1 General Information

2 9976x0210x-mub-en – V01 2020/09

Contents

1General Information.....................................................................................................3

1.1 About these instructions ...............................................................................................3

1.2 About this product ........................................................................................................3

1.3 Designated use ............................................................................................................4

2Safety instructions .......................................................................................................5

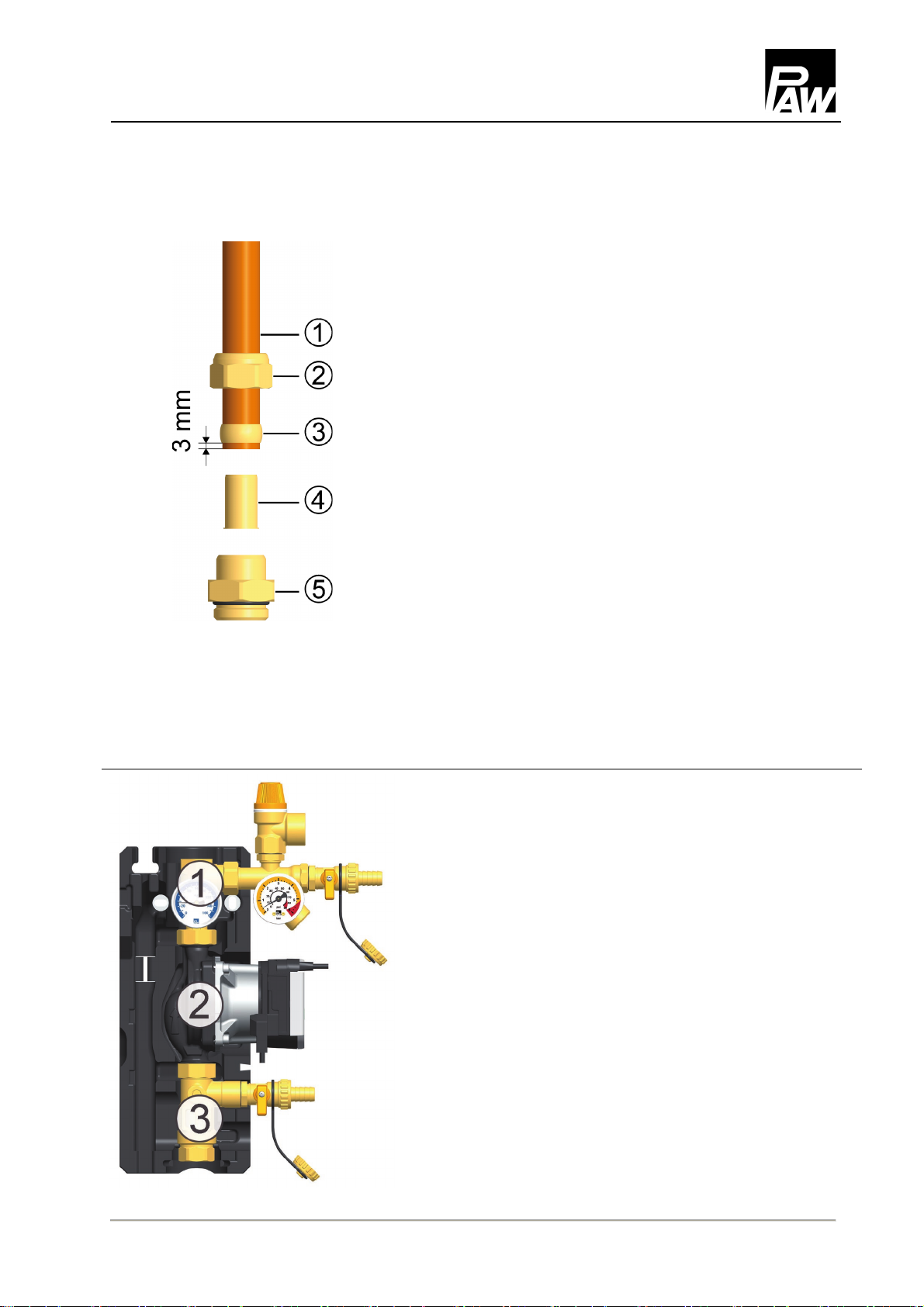

3Mounting and installation [specialist] .............................................................................7

4Commissioning [specialist] ...........................................................................................9

