Sequence of Operation

NOTE: Defrost control board is equipped with 5minute lockout

timer that is initiated upon any interruption of power.

Turn on power to indoor and outdoor units. Transformer is

energized.

These models utilize a 2-stage indoor themmstat. With a call for

first (low) stage cooling or heating, the outdoor fan and low-stage

compressor are energized. If low-stage cannot satisfy cooling or

heating demand, high-stage is energized by the second (high)stage

of the indoor thermostat. After the second stage is satisfied, the

unit returns to low-stage operation until second stage is required

again. When both, first and second stage cooling or heating are

satisfied, the compressor will shut off.

Cooling

With first stage cooling, Y and O are powered on; and with second

stage cooling, Y2, Y and O are powered on. The O energizes the

reversing valve, switching it to cooling position. The Y signal

sends low voltage through the safeties and energizes the TI

terminal on the circuit board. If the compressor has been off for 5

minutes, or power has not been cycled for 5minutes, the OF2 relay

and T2 temfinal will energize. This will close the contactor and

start the outdoor fan motor and compressor. When the cycle is

complete, Y is turned off, stopping the compressor and outdoor

fan. The 5 minute time guard begins counting. Compressor will

not come on until this delay expires. In the event of a power

interruption, the time guard will not allow another cycle for 5

minutes.

Heating

With first stage heating, Y is powered on; with second stage

heating, Y2 and Y are powered on. The Y signal sends low

voltage through the safeties and energizes the T1 terminal on the

circuit board. If the compressor has been off for 5minutes or

power has not been cycled for 5minutes, the OF2 relay and T2

terminal will energize. This will close the contactor and start the

outdoor fan motor and compressor.

When the cycle is complete, Y is turned off, stopping the

compressor nd outdoor fan. The 5minute time guard begins

counting. Compressor will not come on until this delay expires. In

the event of a power interruption, the time guard will not allow

another cycle for 5minutes.

Compressor Operation

The basic scroll design has been modified with the addition of an

internal unloading mechanism that opens a by-pass port in the first

compression pocket, effectively reducing the displacement of the

scroll. The opening and closing of the by-pass port is controlled

by an internal electrically operated solenoid. The modulated scroll

uses a single step of unloading to go from full c@acity to

approximately 67% capacity.

A single speed, high efficiency motor continues to run while the

scroll modulates between the two capacity steps. Modulation is

achieved by venting a portion of the gas in the first suction pocket

back to the low side of the compressor, thereby reducing the

effective displacement of the compressor.

Full capacity is achieved by blocking these vents, thus increasing

the displacement to 100%. A DC solenoid in the compressor

controlled by a rectified 24 volt AC signal in the external solenoid

plug moves the slider ring that covers and uncovers these vents.

The vent covers are arranged in such a manner that the compressor

operates at approximately 67% capacity when the solenoid is not

energized and 100% capacity when the solenoid is energized. The

loading and unloading of the two step scroll is done "on the fly"

without shutting off the motor between steps.

NOTE: 67% compressor capacity translates to approximately

75% cooling or heating capacity at the indoor coil.

The compressor will always start unloaded and stay unloaded for

five seconds even when the thermostat is calling for high stage

capacity.

