PBI PYRAMID User manual

International pbi S.p.A Instruction Manual 29/08/05 Rev. 11

“PYRAMID” Flowcheck System

Code n. 86666

I

IN

NS

ST

TR

RU

UC

CT

TI

IO

ON

N

M

MA

AN

NU

UA

AL

L

International PBI S.p.A. Via Novara, 89 – 20153 Milano – Italy – Tel + 39 02 48779-1 – Fax + 39 02 40090010

International pbi S.p.A Instruction Manual 29/08/05 Rev. 12

INSTRUCTION MANUAL

READ THIS BOOK CAREFULLY

It is intended to help you operate and maintain your new instrument properly.

Keep it handy for answers to your questions.

IMPORTANT SAFETY INSTRUCTIONS

When using this appliance, always exercise basic safety precautions, including the following:

•Use this appliance only for its intended purpose as described in this Use and Care book.

•This instrument must be properly installed in accordance with the Installation Instructions before it is used.

•Never unplug your instrument by pulling on the power cord.

•Always grip plug firmly and pull straight out from outlet.

•Repair or replace immediately all electric service cords that have become frayed or otherwise damaged. Do not

use cord that shows cracks or abrasion damage along its length or at either the plug or connector end.

•When moving your instrument away from wall, be careful not to roll over or damage the power cord.

•Unplug your instrument:

A. Before making any repair.

Note: We strongly recommend that any servicing be performed by a qualified individual.

B. Before cleaning.

C. Before replacing any accessories.

•Do not operate your instrument in the presence of explosive fumes.

When a standard two-prong wall outlet is encountered, it is your personal responsibility and obligation to have it

replaced with a properly grounded three-prong wall outlet.

Warning

Fire or electric shock hazard, do not expose this product to rain or moisture.

This unit contains dangerous voltages. NEVER remove cover unless qualified to do so

CAUTION DURING INSTALLATION

CAUTION

This unit must be grounded.

The power cord set provided is of the pattern often found in the market area, although

this is by no means universal, but many other patterns are used around the world.

If the plug is not compatible with the socket outlet available, it will be necessary to

obtain a suitable alternative cord set with the correct colour cables connection. The

mains lead coloured green-and yellow must be connected to the ground terminal on the

new plug which is marked with the letter or the earth symbol ⊥or coloured green-and-

yellow.

CAUTION

Before connecting the instrument to a power supply check that the voltage and

frequency details shown on the rear identification label are compatible with your main

supply.

N.B. The equipment must only be connected to a protectively grounded mains supply.

In the event of any uncertainty it is recommended that a qualified electrician be

consulted.

CAUTION

If using a maine supply without a protective earth. Before plugging in the unit, the

ground terminal close to the mains cable on the rear of the apparatus, must be connected

via a 2,5 mm2stranded wire to a safe earth. This work must be done by an authorised

electrician.

Prior to operation always ensure that the ventilation grids of the instrument are not

obstructed and that it is not positioned directly against a wall.

