MOST 20-2B

ii

PACIFIC CONSOLIDATED INDUSTRIES 350003 Rev D

SAFETY SUMMARY

The following are general safety precautions that are not

related to any specific procedure and therefore do not

appear elsewhere in this technical manual. These are

general safety precautions and instructions that people

must understand and apply during many phases of

operation and maintenance to ensure personal safety and

health and the protection of Government property.

Throughout this manual you will see three types of

notations which contain special information:

NOTE: Provides additional information that may be

helpful in performing a specific task.

WARNING: Provides information about conditions

which require special attention and precautions to

avoid serious injuries.

CAUTION: Provides information about conditions

which require special attention and precautions to

avoid equipment damage.

Be sure to read the information in the notes, cautions, and

warnings carefully, and consult someone experienced in

handling oxygen equipment about any issues that are

unclear. Additional safety guidelines related to specific

components of the MOST are described in the appropriate

chapters.

DANGEROUS PRESSURES

Care must be taken during operation to ensure that all

fittings are proper and tight. All system components must

be compatible with pressure applied. Personnel must be

protected by a minimum of safety glasses when transfilling

or repairing.

WORKING WITH OXYGEN

Oxygen used in the medical profession can be very

hazardous. Although oxygen does not burn, it does support

combustion. A Material Safety Data Sheet is available at

Pacific Consolidated Industries.

Oxygen systems must be properly cleaned and inspected in

accordance with Compressed Gas Association pamphlet

G-4.1 prior to use to ensure that no combustible materials

remain in the connecting piping and fittings. If you are not

familiar with oxygen cleaning procedures contact the

Compressed Gas Association or Pacific Consolidated

Industries prior to putting oxygen into your piping and

distribution system. The Compressed Gas Association’s

web site is www.cganet.com.

Observe strict cleanliness procedures when fabricating and

connecting the oxygen piping.

Only operate the oxygen equipment in a well-ventilated

area.

GUIDELINES FOR HANDLING

CYLINDERS

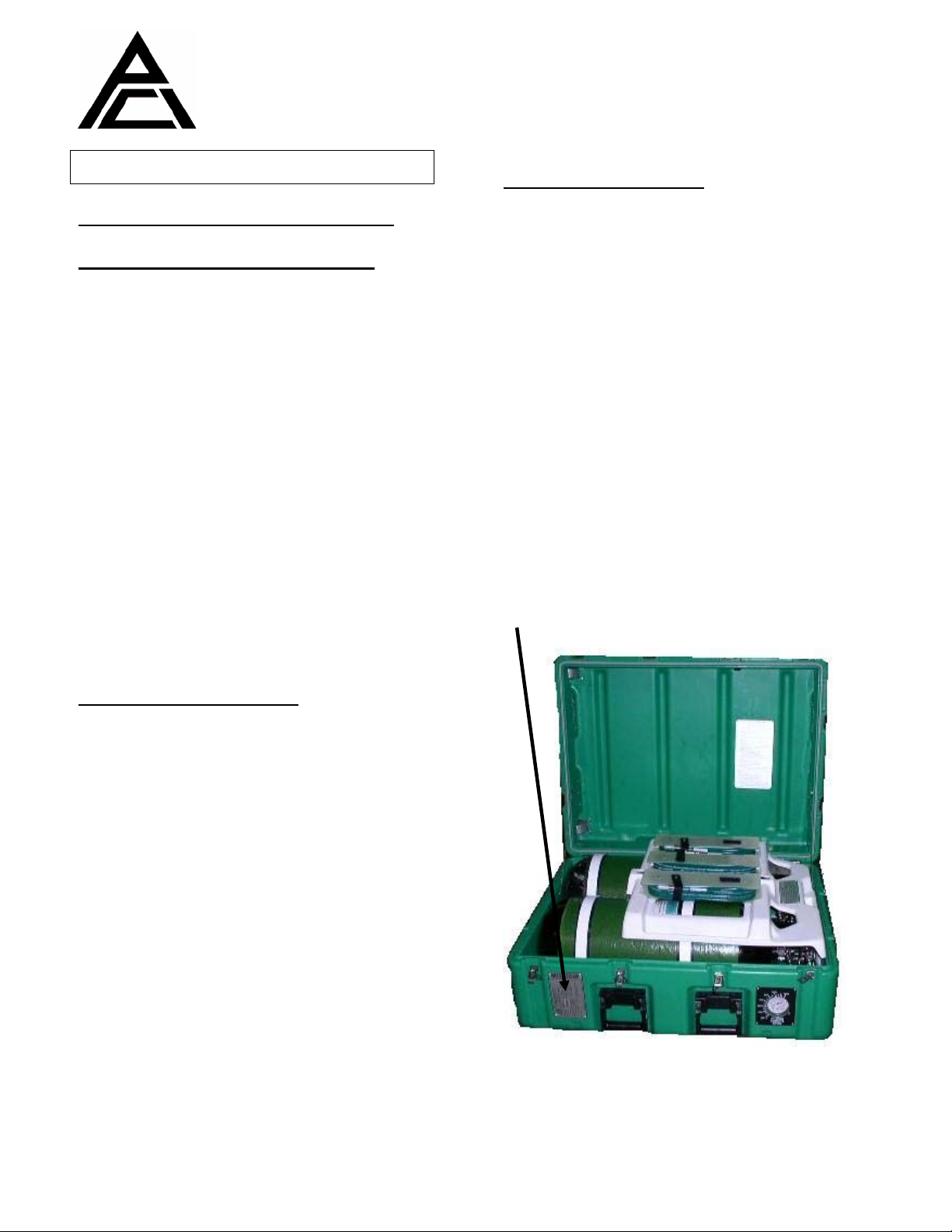

While the principal function of the MOST is to provide

gaseous oxygen for medical use, conventional oxygen

cylinders are still an integral part of the method for

supplying backup oxygen and for mobile oxygen

requirements (for example, on board ambulances).

Oxygen cylinders are under extremely high pressure (as

much as 2,250 psi) and present a number of associated

hazards as a result.

WARNING: The sudden release of this pressure,

whether by puncture, dropping, or loss of pressure

can easily turn the cylinder into a projectile

hurtling across the ground and through the air.

Take extreme care when filling cylinders and

when handling charged cylinders.

WARNING: Do not drag or slide cylinders or lift

them by the pressure cap; this may damage the

cylinders and cause the sudden release of,

cylinder pressure. Use a suitable hand truck,

forklift, roll platform, or similar device to move

cylinders.

WARNING: Do not drop cylinders or permit them

to strike against each other or other surfaces; this

may damage the cylinders and cause the sudden

release of cylinder pressure. Firmly secure

cylinders during moving and transport.

WARNING: Do not fill cylinders too rapidly.

Excessive heat may build up in the gas and result

in a failure of the seals in the cylinder valves and

possible ignition.