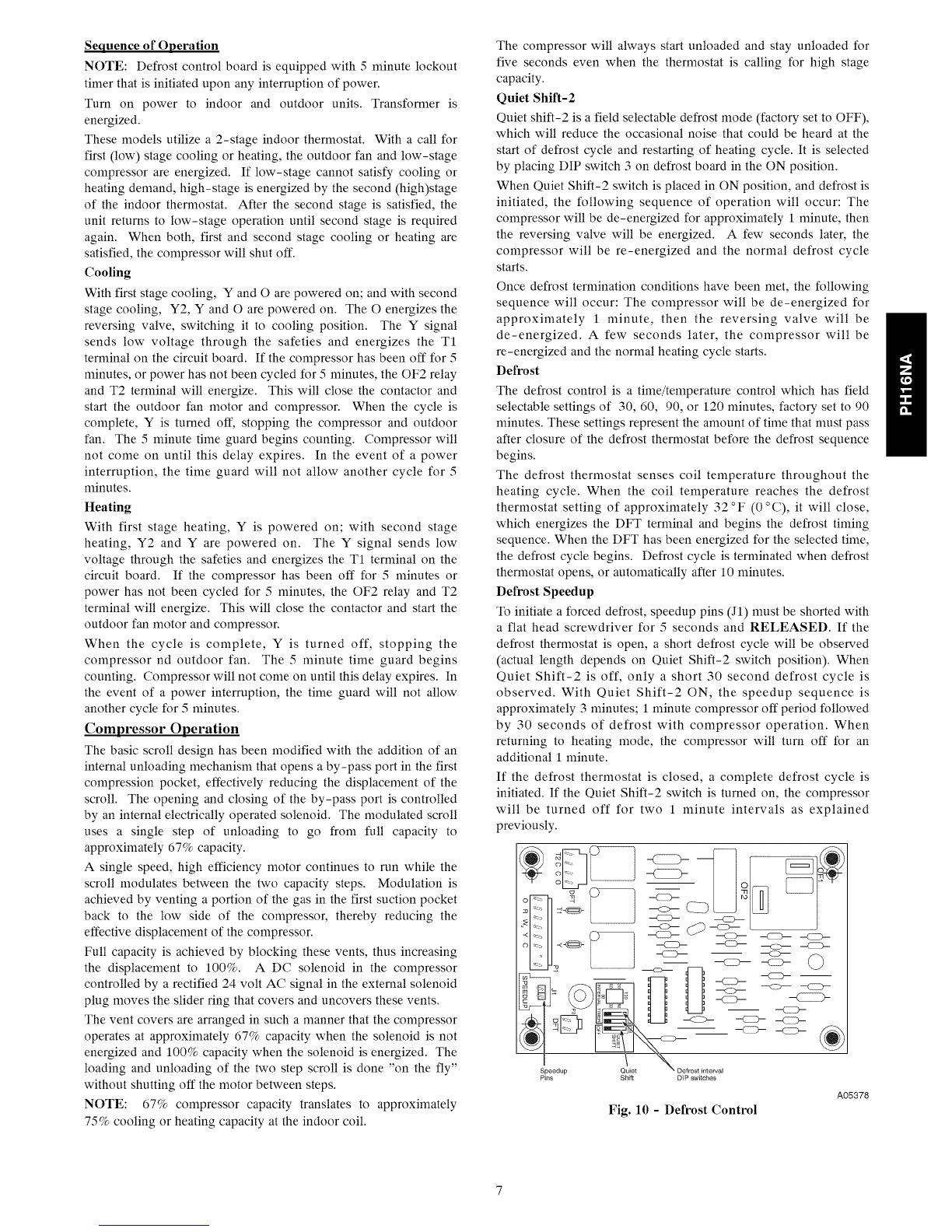

Quiet Shift-2

Quiet shift-2 is afield selectable defrost mode (factory set to OFF),

which will reduce the occasional noise that could be heard at the

start of defrost cycle and restarting of heating cycle. It is selected

by placing DIP switch 3 on defrost board in the ON position.

When Quiet Shift-2 switch is placed in ON position, and defrost is

initiated, the following sequence of operation will occur: The

compressor will be de-energized for approximately 1 minute, then

the reversing valve will be energized. A few seconds later, the

compressor will be re-energized and the normal defrost cycle

starts.

Once defrost termination conditions have been met, the following

sequence will occur: The compressor will be de-energized for

approximately 1 minute, then the reversing valve will be

de-energized. A few seconds later, the compressor will be

re-energized and the normal heating cycle starts.

Defrost

The defrost control is a time/temperature control which has field

selectable settings of 30, 60, 90, or 120 minutes, factory set to 90

minutes. These settings represent the amount of time that must pass

after closure of the defrost thermostat before the defrost sequence

begins.