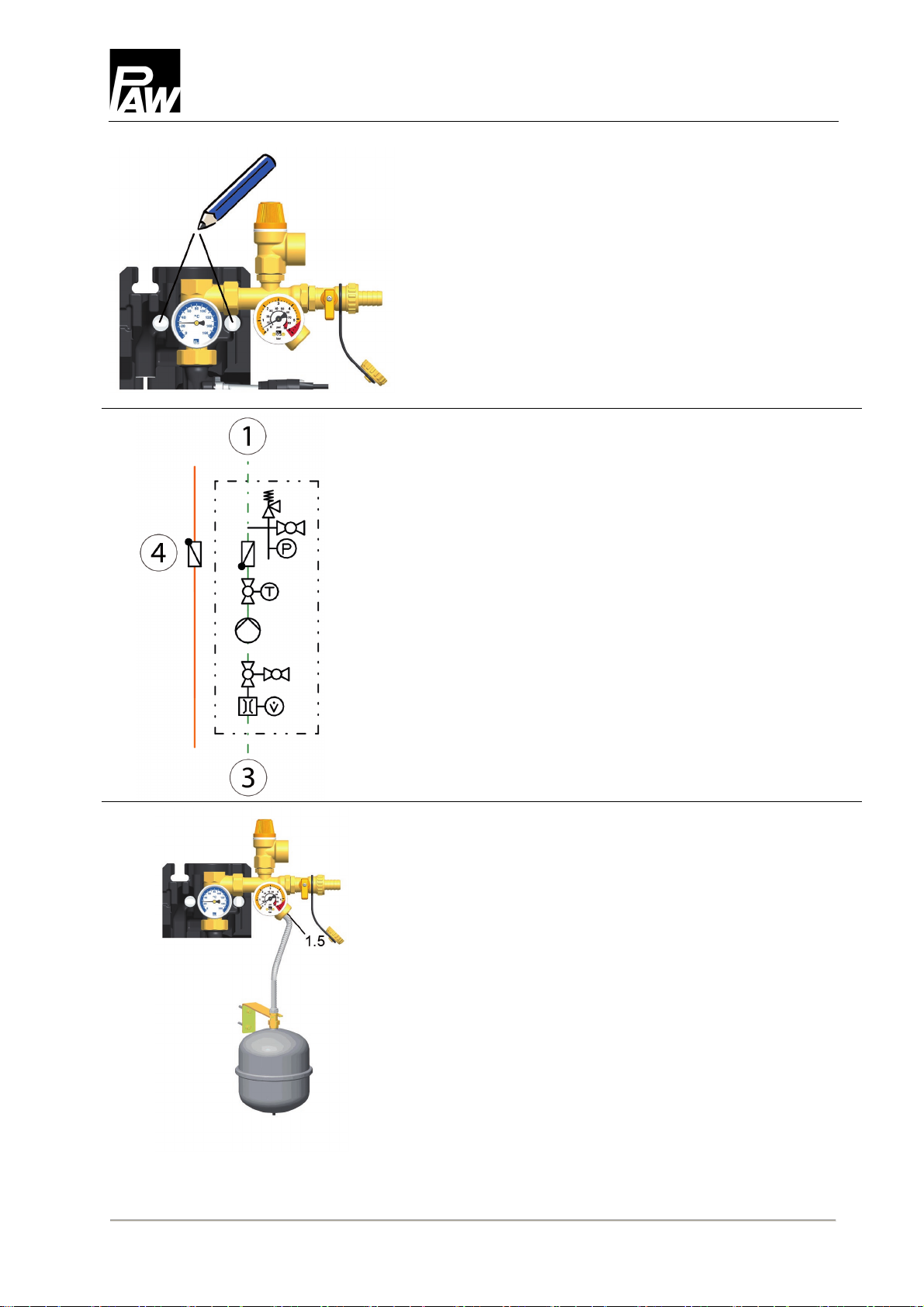

4.1 Preparations before flushing....................................................................................... 11

4.2 Flushing and filling......................................................................................................11

4.3 Setting the solar installation........................................................................................ 13

5Maintenance [specialist]............................................................................................. 14

5.1 Draining the solar system...........................................................................................14

5.2 Deinstallation.............................................................................................................. 14

6Spare parts [specialist]............................................................................................... 15

6.1 SolarBloC®midi Basic DN 20 ..................................................................................... 15

6.2 SolarBloC®maxi Basic DN 25 .................................................................................... 17

7Technical data and pressure drop characteristic curve.................................................. 19

7.1 Pressure drop and pump characteristic curve SolarBloC®midi Basic DN 20 .............. 21

7.2 Pressure drop and pump characteristic curve SolarBloC®maxi Basic DN 25 ............. 21

8Commissioning report ................................................................................................ 22

9Disposal ................................................................................................................... 23

Item no. 9976x0210x-mub-en – Version V01 – Issued 2020/09

Translation of the original instructions

We reserve the right to make technical changes without notice!

Printed in Germany – Copyright by PAW GmbH & Co. KG

PAW GmbH & Co. KG

Böcklerstraße 11

D-31789 Hameln, Germany