International pbi S.p.A Instruction Manual 29/08/05 Rev. 13

INDEX

1. Introduction ……………….……………………………………….…..pg. 4

2. Technical specification ………..…………………...…………………. pg. 4

3. Component of the “Pyramid” system ………..……………….…...…. pg. 5

4. Preliminary inspection …………………………………….…....…….. pg.5

5. Installation ……………………………….…………………...………....pg.6

6. Operations …………………....……………………………………….. .pg. 7

7. Maintenance ………...………...………………..……………….……... pg. 7

8. Microbial air sampler control …….………...…...………………….... pg. 9

International pbi S.p.A Instruction Manual 29/08/05 Rev. 14

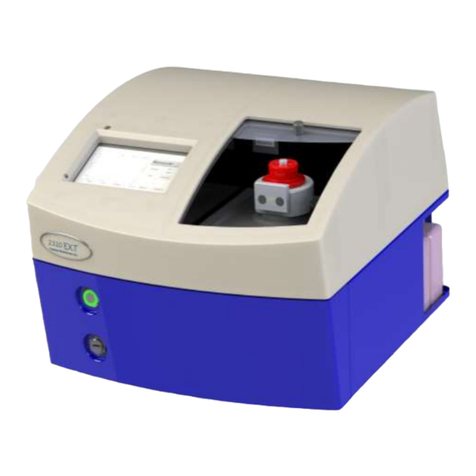

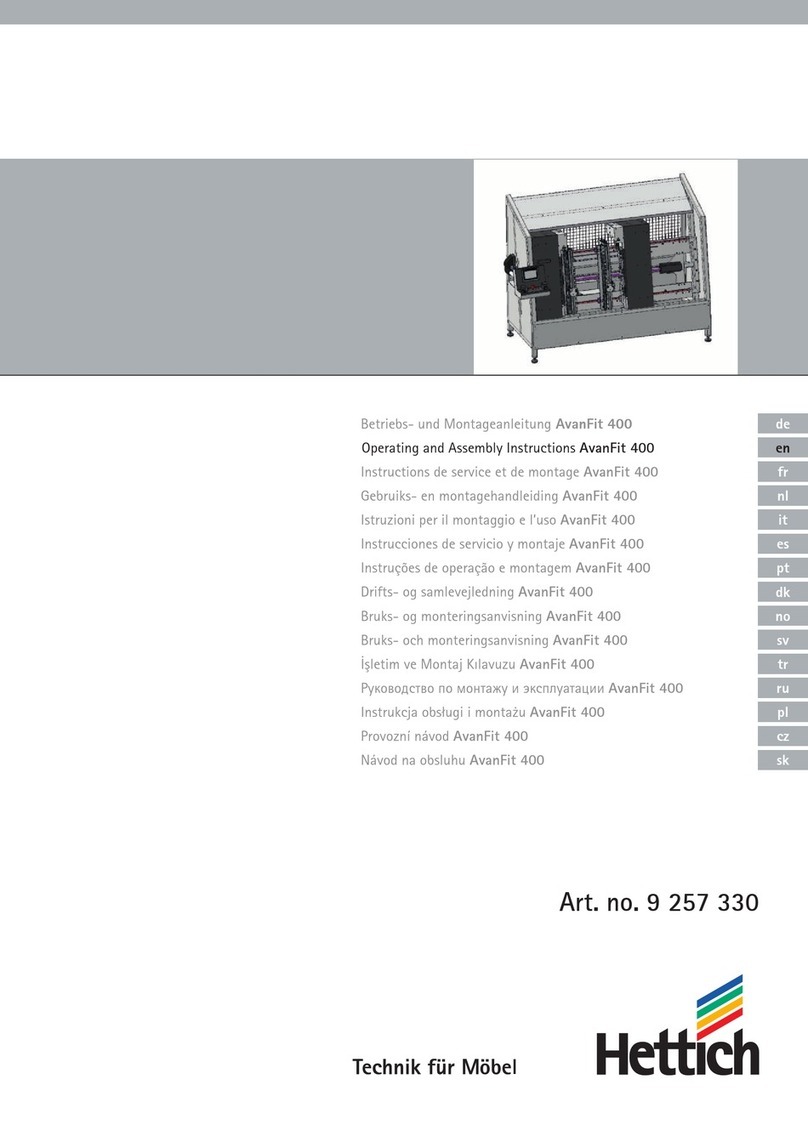

1. INTRODUCTION

The new “PYRAMID” flowcheck is a new easy-to-use, battery operated system that is applied to calibrate all the air

samplers of the “SAS” family.

This instrument is composed of two separate units, a fan and a flowmeter. The perfect balanced fan has a special

rubidium-made bearings that generate an electromagnetic field proportional to the fan speed. The flowmeter measures

this electromagnetic field and then calculates the exact air flow that is passing through the fan.

The “Pyramid” flowcheck system can display the airflow either in litres per minutes (L) or cubic feet per minute (CF).

The precision of the measured value is for “SAS Super 100” air sampler +/- 3 litres, for “SAS Super 180” air sampler

+/- 4 litres.

The internal battery life is approximately 3 years under normal operative conditions.

2. TECHNICAL SPECIFICATIONS

Weight:890 grams

Measurement range: 70-200 litres per minute

Suggested operational temperature: +20°C (+/- 2°C)

Power supply: 3V type CR2032 lithium battery. The normal battery life is 30.000 measurements of 60 seconds

Reading: The LCD display can show the results in litres per minutes (L) or cubic feet per minute (CFM).

International pbi S.p.A Instruction Manual 29/08/05 Rev. 15

3. COMPONENTS OF THE “PYRAMID” SYSTEM

The “Pyramid” system consists of 4 separate parts:

(a) the anemometer

(b) the flow sensor with LCD display

(c) the vertical wind tunnel

(d) the Instruction Manual with record documentation

It is recommended that this scientific system is treated with care and attention in order to maintain its precision.