The defrost thermostat senses coil temperature throughout the

heating cycle. When the coil temperature reaches the defrost

thermostat setting of approximately 32 °F (0 °C), it will close,

which energizes the DFT terminal and begins the defrost timing

sequence. When the DFT has been energized for the selected time,

the defrost cycle begins. Defrost cycle is terminated when defrost

thermostat opens, or automatically after 10 minutes.

Defrost Speedup

To initiate a forced defrost, speedup pins (Jl) must be shorted with

a fiat head screwdriver for .5 seconds and RELEASED. If the

defrost thermostat is open, a short defrost cycle will be observed

(actual length depends on Quiet Shift-2 switch position). When

Quiet Shift-2 is off, only a short 30 second defrost cycle is

observed. With Quiet Shift-2 ON, the speedup sequence is

@proximately 3minutes; 1 minute compressor off period followed

by 30 seconds of defrost with compressor operation. When

returning to heating mode, the compressor will turn off for an

additional 1 minute.

If the defrost thermostat is closed, a complete defrost cycle is

initiated. If the Quiet Shift-2 switch is turned on, the compressor

will be turned off for two 1 minute intervals as explained

previously.

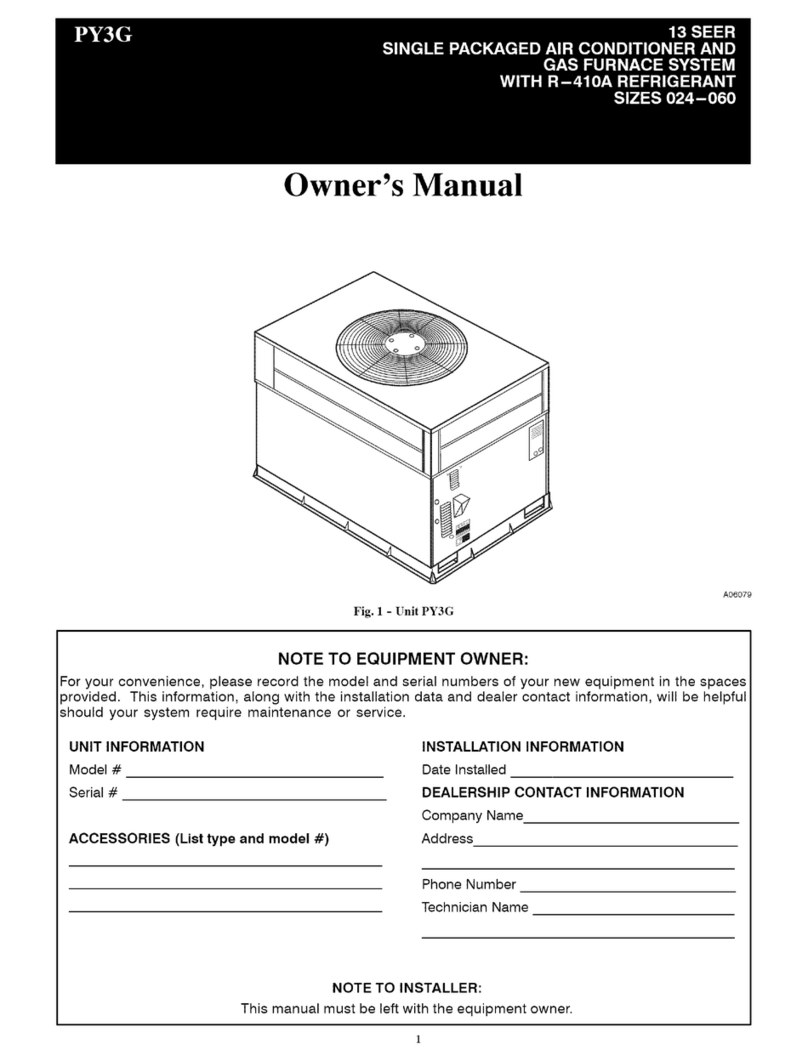

Speedup

Pins Shift D] P s_v]tches

A05378

Fig. 10 - Defrost Control