DRAFT MTSE IO&M Manual

ii

Paragon Controls Inc,

Rev J 2/3/2021

TABLE OF CONTENTS

1.

INTRODUCTION .............................................................................................................................. 1

1.1.

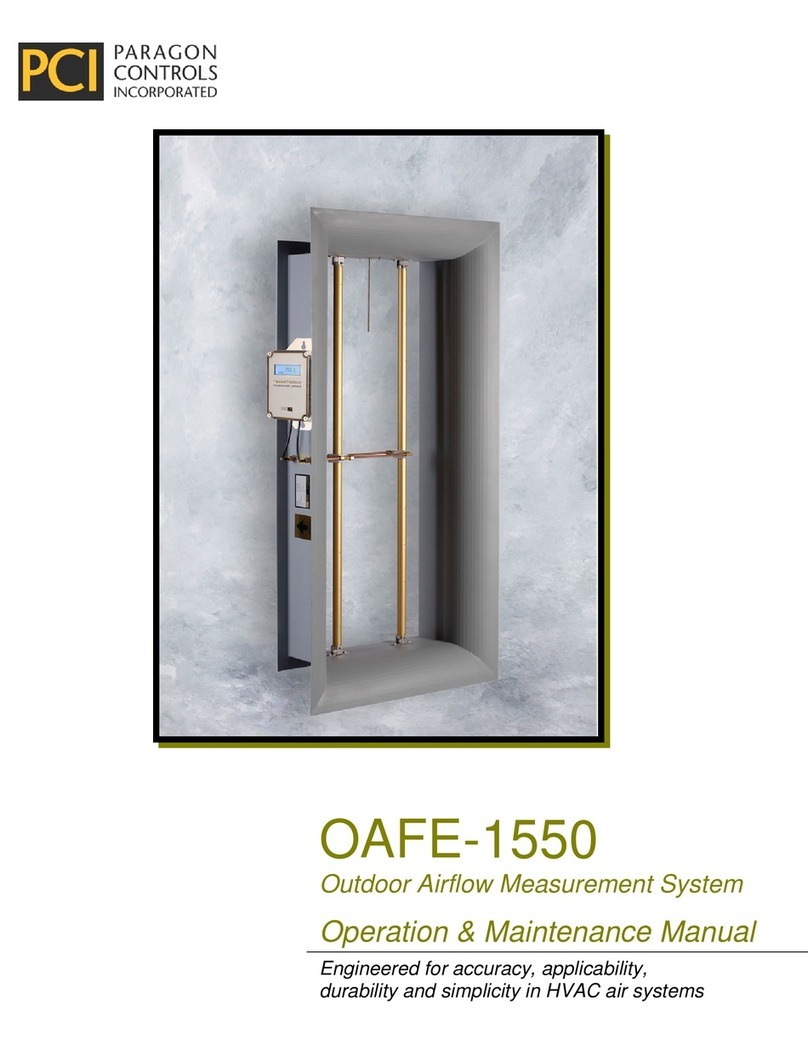

Description ................................................................................................................................... 1

1.2.

Specifications ............................................................................................................................... 1

1.3.

Safety ............................................................................................................................................ 1

1.3.1.

Electrical Connections .......................................................................................................... 1

1.3.2.

Static Electricity ................................................................................................................... 1

2.

INSTALLATION ............................................................................................................................... 2

2.1.

Product Installation Dimensions .................................................................................................. 2

2.2.

Electrical Connections.................................................................................................................. 3

2.2.1.

Common Electrical Connections .......................................................................................... 4

2.3.

Pneumatic Connections ................................................................................................................ 7

3.

MTSE CONFIGURATIONS .............................................................................................................. 8

3.1.

Display Overview ......................................................................................................................... 8

3.2.

System Configurations ................................................................................................................. 9

3.2.1.

Display Types ..................................................................................................................... 10

3.3.

Display Features ......................................................................................................................... 11

3.3.1.

Sensor Data Page Shortcut ................................................................................................. 11

3.3.2.

Keypad ................................................................................................................................ 11

4.

MENU INFORMATION .................................................................................................................. 12

4.1.

Levels of Menus ......................................................................................................................... 12

4.2.

Setup Menus ............................................................................................................................... 13

4.2.1.

Operating Range Menu ...................................................................................................... 15

4.2.2.

K-Factor .............................................................................................................................. 16

4.2.3.

Analog I/O Configuration .................................................................................................. 17

4.2.4.

System Filters ..................................................................................................................... 17

4.2.5.

Network Communications .................................................................................................. 18

4.2.6.

Temperature Compensation & Altitude ............................................................................. 19

4.2.7.

Alarm Options .................................................................................................................... 20

4.2.8.

Units and Precision ............................................................................................................. 22

4.2.9.

ΔP Settings ......................................................................................................................... 23

4.3.

Diagnostics Menu ....................................................................................................................... 24

4.3.1.

Sensor Data Page ................................................................................................................ 24

4.3.2.

System Overview ............................................................................................................... 26

4.3.3.

Factory Defaults ................................................................................................................. 27

4.3.4.

Software Update ................................................................................................................. 27

4.3.5.

ScreenSaver ........................................................................................................................ 28

4.3.6.

AutoZero Settings ............................................................................................................... 28

4.4.

K-Factor Page Shortcut .............................................................................................................. 29

4.5.

Notification Page ........................................................................................................................ 29

4.6.

Troubleshooting and Help Pages................................................................................................ 31

ATTACHMENTS

A BACnet PROTOCOL IMPLEMENTATION CONFORMANCE STATEMENT

B MODBUS SOFTWARE CONFIGURATION PARAMETERS