4. PRELIMINARY INSPECTION

4 The apparatus is subject to specific working tests before shipping and it is carefully packed to avoid possible damage

during transit. However, a visible check should be carried out as soon as possible to determine any transit damage. This

must be reported immediately. The following procedures should be followed to check that the unit is functioning

correctly.

International pbi S.p.A Instruction Manual 29/08/05 Rev. 16

5. INSTALLATION

Anemometer installation

1. Screw the impeller anemometer (a) on top of the aluminium vertical wind tunnel.

Flow sensor installation

2. Fix the flow sensor with LCD display (b) on side of the aluminium vertical wind tunnel.

Vertical wind tunnel installation

3. The battery pack of the “SAS” air sampler instrument to be checked must be charged for at least 14 hours before the

test (3.5 hours if fast battery charger is used).

4. The “SAS” air sampler should be positioned in vertical position in a quiet place on a strong surface. Avoid current of

air around the instrument.

5. Program 1000 litres of air on the “SAS” air sampler and switch it on.

6. Position the “Pyramid” system (c) on top of the SAS air sampler.

7. Switch on the “Pyramid” system by briefly pressing the switch button of the flow sensor. The software version will

appear on the LCD display first, after which the instrument moves into the mode for measuring the current air flow

(litres per minute or cubic feet per minute). The measuring time is approximately 30 seconds to obtain a stable data

reading.

Unit of measurement choice

8. The LCD display switches to the converse version (L/minute or cubic meter per minute) by repeated pressing of the

push button.

Switch off of the unit

9. Hold the push button pressed down until the unit switches off.

International pbi S.p.A Instruction Manual 29/08/05 Rev. 17

6. OPERATIONS

The “SAS” air sampler should be positioned in vertical position in a quiet place on a strong surface. Avoid current of air

around the instrument.

2. Insert a Contact plate (RODAC plate) into the aspirating chamber of the air sampler and screw the aspirating head.

3. Program 1000 litres of air on the “SAS” air sampler and switch it on.

4. Position the “Pyramid” system (c) on top of the SAS air sampler.

5. Switch on the “Pyramid” system by briefly pressing the switch button of the flow sensor. The software version will

appear on the LCD display first, after which the instrument moves into the mode for measuring the current air flow

(litres per minute or cubic feet per minute). The measuring time is approximately 30 seconds to obtain a stable data

reading.

6. The LCD display switches to the converse version (L/minute or cubic meter per minute) by repeated pressing of the

push button.

7. Hold the push button pressed down until the unit switches off.

8. Record the lower and higher values on the record paper.

9. Repeat the operation from 3 to 6 ten times. Record the values of each cycle on the record paper and calculate the

average.

7. MAINTENANCE

In order to maintain its precision, it is recommended that the system is carefully treated.

The system doesn’t require special care and maintenance procedure. Clean the outside surface with a normal cloth.

Do not subject the system to sudden shock.

Battery replacement

It is suggested that the lithium battery 3V type CR2032 is replaced by servicing people or watch dealer.

(a). Unscrew the six screws of the metal back.

(b). Unscrew the screw of the battery cover.

(c). Remove the cover and extract the lithium battery.

(d). Put in the new battery observing the polarity (+ upwards). Screw back the battery cover. Make sure that the tiny

tongue in the centre of the top is raised so that it touches the metal back.

(e). Before refitting the metal back cover, make sure that the seal is clean and securely positioned in its slot.

(f) Refit the back and screw its six screws.

WARRANTY

WARRANTY CONDITIONS

International pbi warrants this product to be free of defects in materials and functionality.

The repairs will be effected by International pbi or by authorized dealers as follows:

- Faulty components free replacement

The labour is always at customer's expense

- The equipment will be sent at buyer's expenses and risk and the return will be ex-works

- This warranty does not apply to damages resulting from tamperings,abnormal use and installation and does not

cover transport damages

- International pbi shall not be liable for any commercial damages, whether incidental, consequential or otherwise

derived from the use of instruments

International pbi S.p.A Instruction Manual 29/08/05 Rev. 18

ATTENTION

TO OUR NEW CUSTOMER

As a user of our equipment you are covered for a 12 month guarantee for all spare parts as a result of mechanical failure

of the machine during normal use. In order to provide you with first class service, it is essential for us to know all your

references and which equipment you have. We kindly ask you, therefore, fill in the attached guarantee and return the

card to us by first class mail.

