EFP-500 M0001-006 07/26/2011 - 3 -

Contents

1INTRODUCTION ..............................................................................................4

Labels, Symbols & Signal Words..................................................................................................4

Environmental Conditions..............................................................................................................4

Supply Ratings....................................................................................................................................4

2IMPORTANT INFORMATION .........................................................................5

Product Overview..............................................................................................................................5

Intended Use.......................................................................................................................................5

Instruction Manual ...........................................................................................................................5

Repair and Modification..................................................................................................................5

Safety Precautions............................................................................................................................6

3SETTING UP YOUR EFP-500..........................................................................7

Wall Mounting your EFP-500.........................................................................................................8

4OPERATION.....................................................................................................9

Start-Up ................................................................................................................................................9

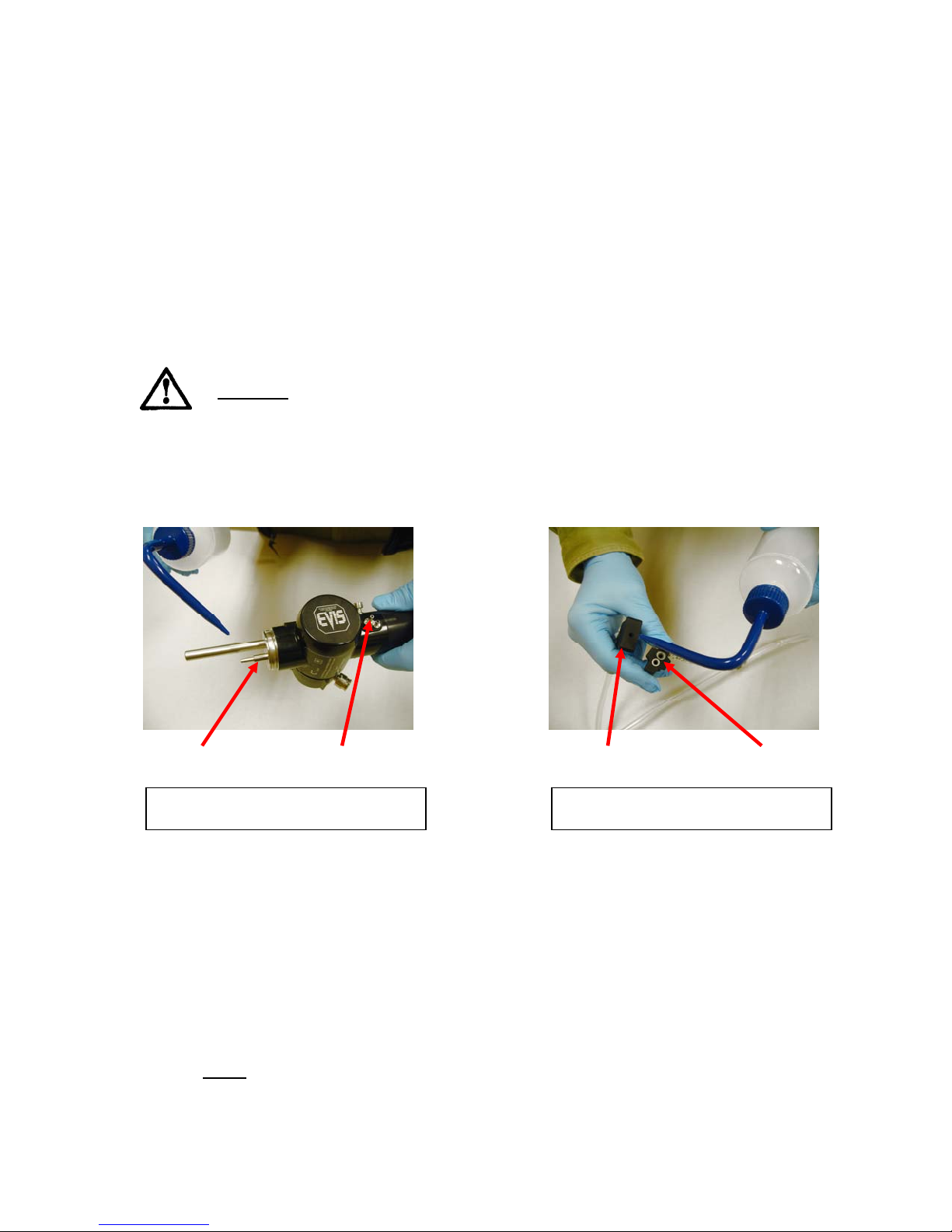

Connecting Your Endoscope to the EFP-500.........................................................................10

Channel Selection Process...........................................................................................................11

Flushing with Detergent...............................................................................................................12

Flushing with Water.......................................................................................................................13

Flushing with Air..............................................................................................................................13

Storage................................................................................................................................................13

5ROUTINE MAINTENANCE............................................................................14

Daily Maintenance ...............................................................................................................14

Monthly Maintenance..........................................................................................................14

6SYSTEM MAINTENANCE..............................................................................14

7DECONTAMINATION CYCLE.......................................................................14

A. EFP-500 Channel Assembly Decontamination ................................................................14

B. EFP-500 Decontamination.....................................................................................................15

8FLOW VERIFICATION..................................................................................16

9QUICK TROUBLESHOOT & FAQS................................................................17

Frequently Asked Questions........................................................................................................17

10 LIMITED WARRANTY...................................................................................18

11 COMPATIBLE ENDOSCOPES.......................................................................19

12 SPECIFICATIONS AND TECHNICAL DATA................................................19

Electrical:............................................................................................................................................19

Construction:.....................................................................................................................................19

Dimensions:.......................................................................................................................................19

13 REGISTRATION CARD .................................................................................19