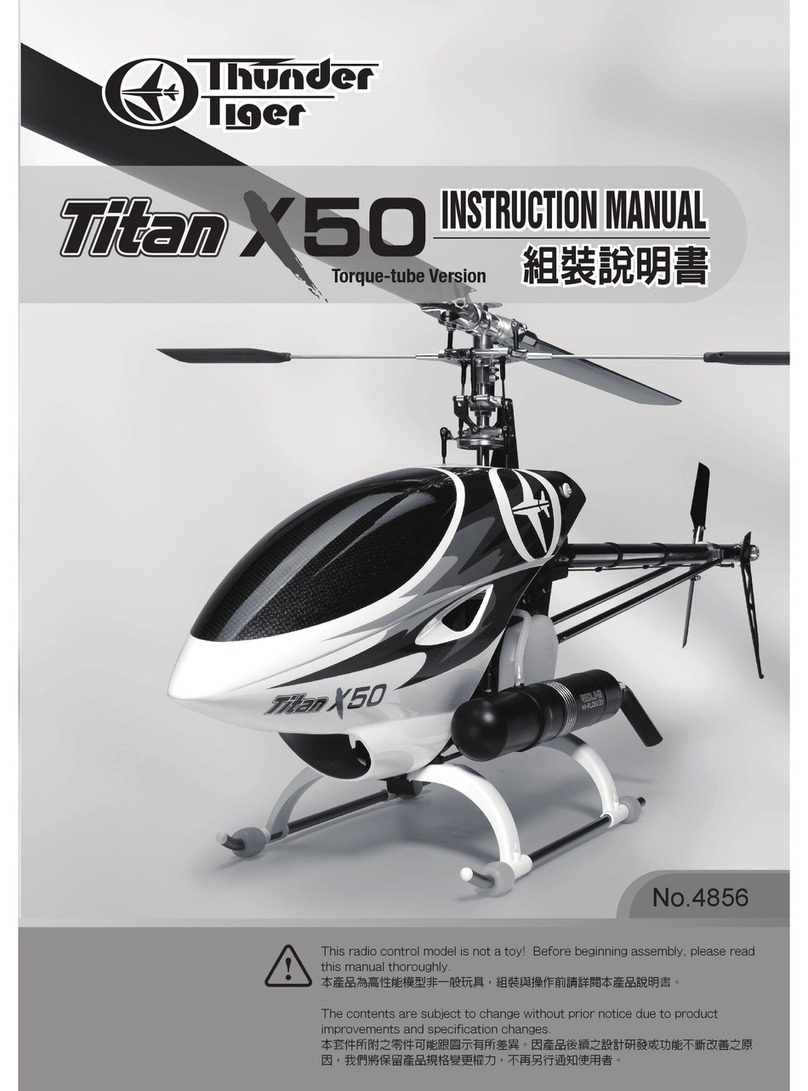

THUNDER TIGER

THUNDER TIGER TITAN X50 - instruction manual

Cobra

Cobra SRX8 instruction manual

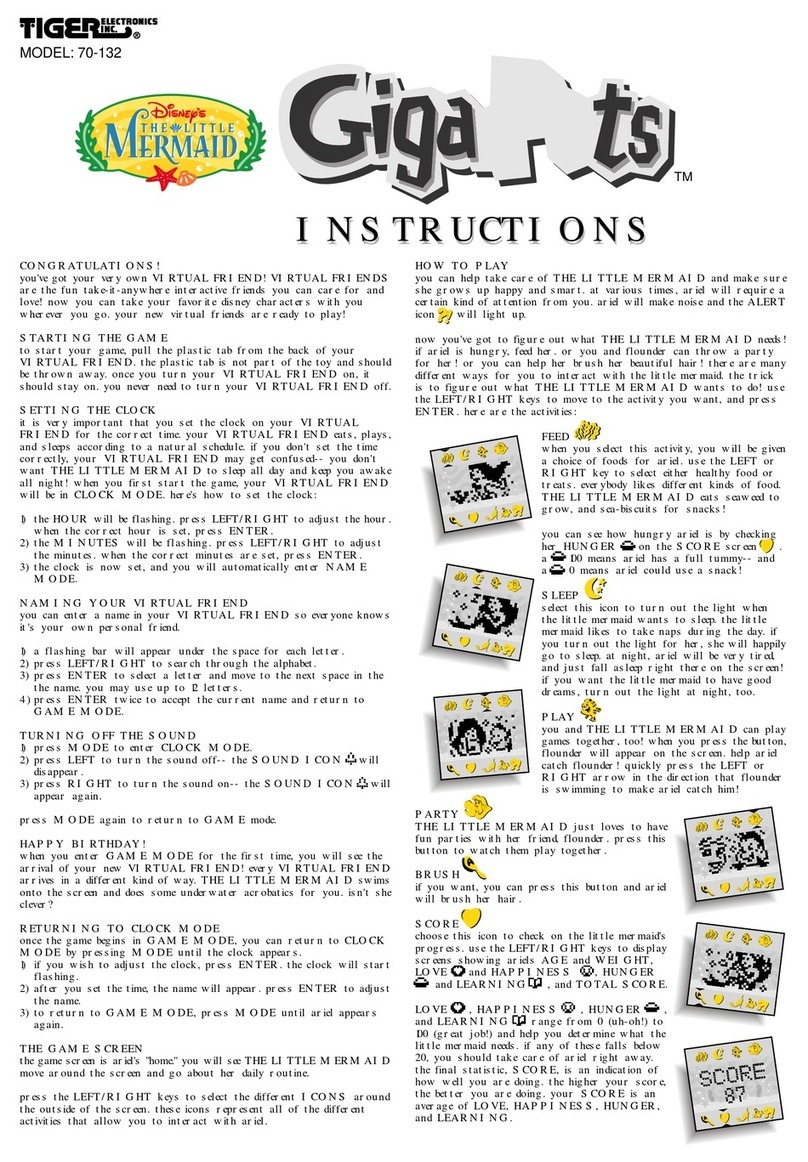

Tiger Electronics

Tiger Electronics Disney's Little Mermaid Gigapets 70-132 instructions

THE WORLD MODELS

THE WORLD MODELS Sky Walker EP instruction manual