A NOTRE NOUVEAU CLIENT

En tant que utilisateur de notre appareil vous êtes couvert par une garantie de 12 mois pour toutes pièces de recharge

eventuelles resultant de defauts mecaniques en utilisation normale. Dans le but de vous fournir un service impeccable il

est essenciel que nous sachions qui vous êtes, ou vous êtes situes et quel equipment vous possedez. Voudriez vous

remplir cette carte de garantie et nous la retourner.

Le service PBI peut vous proposer un service d’entretien vous assurant un fonctionnement parfait rapide en cas de

panne.

Votre distributeur local peut vous fornir tous renseignements au sujet de ce contrat d’entretien et des prix appliqués.

FUR UNSERE NEUEN KUNDEN

Für Benutzer unserer Apparate sind alle ersatzteilen die sich aus mechanischen Fehlern in normalen Gerbrauch

ergeben., für zen Monate garantiert.

Damit wir Ihnen einem erstklassigen Service dienen konnen, ist es unbedingnotwending, dass wir wissen wo Sie sind

und welches Gerat Sie haben. Darum bitten wir Sie, die beiliegende Garantiekarte auszufullen, und Sie uns per Post

zuzuschicken.

PBI bietet Ihnen auch einen vorbeugenden Kundendienst, um dafur zu sorgen, dass Ihre Apparate zu allen Zeiten in

Ordun sind, dass Sie regelmassig kontrolliert werden, einen Express –Krisen-Service, wenn ein Apparat ausfallt.

Ihr Verkaufs Agent hat alle Details des Service Kontraktes und kann Ihnen Preise offerieren.

A TODOS NUESTROS NUEVOS CLIENTES

El equipo adquirido por Vd. Está garantizado por doce meses contra cualquier defecto de fabricación que pudiera

producir avería durante el uso normal. Con el fin de poderle ofrecer un servicio eficiente, es esencial que sepamos su

nombre o razón social, dirección y equipo adquirido. Para ello, rogamos que por favor rellene el certificado de garantía

adjunto y nos lo envíe por correro certificado.

PBI también puede ofrecer un servicio postventa de mantenimiento preventivo para mantener el perfecto estado de

funcionamento de su equipo, asì como ofrecerle una atencion normal y un rapido servicio en el caso de que su equipo

falle.

International pbi S.p.A Instruction Manual 29/08/05 Rev. 19

MICROBIAL AIR SAMPLER CONTROL

DATE…………….. INSTRUMENT MODEL …… …………………. DATE OF LAST CONTROL……………. ………..

AVERAGE VALUE OF THE LAST CONTROL ………………………

55mm CONTACT PLATE (RODAC) 84mm CONTACT PLATE 90mm PETRI DISH

TEST Nº 1 2 3 4 5 6 7 8 9 10

LTS/MN

TEMPERATURE

LOCATION

AVERAGE

THE INSTRUMENT IS SUITABLE NOT SUITABLE NOTE…………………………………………………….

OPERATOR’S NAME……………………. …………………………………………………….

SUPERVISOR’S NAME…………………. …………………………………………………….

International pbi S.p.A Instruction Manual 29/08/05 Rev. 110

To the attention of: Technical department International pbi S.p.A.

Via Novara, 89 - 20153 - Milano - Tel + 39 02/48.779.1-Fax +39 02/400.900.10

AUTHORISATION RETURN NUMBER TO BE ASKED TO THE EXPORT DPT

Company:

Address:

City: Zip Code State

Phone Fax Email

Name to contact:

Lab/Division:

return request of technical service

Equipment:

Model Serial Number:

for calibration repair other (specify)

NOTE OF MALFUNCTIONING

ELECTRICAL PART

ELECTRONICAL PART

MECHANICAL PART

HYDRAULICS PART

NOTES:

ATTENTION: THE INSTRUMENT MUST BE SENT TO

INT.PBI C/O STATIM VIA SAN GIUSTO 85 20153 MILANO ITALY

SIGNATURE NAME DATE

Mod. PQ 09.9

International pbi S.p.A Instruction Manual 29/08/05 Rev. 111

International pbi S.p.A Instruction Manual 29/08/05 Rev. 112

DECLARATION OF CONFORMITY

International PBI S.p.A.

Via Novara, 89 - 20153 Milano

HEREBY DECLARES

under its sole responsibility that the following product

“PYRAMID” Flowcheck System

Art. 86666

§ conforms with the technical requirements of the following

directives

89-336 CEE, 92-31 CEE

§ and the following harmonized standards have been applied

EN55014

Milano, 29/08/2005 Managing Director

Roberto Ligugnana

This manual suits for next models

1

Table of contents

Other PBI Laboratory Equipment manuals